Electronic product reliability accelerated test method based on failure physics

An electronic product and accelerated test technology, which is applied in the direction of electrical digital data processing, special data processing applications, instruments, etc., can solve the problems of large error in test results, low model accuracy, and inability to consider stress transfer effects, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be described in further detail below. A method for accelerated reliability testing of electronic products based on fault physics, characterized in that: the steps for accelerating the reliability testing of electronic products are as follows:

[0034]1. Build digital prototype models of electronic products: digital prototype models refer to two-dimensional digital prototype models or three-dimensional digital prototype models, and electronic products include chassis, brackets, modules, circuit boards and components;

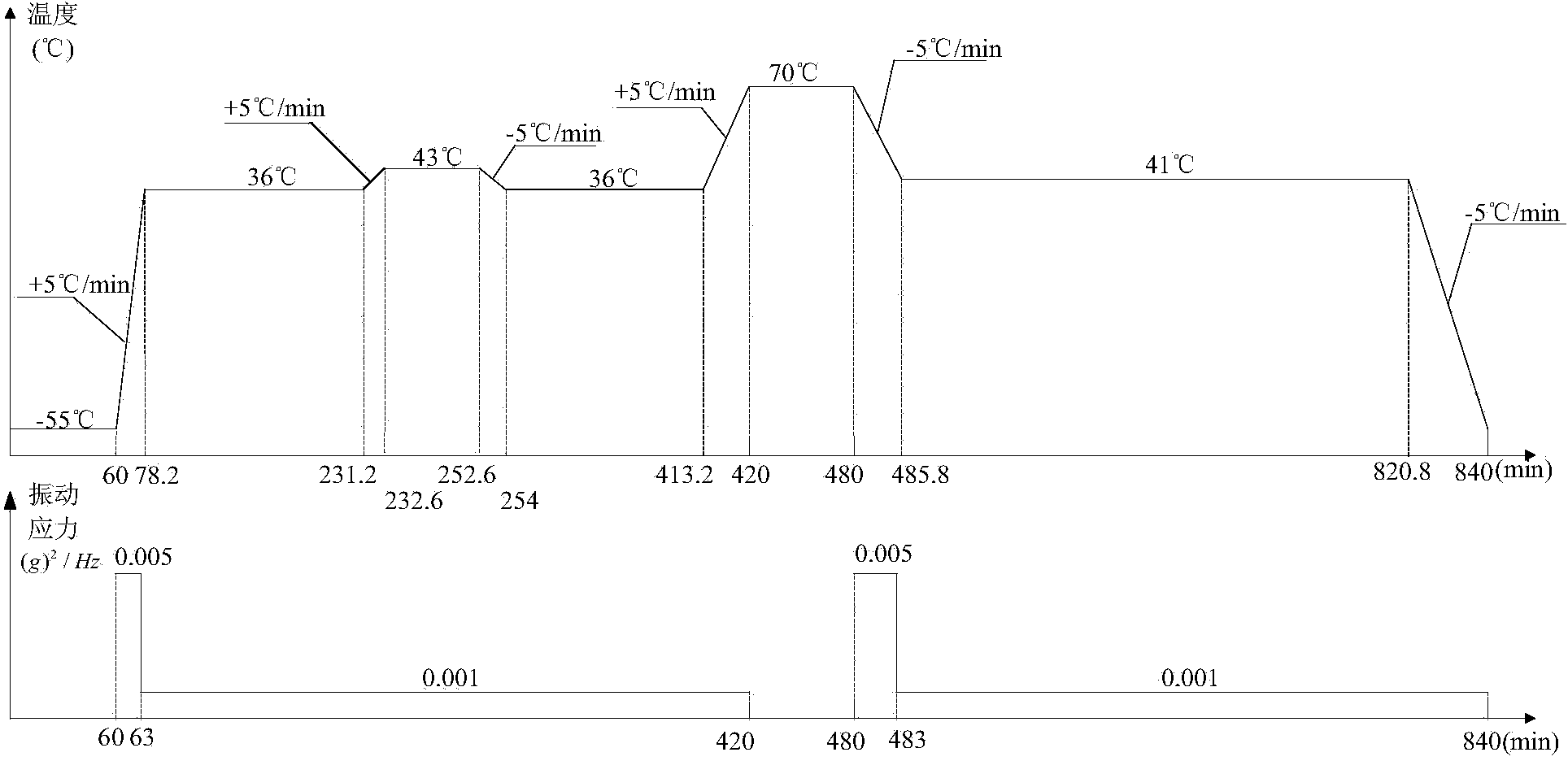

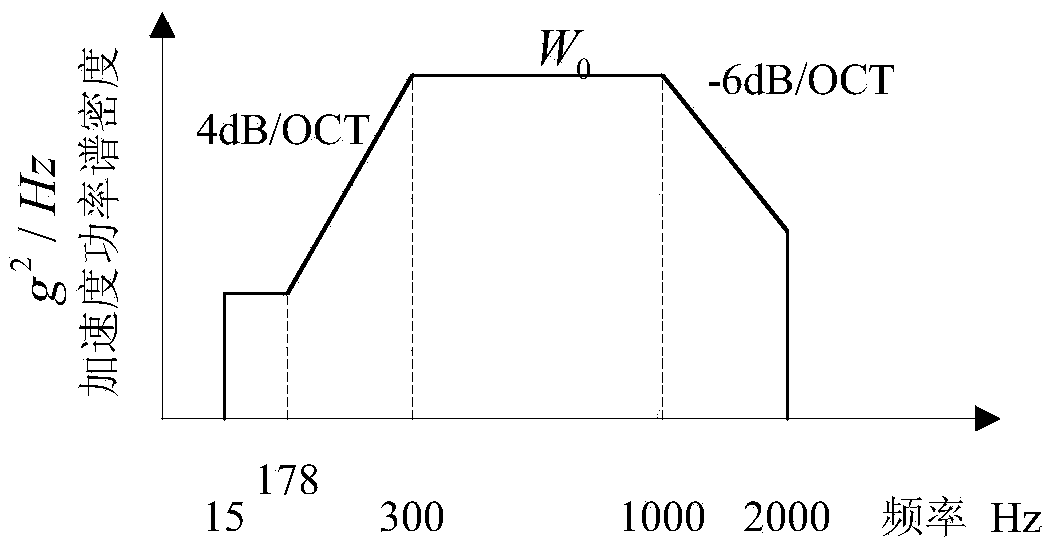

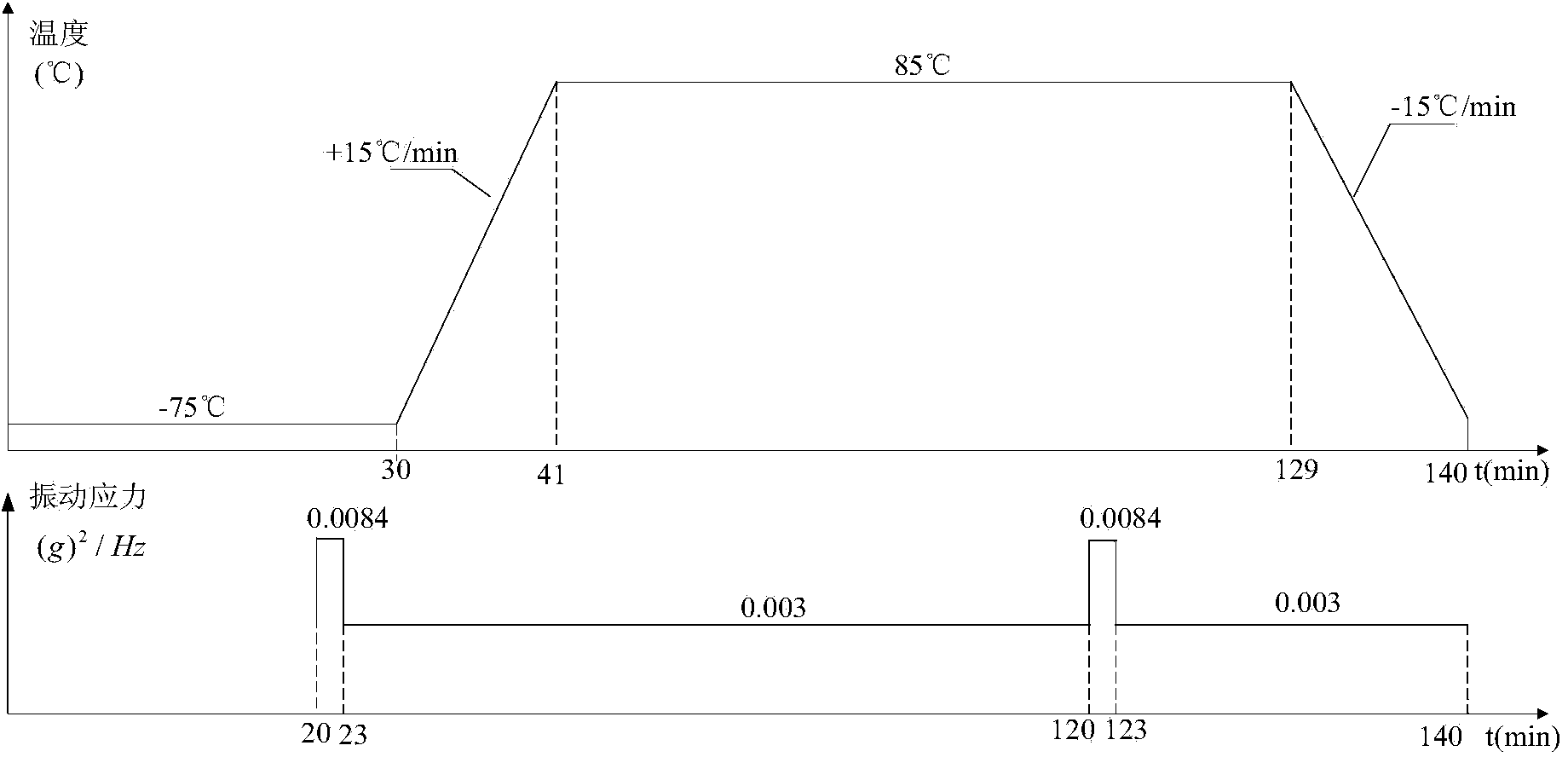

[0035] 2. Analysis of thermal stress state and vibration stress state: Use finite element simulation analysis software to analyze the thermal stress state and vibration stress state of electronic products under load conditions. The load conditions refer to environmental loads and working loads;

[0036] 3. Determine the failure mechanism of electronic products: According to the thermal stress state and vibration stress state of e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com