Alternating current servo motor assembly process with brake

An AC servo motor and assembly process technology, which is applied in the field of electric motors, can solve problems such as positioning errors, and achieve the effects of high positioning accuracy and improved installation accuracy errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

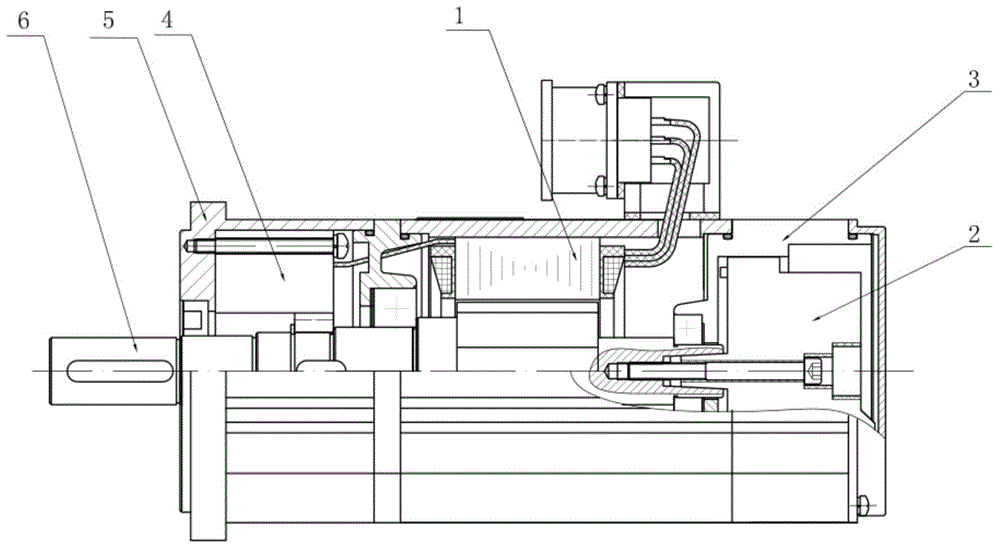

[0022] Below, further description will be made in conjunction with the accompanying drawings and the preferred embodiment.

[0023] like figure 1 As shown, by adjusting the installation position and order of the brake and the encoder on the motor body, the positioning accuracy of the zero point of the encoder relative to the magnetic steel position of the motor rotor is improved.

[0024] (1) Press-fit the stator winding into the motor casing; press-fit the front bearing of the motor rotor into the bearing chamber of the front end cover, at this time, the motor rotor passes through the stator winding; install the front end cover of the motor; install the rear end cover of the motor; Complete the installation of stator winding, rotor, front end cover and rear end cover first;

[0025] (2) Then connect the stator winding with 5V DC, in which the U phase of the stator winding is connected to the positive pole of the power supply, and the V and W phases are connected to the negat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com