Remote-control self-walking gas-suction comb-picking revolving-bowl conveyor-belt type sorting and grading pear picking machine

A technology of self-propelled air and conveyor belts, which is applied in the direction of picking machines, harvesters, agricultural machinery and tools, etc., can solve the problems of high labor intensity, labor and time, and achieve the effect of flexible picking and high picking efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

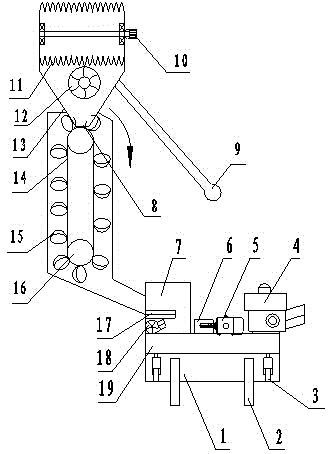

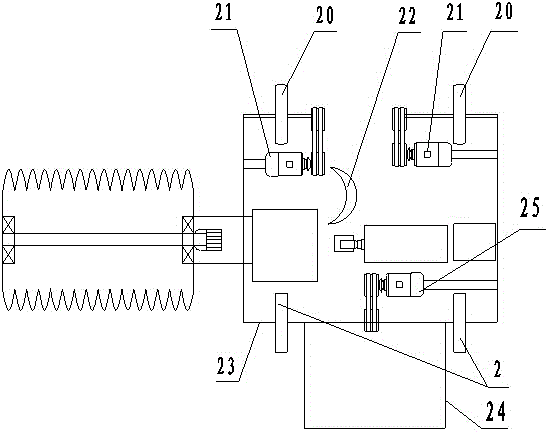

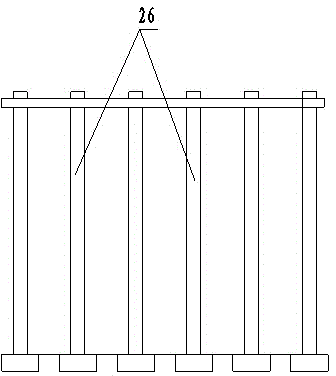

[0018] In the embodiments shown in 1 to 3, a remote-controlled self-propelled air-suction comb picking rotating bowl conveyor belt type clearing and grading pear picking machine includes a trolley 1, a gasoline generator 4, a motor 5, a hydraulic pump 6, and a comb picking machine. A picker, a conveying mechanism and a classification and cleaning mechanism, one end of the frame 23 is provided with a traveling wheel 2 and a thrust handle 24, and the other end is provided with a steering wheel 20, and the base of the double-acting lifting cylinder 3 is installed on the frame 23 of the trolley 1 On, the other end is fixedly connected with platform 19, drive motor 25 and steering motor 21 are installed on vehicle frame 23, drive motor 25 makes dolly 1 advance or retreat, and steering motor 21 makes dolly 1 turn left or right, and set on platform 19 There is a seat 22, and a remote control button is arranged on the seat 22 to control the movement of the trolley 1. The extension of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com