A device for realizing high-pressure torsion process on a hydraulic press

A high-pressure torsion, hydraulic press technology, applied in the driving device of forging press, forging/pressing/hammer device, forging/pressing/hammering machinery, etc., can solve problems such as uncontrollable speed, small torque, and inability to achieve precision forming. , to achieve the effect of enriching functions, expanding work scope and high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

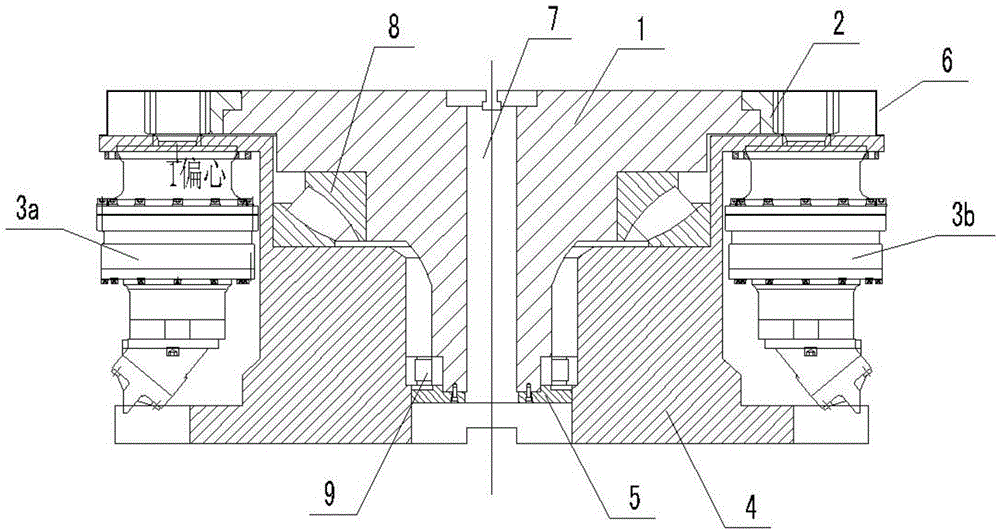

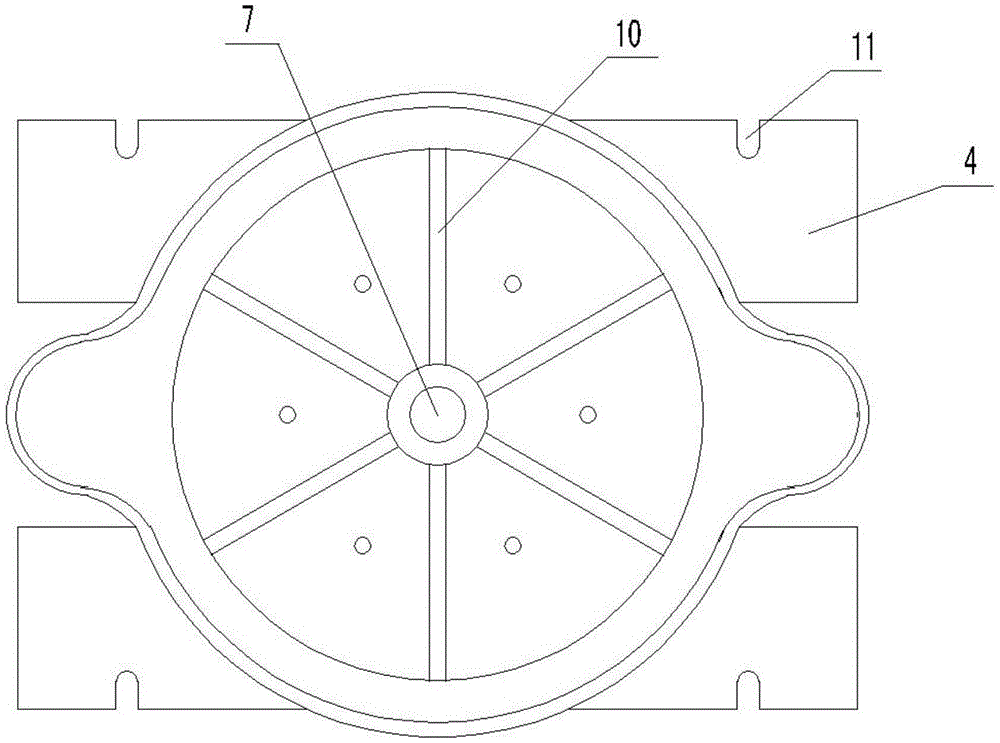

[0029] see figure 1 and figure 2 , the structural form of the device used in this embodiment to realize the high-pressure torsion process on the hydraulic press is:

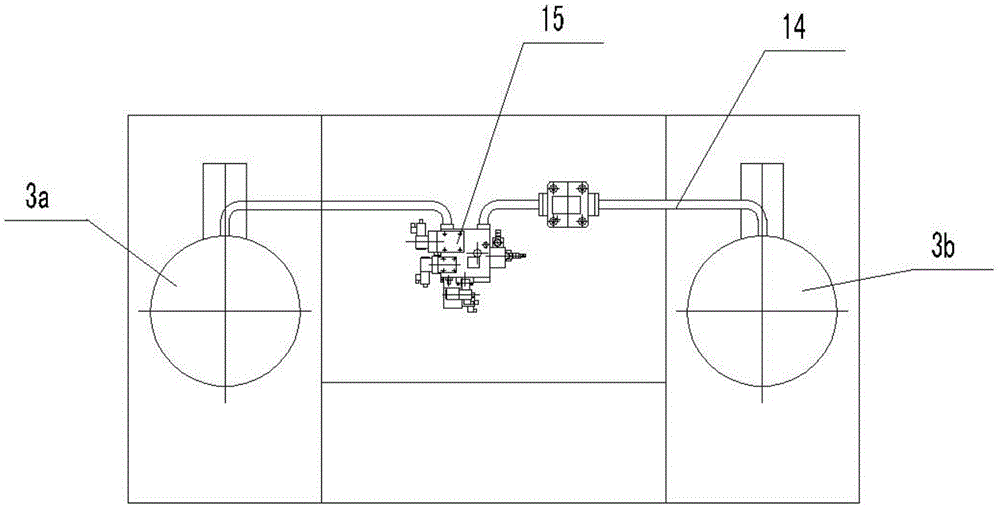

[0030] A turntable 1 is provided, and the turntable 1 is horizontally supported on the turntable base 4 through the centripetal bearing 8 on the waist outer circumference of the turntable 1, and the bottom centripetal bearing 9 passes through the sealing ring 5 to the turntable 1. The end surface of the bottom is supported in balance so that the central axis of the turntable 1 remains vertical, and the radial bearing 9 at the bottom provides support and eliminates the eccentric force of the workpiece to ensure the working accuracy of the turntable 1; outside the top of the turntable 1 A transmission ring gear 2 is arranged on the circumferential surface, and a hydraulic motor suspension device is respectively arranged on the turntable base 4 and the left and right sides of the turntable 1, and the first hydraul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com