Lathe tool

A lathe tool and tool holder technology, applied in the field of lathe tools, can solve the problems of unusable obtuse angle parts and low utilization rate of blades, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

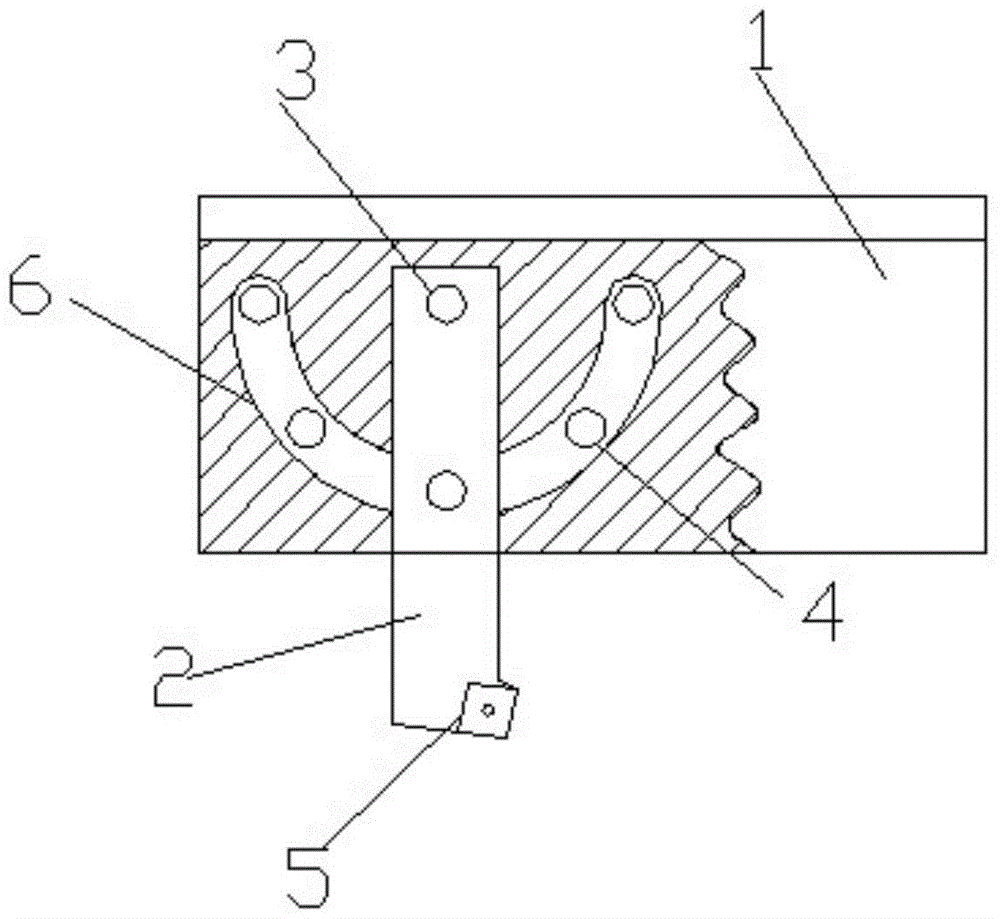

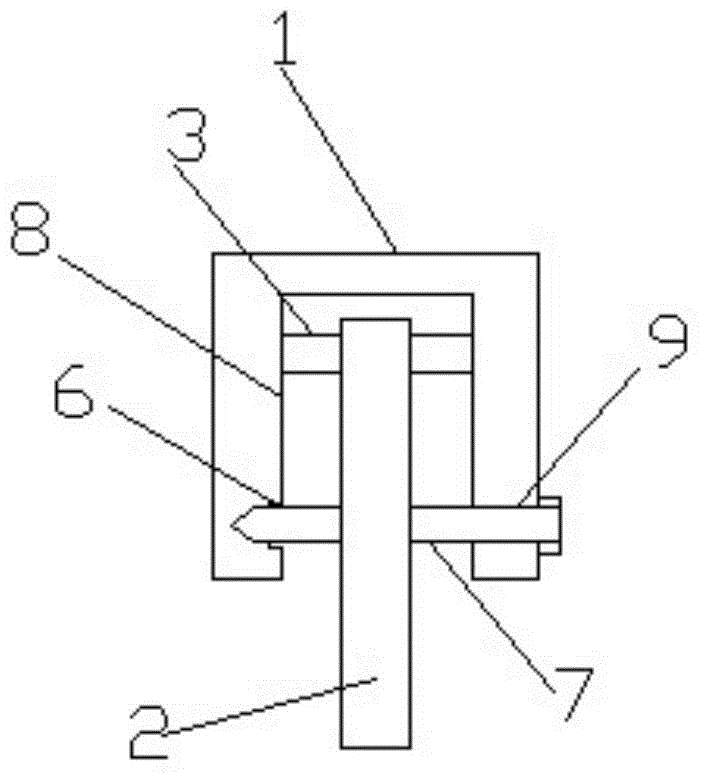

[0013] Such as figure 1 with figure 2 As shown, a lathe tool includes a tool bar 1, a tool holder 2, and a blade 5. The tool bar 1 is provided with a square groove 8, and the square groove 8 is provided with a screw 3 and a bolt 7, and the tool holder 2 is placed in the square groove 8. Inside and connected with the screw rod 3 and the bolt 7, the screw rod 3 is hinged with the knife rod 1 on both sides, and the inner wall of the knife rod 1 on one side of the square groove 8 is provided with an arc-shaped groove 6, and there are several arc-shaped grooves 6 The limit threaded hole 4 that is compatible with the bolt 7 is provided with several positioning holes 9 corresponding to the limit threaded hole 4 on the other side of the knife rod 1, and the bolt 7 passes through the positioning hole 9, the limit screw hole 4 and the knife The rods 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com