An electric motor bed loading and unloading manipulator

A motor and manipulator technology, applied in metal processing and other directions, can solve the problems of high price and lack of integrated design of machine tools

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

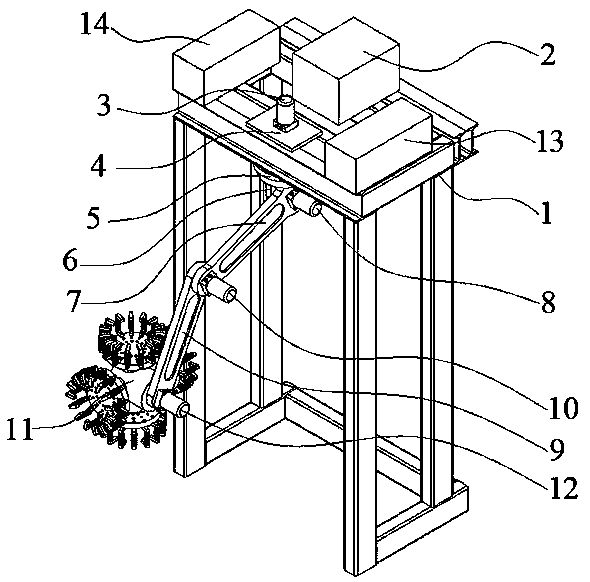

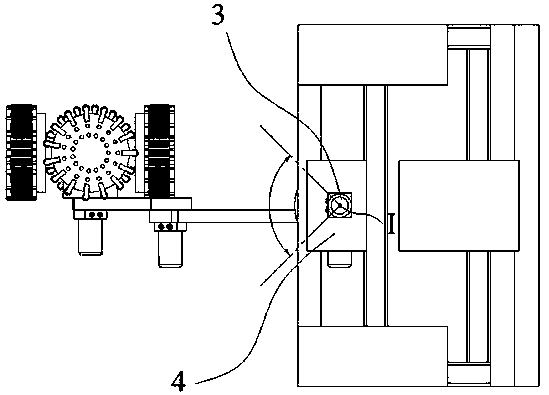

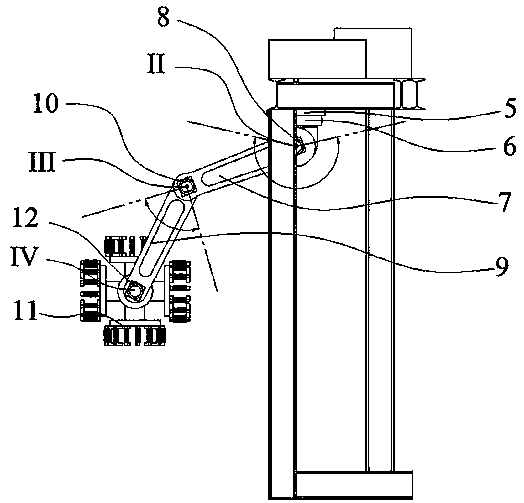

[0036] On the one hand, in order to save energy and reduce costs, the number of driving actuators should be reduced as much as possible, and the concept of "reduced driving components, simple structure, and complete functions" should be adhered to; on the other hand, in practical applications, it is required to be suitable for various working conditions. The invention proposes a motor bed loading and unloading manipulator, which can be installed and used with various machine tools such as horizontal lathes and vertical lathes. Its structure is simple, easy to control, with few degrees of freedom and few driving actuators. It only requires the silo transmission mechanism to send the blanks to the working space of the manipulator, and then the loading and unloading operations on the machine tool can be completed. The manipulator can grasp the blanks and finished parts at the same time, thus improving the work efficiency and further reducing the requirements for the silo conveyor ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com