Archimedes spiral stripe lapping disc for ultra-precision lapping processing

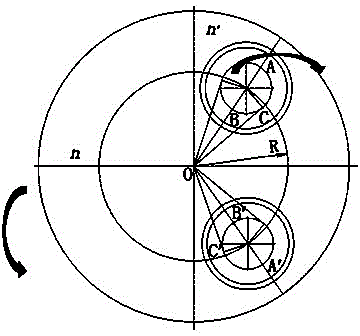

An Archimedes screw and grinding technology, applied in the direction of grinding tools, etc., can solve the problems of poor stability and low work efficiency, and achieve the effect of increasing the probability of abrasive particle damage, high work efficiency, and low precision requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

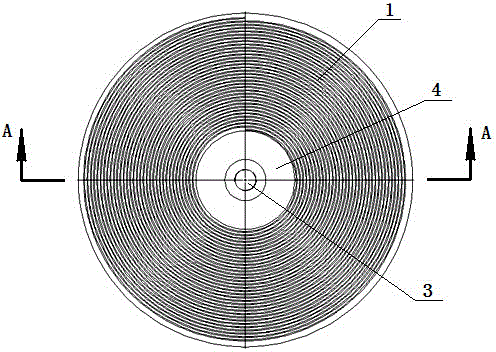

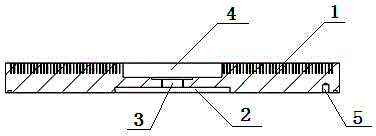

[0019] The Archimedes spiral grinding disc of the present embodiment is characterized in that the upper surface of the grinding disc is provided with an Archimedes spiral 1, and the width of the spiral groove in the Archimedes spiral is 4 mm, and the depth is 5 mm, so that the grinding disc During the working process, the force-bearing area and contact surface with the workpiece are in an ideal state. The center of the upper surface of the grinding disc is also equipped with an abrasive and impurity collection tank 4 to collect abrasives and impurities in time to prevent abrasives and impurities from being excluded from causing damage to the surface of the workpiece. Scratches increase, affecting the precision of finished products. The collection tank has an inner diameter of 160.0mm and a depth of 30.0mm.

[0020] There is a positioning hole 2 on the back of the grinding disc. The location and size of the positioning hole match the size of the boss on the grinding machine. Th...

Embodiment 2

[0042] The Archimedes spiral grinding disc of the present embodiment is characterized in that the upper surface of the grinding disc is provided with the spiral groove in the Archimedes spiral. The force-bearing area and contact surface are in an ideal state, and the center of the upper surface of the grinding disc is also equipped with an abrasive and impurity collection tank 4 to collect abrasives and impurities in time to prevent abrasives and impurities from being excluded, resulting in increased scratches on the workpiece surface and affecting the accuracy of the finished product . The collection tank has an inner diameter of 150.0mm and a depth of 30.0mm.

[0043] There is a positioning hole 2 on the back of the grinding disc. The location and size of the positioning hole match the size of the boss on the grinding machine. The positioning hole is used to fix the grinding disc and the grinding machine. There is a through hole 3 in the center of the grinding disc. , the i...

Embodiment 3

[0045]In the Archimedes spiral pattern grinding disc of this embodiment, the width of the spiral groove in the Archimedes spiral pattern on the upper surface of the grinding disc is 5 mm, the depth is 15 mm, and the center of the upper surface of the grinding disc is also provided with an abrasive and impurity collection groove 4 , in order to collect abrasives and impurities in time to prevent abrasives and impurities from being eliminated, resulting in increased scratches on the surface of the workpiece and affecting the accuracy of the finished product. The collection tank has an inner diameter of 170.0mm and a depth of 30.0mm.

[0046] There is a positioning hole 2 on the back of the grinding disc. The location and size of the positioning hole match the size of the boss on the grinding machine. The positioning hole is used to fix the grinding disc and the grinding machine. There is a through hole 3 in the center of the grinding disc. , the inner wall of the through hole is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com