Mold core that can be shifted left and right

A mold core and mold technology, applied in the field of molds, can solve the problems of high adjustment cost and inconvenient operation, and achieve the effects of simple structure, convenient adjustment, and saving adjustment and maintenance time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

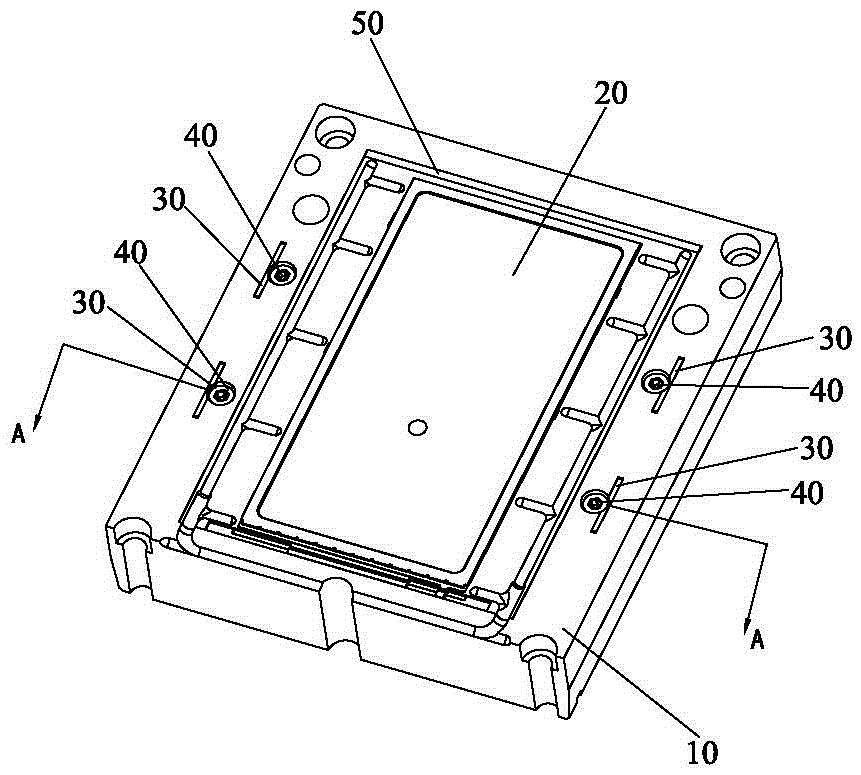

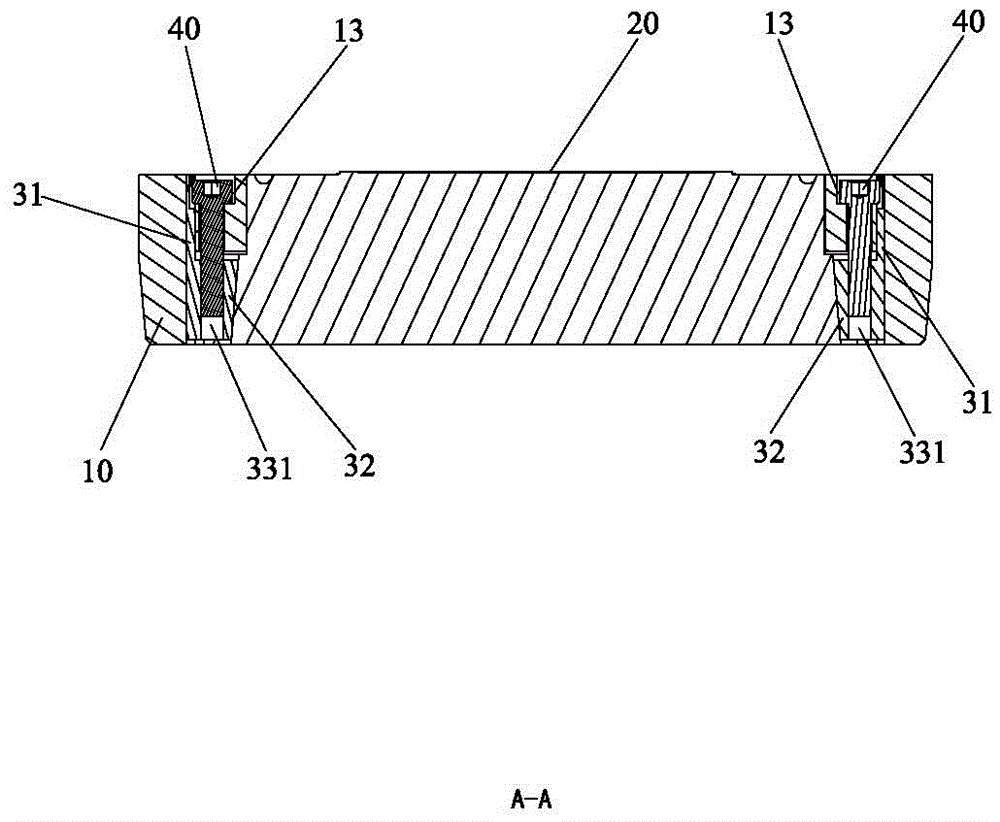

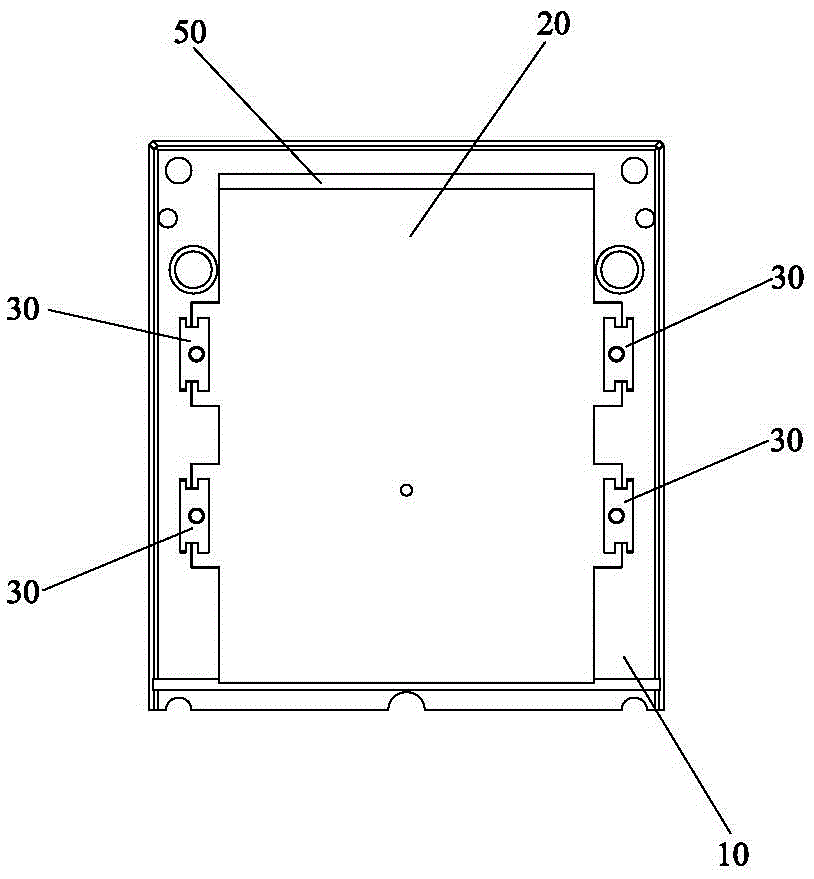

[0032] The present invention as Figure 1 to Figure 8 As shown, a mold core that can be shifted left and right includes an outer mold core 10, an inner mold core 20, a plurality of adjustment blocks 30, adjustment screws 40, and an oblique pressure block 50, wherein:

[0033] The outer mold core 10 has a mold cavity 11, and two embedding parts 12 are respectively arranged on both sides of the inner wall of the mold cavity 11, and the embedding parts 12 include a vertical embedding groove 121 and a transverse accommodating groove 122. The upper and lower ends of the vertical slot 121 run through the upper and lower walls of the outer mold core 10 respectively. It communicates with the aforementioned mold cavity 11 , and the transverse accommodation groove 122 opens toward the lower end of the outer mold core 10 , and a first threaded hole 13 communicating with the transverse accommodation groove 122 is provided through the side wall of the outer mold core 10 .

[0034] Two obl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com