Vehicle seat sponge, manufacturing method, module and vehicle seat

A car seat and sponge technology, which is applied to vehicle seats, vehicle parts, special positions of vehicles, etc., can solve problems such as single density and hardness of sponges, uncomfortable rides, etc., achieve good support, improve comfort performance, and good plasticity shape effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

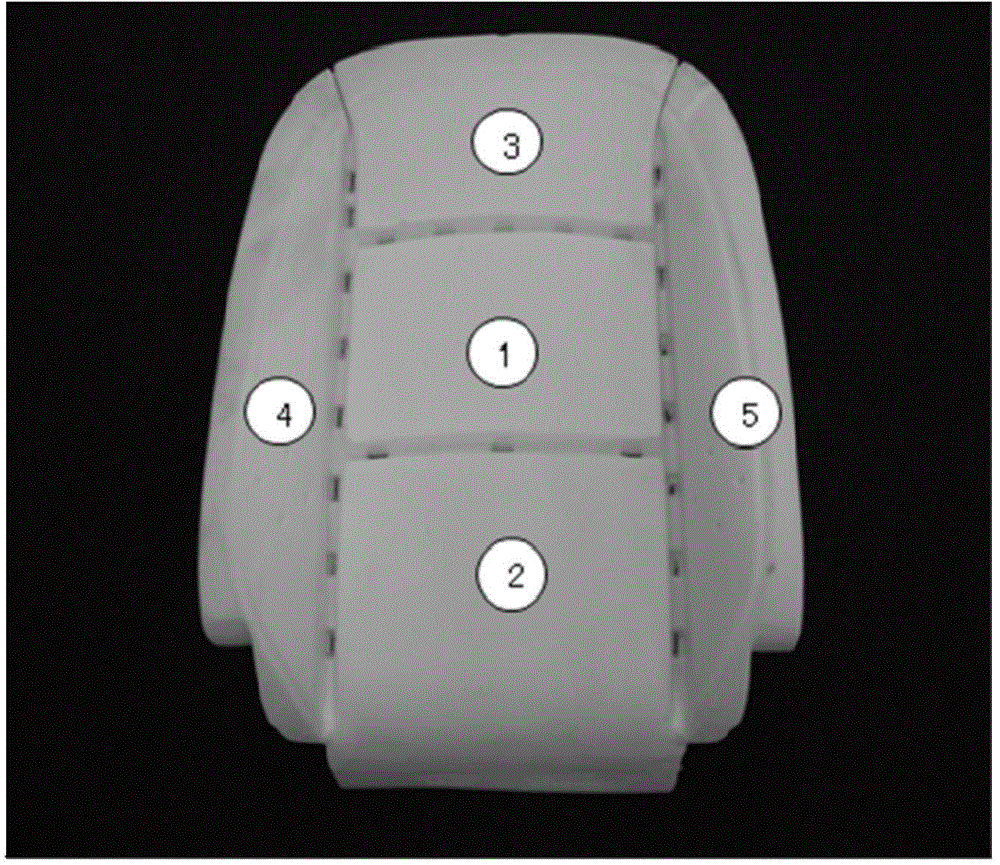

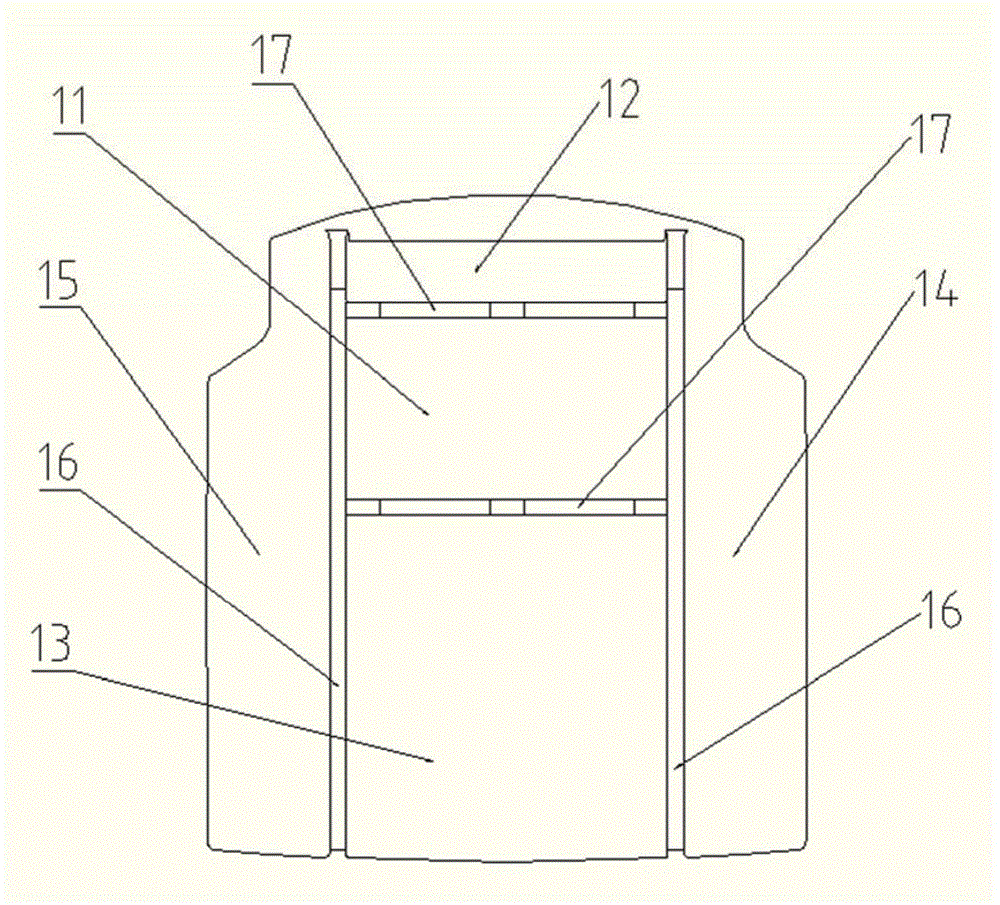

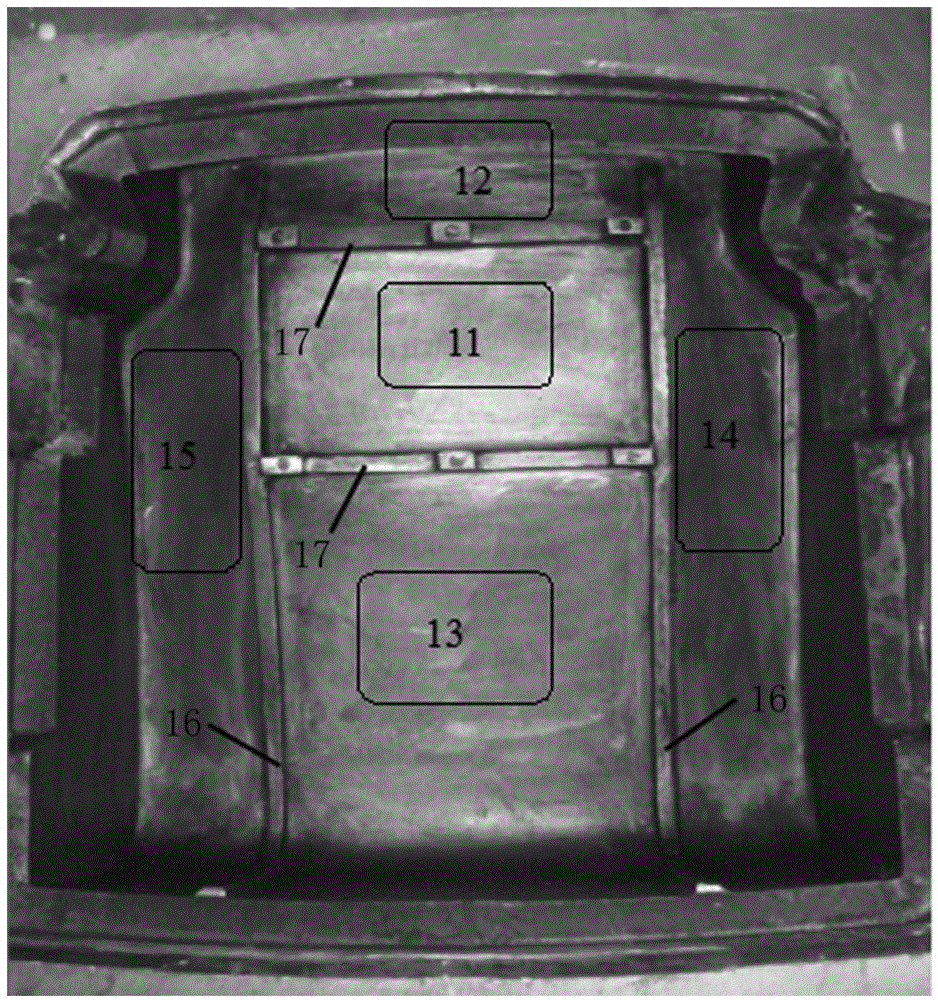

[0061] The car seat sponge of the present embodiment, such as figure 1 As shown, it includes the main functional area, and the left supporting area 4 and the right supporting area 5 are respectively arranged on both sides of the main functional area; the main functional area includes the front area 3, the central area 1 and the rear area 2 in order from front to back; The density of the central zone 1 is 60g / m 3 , 25% indentation hardness is 150N; the density of the front zone 3 is 45g / m 3 , 25% indentation hardness is 190N; the density of left support zone 4, right support zone 5 and rear zone 2 is 40g / m 3 , 25% indentation hardness is 250N.

[0062] The connecting parts of the various partitions in the automobile seat sponge are formed by automatically converging, extruding, and co-foaming the raw materials of the adjacent partitions of the parts during foaming.

[0063] In the car seat sponge of the present embodiment, the central region is made of the following parts by...

Embodiment 2

[0074] The car seat sponge of this embodiment includes a main functional area, and a left support area and a right support area are respectively arranged on both sides of the main functional area; the main functional area includes a front area, a central area and a rear area in sequence from front to back ; The density of the central zone is 65g / m 3 , 25% indentation hardness is 130N; the density of the front area is 55g / m 3 , 25% indentation hardness is 150N; the density of the left support area, right support area and rear area is 50g / m 3 , 25% indentation hardness is 190N.

[0075] The connecting parts of the various partitions in the automobile seat sponge are formed by automatically converging, extruding, and co-foaming the raw materials of the adjacent partitions of the parts during foaming.

[0076] In the car seat sponge of the present embodiment, the central region is made of the following raw materials and isocyanate according to the mass ratio of 100:45 (high-dens...

Embodiment 3

[0087] The car seat sponge of this embodiment includes a main functional area, and a left support area and a right support area are respectively arranged on both sides of the main functional area; the main functional area includes a front area, a central area and a rear area in sequence from front to back ; The density of the central zone is 70g / m 3 , 25% indentation hardness is 110N; the density of the front area is 50g / m 3 , 25% indentation hardness is 170N; the density of the left support area, right support area and rear area is 45g / m 3 , 25% indentation hardness is 220N.

[0088] The connecting parts of the various partitions in the automobile seat sponge are formed by automatically converging, extruding, and co-foaming the raw materials of the adjacent partitions of the parts during foaming.

[0089] In the car seat sponge of the present embodiment, the central region is made of the following raw materials and isocyanate according to the mass ratio of 100:50 (high-dens...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Indentation hardness | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com