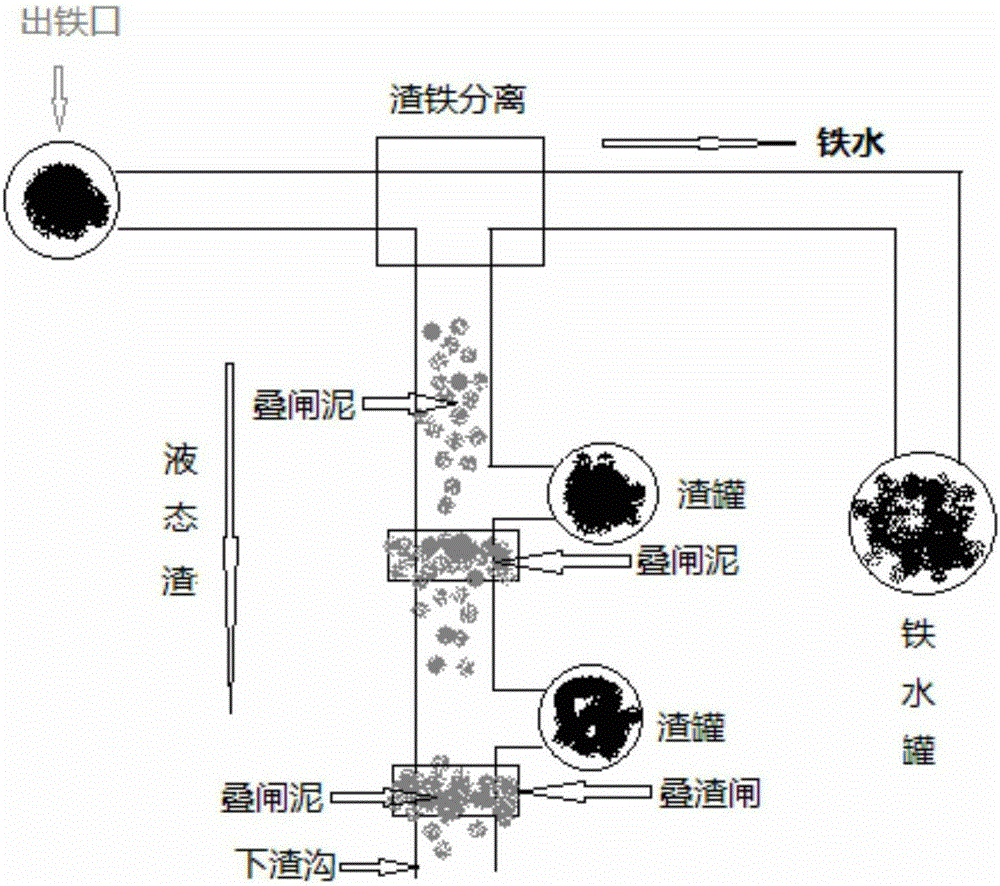

A kind of stacking mud for blast furnace slag ditch and its preparation method and use method

A technology of blast furnace slag and cascading gates, which is applied in the field of refractory mud for blast furnace ironmaking, can solve the problems of high production and use costs, reduce production costs and achieve good application effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Example 1 Preparation and application effect of stacked mud for blast furnace slag ditch of the present invention

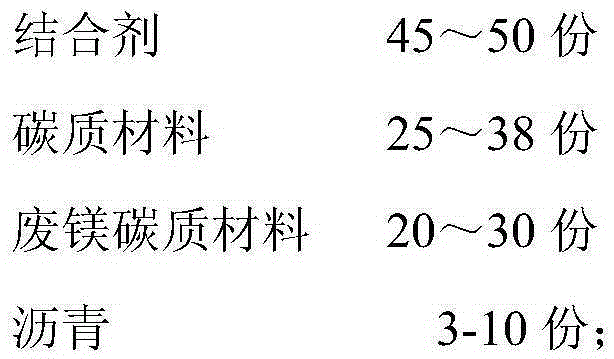

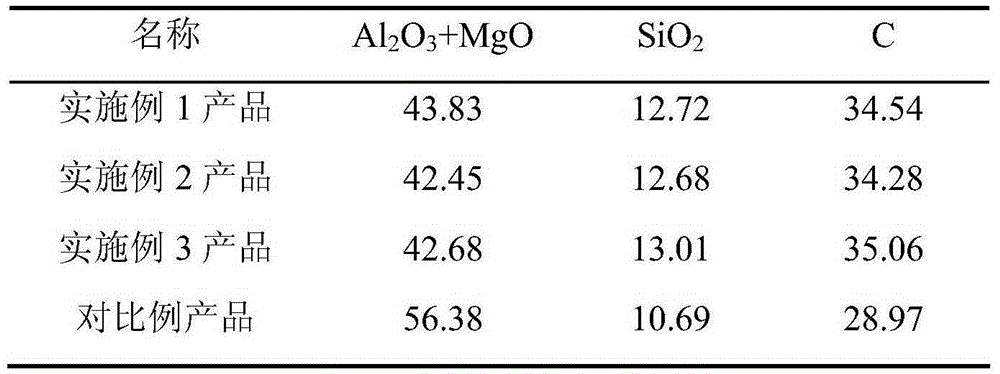

[0026] After weighing 46 parts by weight of binder, 25 parts by weight of coke powder, 23 parts by weight of waste magnesium carbonaceous material, and 6 parts by weight of pitch, the waste magnesium material and coke powder are respectively sent into the mixing mixer Carry out mixing and stirring. After mixing and stirring for 1 minute, add asphalt and binder and continue mixing and stirring for 4 minutes. Finally, add 9% water and stir for 2 minutes, then pack it into bags for later use, and take samples for inspection. See Table 1 for details of the indicators, and see Tables 2 and 3 for details on the effect of using stacked mud for blast furnace slag ditch as a release agent on site.

Embodiment 2

[0027] Example 2 Preparation and application effect of stacked mud for blast furnace slag ditch of the present invention

[0028] After weighing 50 parts by weight of binder, 25 parts by weight of coke powder, 20 parts by weight of waste magnesium carbonaceous material, and 5 parts by weight of pitch, the waste magnesium material and coke powder are respectively sent into the mixing mixer Mix and stir. After mixing and stirring for 1 minute, add asphalt and binder and continue mixing and stirring for 4 minutes. Finally, add 9% water and stir for 2 minutes, then pack it into bags for later use, and take samples for inspection. See Table 1 for details, and see Tables 2 and 3 for details on the effect of using stacked sluice mud for blast furnace slag ditch as a release agent on site.

Embodiment 3

[0029] Example 3 Preparation and application effect of stacked mud for blast furnace slag ditch of the present invention

[0030] After weighing 48 parts by weight of binder, 26 parts by weight of coke powder, 20 parts by weight of waste magnesium carbonaceous material, and 8 parts by weight of pitch, the waste magnesium material and coke powder are respectively sent into the mixing mixer Mix and stir. After mixing and stirring for 1 minute, add asphalt and binder and continue mixing and stirring for 4 minutes. Finally, add 9% water and stir for 2 minutes, then pack it into bags for later use, and take samples for inspection. See Table 1 for details, and see Tables 2 and 3 for details on the effect of using stacked sluice mud for blast furnace slag ditch as a release agent on site.

[0031] Comparative example of stacking mud: 8 parts by weight of asphalt, 26 parts by weight of coke powder, 20 parts by weight of magnesia, and a conventional binder. See Table 1 for the physica...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com