Cell culture plate fixture structure

A technology of cell culture and plate clamping, which is applied to tissue cell/virus culture devices, biochemical instruments, biochemical equipment and methods, etc. It can solve the problems that latex pads cannot perform gas exchange, poor sealing, and cannot be guaranteed. To achieve the effect of avoiding bacterial contamination and cross-contamination, ensuring airtightness, and avoiding pressure injuries

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

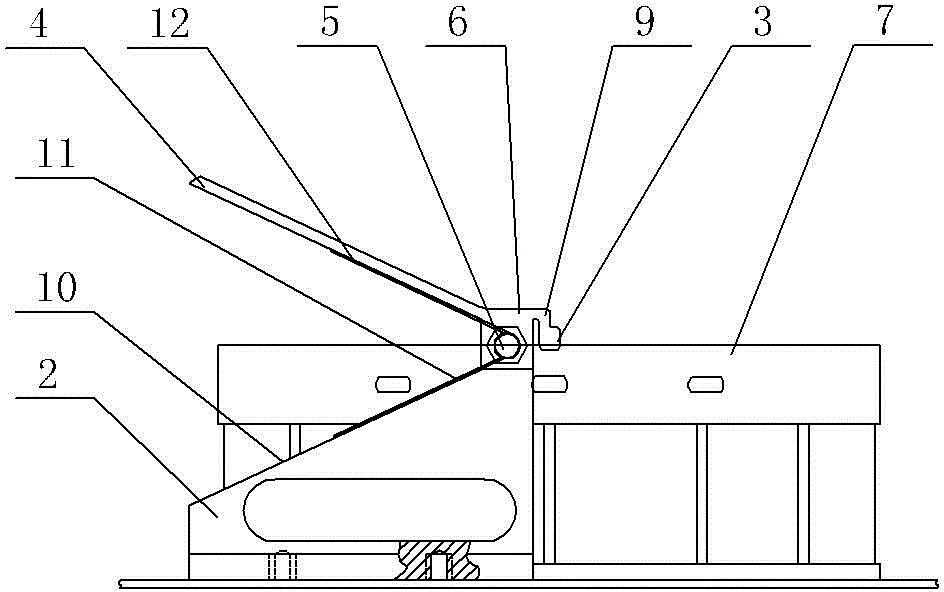

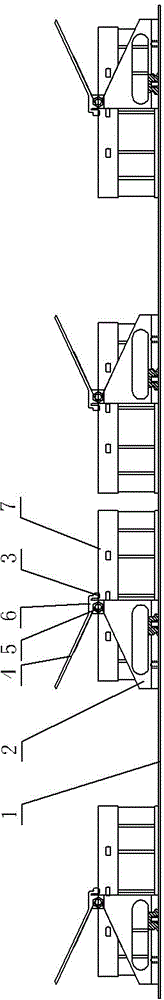

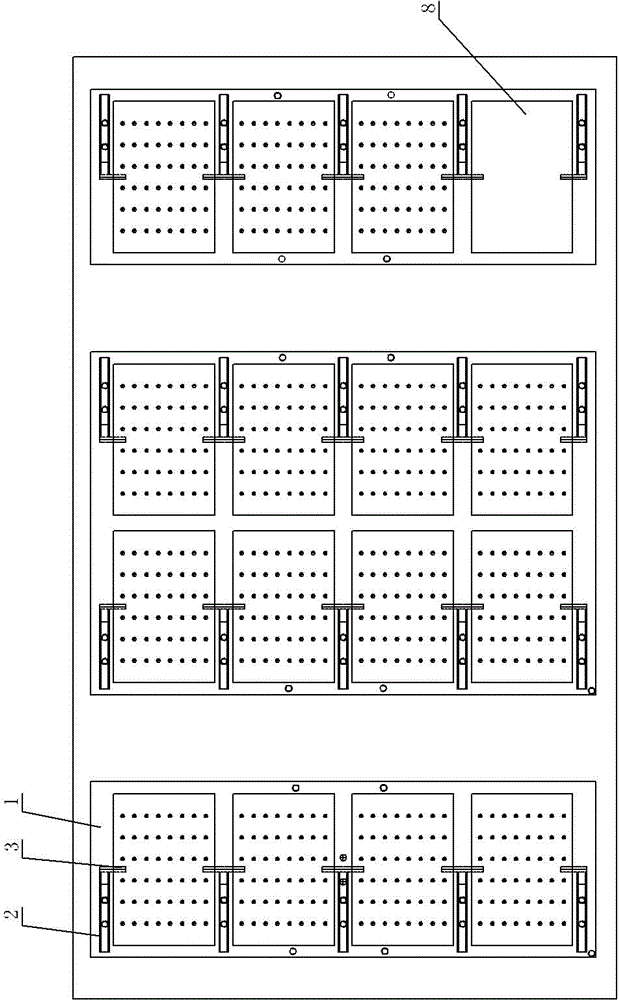

[0014] Such as Figure 1 to Figure 4 As shown, the bottom plate 1 is included, and the bottom plate 1 is provided with a groove 8 matching the cell culture plate 7. The two sides of the groove 8 are symmetrically provided with a support 2, and the upper end of the support 2 is provided with a rotating shaft 5. The pressing bar includes a pressing bar arm 4. And the connection part 6 arranged at one end of the pressure bar arm 4, the connection part 6 is connected on the rotating shaft 5, and the rotating shaft 5 is sleeved with a torsion spring, and the two spring feet of the torsion spring are divided into 12 and 11 respectively against the pressure bar arm 4 The lower end surface of the lower end surface and the upper end surface 10 of the bracket 2, the other side of the connecting part 6 relative to the pressure bar arm 4 is provided with a bead 3, and the bead 3 is arranged in parallel above the groove 8; it also includes a curved elastic connecting rod 9, elastic Bot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com