9Ni low temperature seamless steel pipe with large aperture and production method thereof

A seamless steel pipe and large-diameter technology, applied in the field of large-diameter 9Ni low-temperature seamless steel pipes, can solve the problems of high welding process requirements and high production costs, and achieve the effect of dense and uniform internal structure, excellent low-temperature performance and crack suppression.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

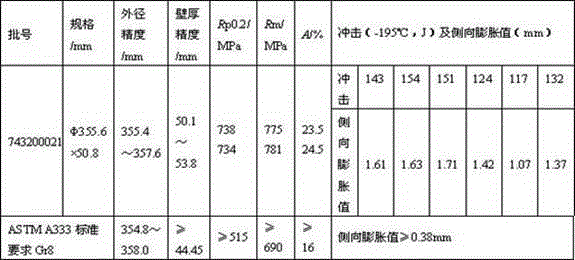

[0023] A large-diameter 9Ni low-temperature seamless steel pipe, the composition of which is in mass %, specifically: C: 0.06, Si: 0.25, Mn: 0.070, P: 0.008, S: 0.0029, Al: 0.05, Mo: 0.08, Ni: 9.03, the rest is Fe and unavoidable impurities.

[0024] The large-diameter 9Ni low-temperature seamless steel pipe is produced by the Pilger rolling process, which includes: tube blank blanking → tube blank center punching → annular furnace heating → Mann piercer piercing → Pilger rolling mill tube → cutting Pilger head → walking furnace heating → sizing machine sizing → heat treatment → straightening → sawing → internal and external surface treatment → manual inspection → ultrasonic eddy current automatic combined flaw detection → manual re-inspection → cleaning, marking, packaging → storage.

[0025] The specific production steps of billet heating, tube rolling and quenching and tempering treatment are as follows:

[0026] A. Billet heating is divided into preheating, heating, and s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com