Method for preparing blocky graphite anode with high density and low resistivity in short process

A block graphite, high-density technology, applied in the direction of manufacturing tools, ceramic molding machines, etc., can solve the problems of increasing the number of dipping and roasting, poor oxidation resistance, low product strength, etc., to reduce the dipping and roasting process, improve density and heat conduction Sexuality and the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

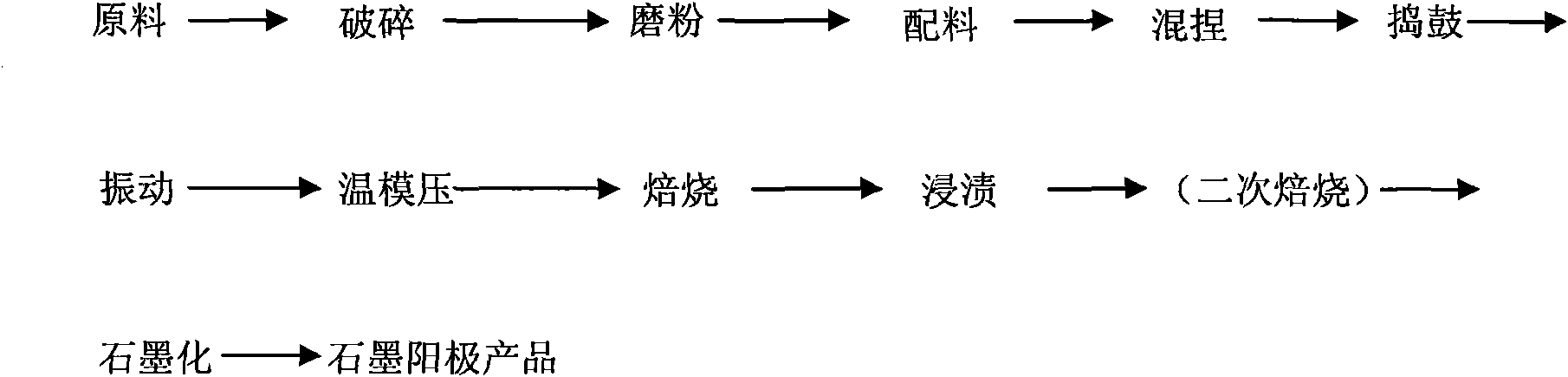

[0035] Please see attached figure 1 , the specification is 2500mm×1500mm×150mm. Make the true density 2.13g / cm 3 , the high-quality needle coke with an ash content of 0.1% is sieved and ultrafinely ground to make four kinds of particles of 2~1mm, 1~0.5mm, 0.5~0.15mm, 0.15~0.076mm and ultrafine powder below 0.076mm Material, so that the purity is above 85%, the weight ratio of the above five particle sizes of needle coke is 2-1mm 125kg, 1-0.5mm 225kg, 0.5-0.15mm 300kg, 0.15-0.076mm 125kg, 0.076mm 225kg, And add 10kg of crushed graphite below 1mm for batching. Dry mix 10kg of crushed graphite and 1000kg of needle coke evenly, and heat to 160±5°C. Then add 214.5kg of modified asphalt with a softening point of 108-110°C, knead in a kneading pot at 160±5°C for 20 minutes, and knead evenly. The mold is preheated to 140°C, the paste is tamped, vibrated, and then warm molded with a pressure of 23.6MPa. Ensure that the bulk density of the pressed product is 1.74±0.02g / cm 3 , when...

Embodiment 2

[0037] The specification is 2500mm×1500mm×150mm. Make the true density 2.13g / cm 3, the high-quality needle coke with an ash content of 0.05% is sieved and ultrafinely ground to make four kinds of particles of 2~1mm, 1~0.5mm, 0.5~0.15mm, 0.15~0.076mm and ultrafine powder below 0.076mm Material, so that its purity is above 85%, the weight ratio of the above five particle sizes of needle coke is 2~1mm 125kg, 1~0.5mm 225kg, 0.5~0.15mm 300kg, 0.15~0.076mm 125kg, 3 , the key temperature zone is raised by 5°C per hour during firing, and the maximum temperature on the surface of the sample is controlled at 1100°C to ensure that the roasted product does not deform or crack, and the bulk density is kept at 1.63±0.02g / cm 3 ; Then impregnate with impregnated pitch, the vacuum degree is 1.5kPa, and the pressurization pressure is 1.2MPa; the surface temperature of the re-roasted sample is 1000°C to ensure that the volume density of the second-baked product reaches 1.74g / cm 3 . After graph...

Embodiment 3

[0039] The specification is 2500mm×1500mm×150mm. Make the true density 2.13g / cm 3 Above, high-quality needle coke with an ash content of 0.05% is sieved and ultrafinely ground to make four kinds of particles of 2~1mm, 1~0.5mm, 0.5~0.15mm, 0.15~0.076mm and ultrafine particles below 0.076mm Powder, so that the purity is above 85%, the weight ratio of the above five particle sizes of needle coke is 2~1mm 125kg, 1~0.5mm 225kg, 0.5~0.15mm 200kg, 0.15~0.076mm 125kg, 3 , the key temperature zone is raised by 5°C per hour during firing, and the maximum temperature on the surface of the sample is controlled at 1100°C to ensure that the roasted product does not deform or crack, and the bulk density is kept at 1.63±0.02g / cm 3 ; then impregnate with impregnated pitch, adopt a vacuum degree of 1.5kPa, and a pressurized pressure of 1.0MPa; re-roast the sample surface temperature at 1000°C to ensure that the volume density of the second-baked product reaches 1.74g / cm 3 . After graphitizati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com