Production method of weft knitting lace fabric

A production method and weft knitting technology, applied in the directions of weft knitting, textiles, papermaking, knitting, etc., can solve the problems of low production efficiency, narrow application field, high fabric cost, and achieve low processing cost, good economic benefits, and soft hand feel. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Embodiment one: a kind of production method of weft knitted lace fabric, its steps are:

[0028] (1) Machine selection: Jintiansuo TNY 12F seamless underwear machine is used for knitting, and the weft knitting CKCAD system independently developed by the Knitting Engineering Research Center of Jiangnan University is used for pattern design and machine control file generation;

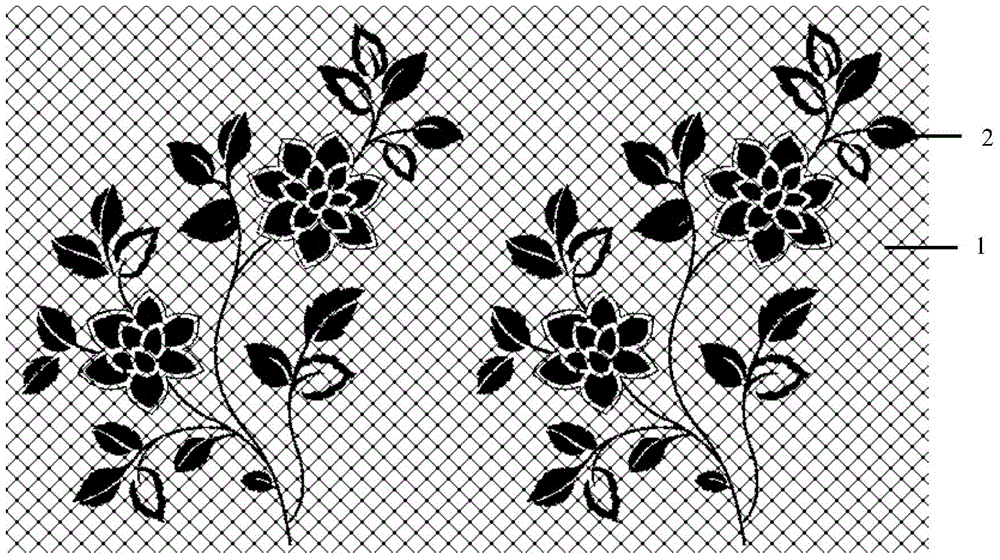

[0029] (2) Flower pattern design: select a picture of a flower pattern, save it in .bmp format, import it into the weft knitting CKCAD system, process the pattern and outline of the picture, remove variegated colors, and divide the pattern into Pattern outline area 2 and non-pattern outline area 1, on the pattern outline area 2, lay a thick tissue consisting of a 4-way continuous non-woven pleat tissue; non-pattern outline area 1 lays intervals 18 as required A variable mesh structure composed of longitudinal pleats. Fill with different colors in areas where different tissues need to be laid;

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com