Lasso plant

A plant and steel strand technology, applied in the field of plant construction, can solve the problems of complex installation process, long construction period, high foundation requirements, etc., and achieve the effect of good seismic performance, low cost of plant, and fast construction speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

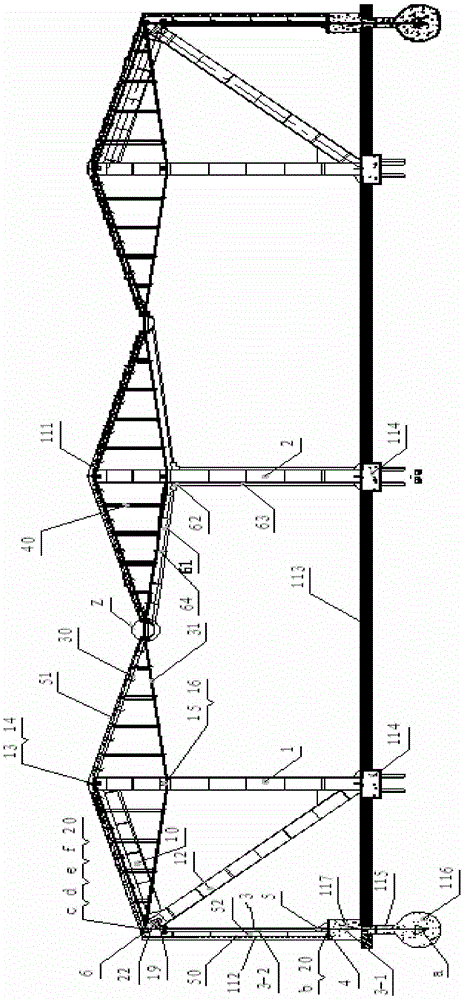

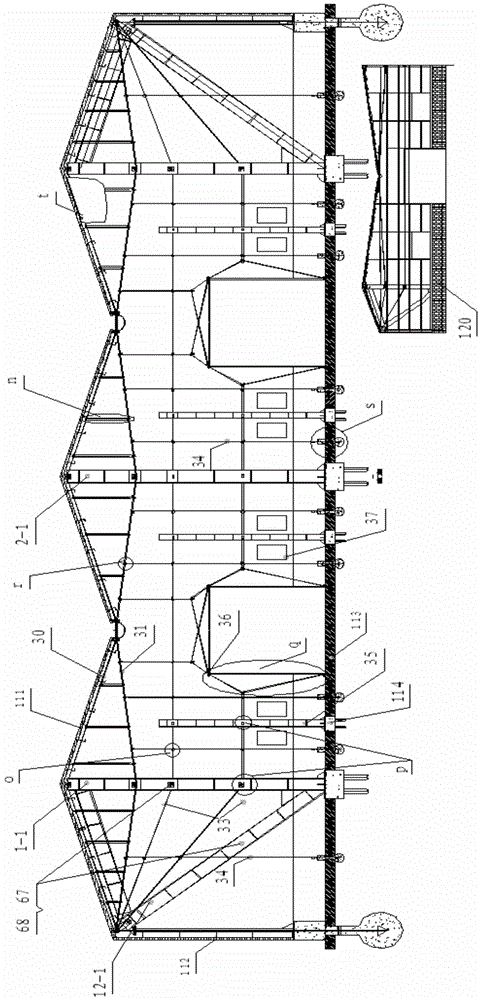

[0045] In order to better understand the present invention, the framework structure and specific implementation methods of the present invention will be explained in detail below in conjunction with the accompanying drawings.

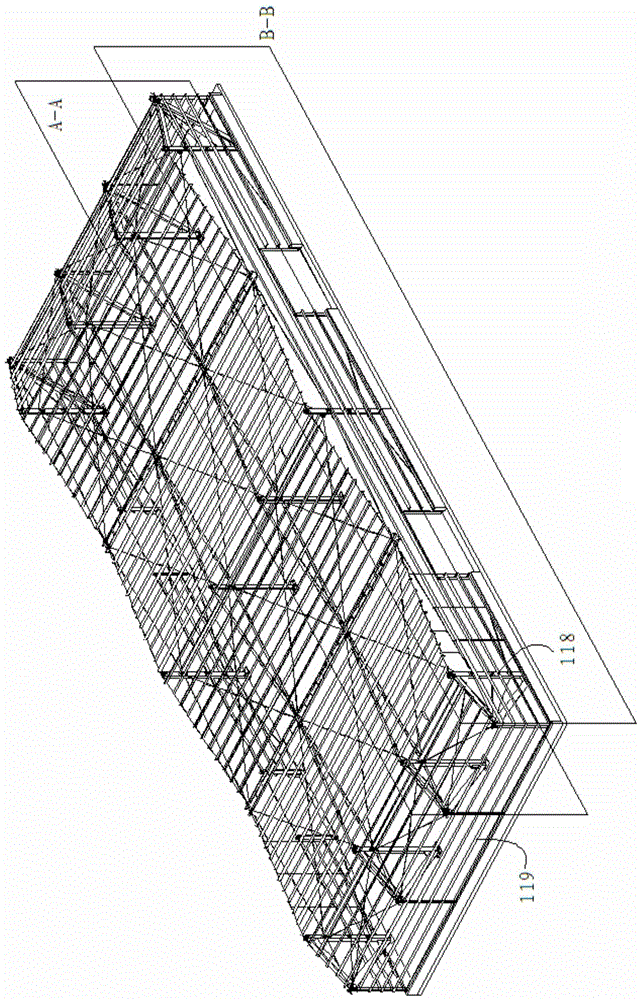

[0046] For the convenience of introducing this technical solution, the direction of two adjacent span-end uprights is set as longitudinal, and the direction of span-end uprights and mid-span uprights is set as transverse. combine Figure 1 to Figure 19 , a cable factory building, comprising a column and a roof cover plate on the top, the column is connected to a column base 114 on the ground, the upper part of the column is provided with a roof steel strand 30, a load-sharing and balanced steel strand 31, a roof anti-corrosion Steel strands 32 for lateral movement, steel strands 7 for resisting lateral movement on the wall, and the roof cover plate is connected to the steel strands 30 of the roof through the support structure at the lower part, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com