High-strength and anti-aging brake cable

An anti-aging and brake line technology, applied in the field of vehicle brake system and brake line, can solve the problems of affecting driving safety, failure of the brake system, easy wear and tear of the end joint of the brake line, etc., to ensure driving safety and protect the effect of wear and tear.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

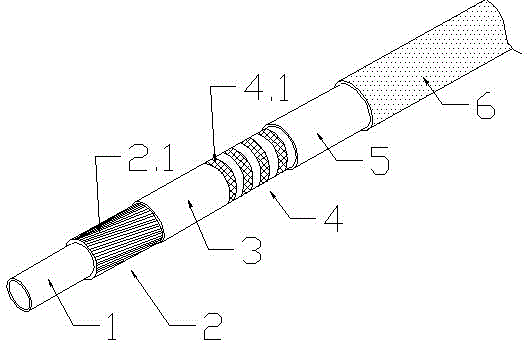

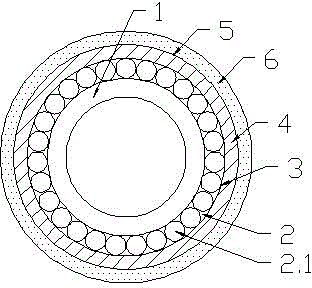

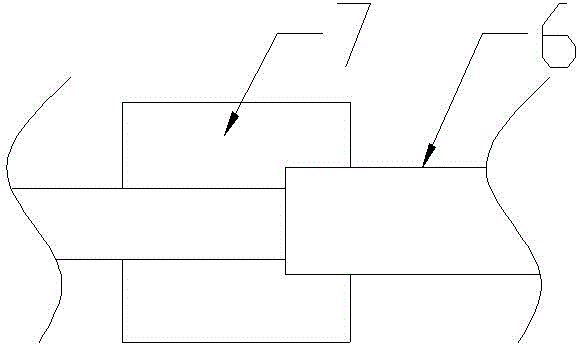

[0024] see Figure 1-3 , the present invention relates to a high-strength aging-resistant brake line, comprising an inner tube 1, a steel wire is arranged inside the inner tube 1, and the outer side of the inner tube 1 is sequentially coated with a tubular layer 2, a first protective layer 3, a strengthening layer 4, The second protective layer 5 and the surface protective layer 6 .

[0025] The inner tube 1 includes the inner tube 1, which can be made of flexible plastic materials such as PP, PE, polyvinyl difluoride (PVDF-commonly known as Teflon), nylon, etc., and its outer side is made of carbon steel, stainless steel, aluminum and aluminum alloy The metal wire body 2.1 made of metal materials such as metal materials is circularly arranged on the surface of the inner tube 1 to form a tubular layer 2, and the tubular layer 2 is covered with a first protective layer 3, and the first protective layer 3 makes the metal wire body 2.1 protected. Layer 3 restraint without poppin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com