Heat insulation structure and heat insulation method of polyethylene gas pipeline

A gas pipeline, heat preservation and heat insulation technology, applied in the direction of pipeline protection, heat preservation, pipeline protection through heat insulation, etc., can solve the problems of small space, difficult to ensure the horizontal clear distance, damage to the integrity of the pipeline system, etc., to achieve convenient splicing and disassembly , Conducive to the effect of maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

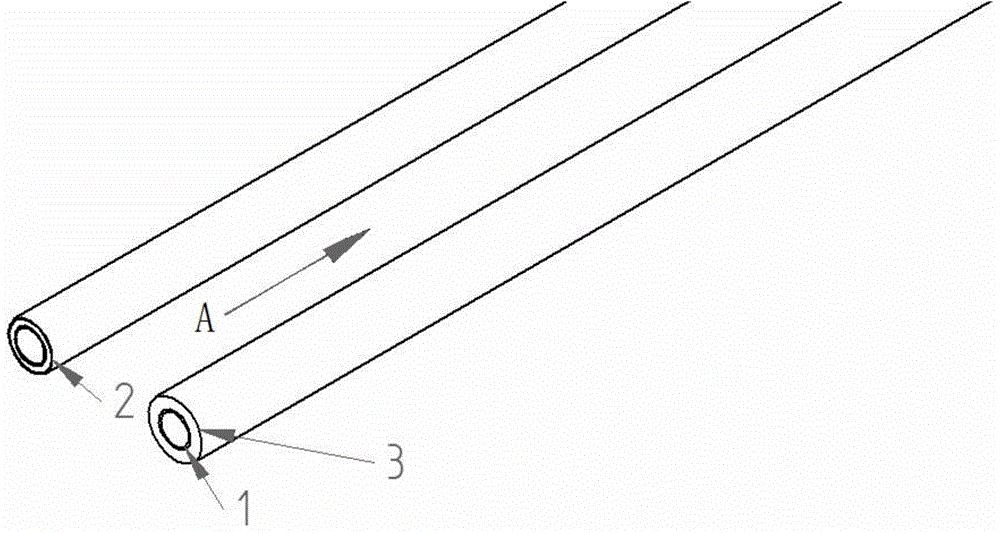

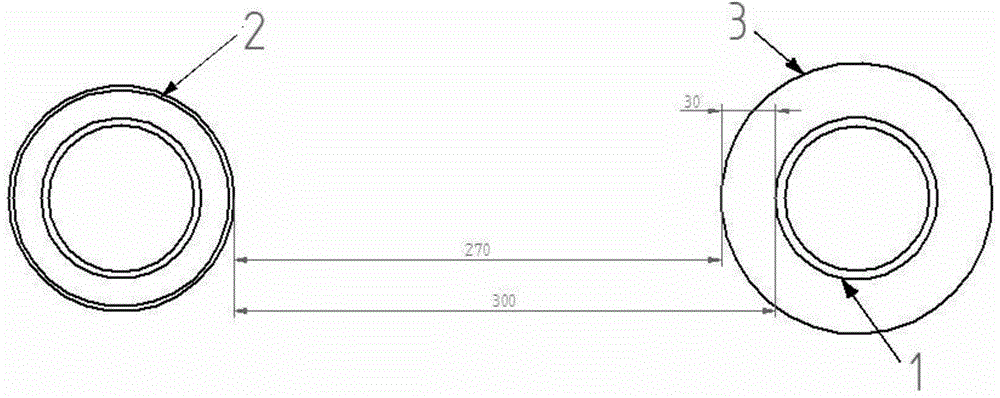

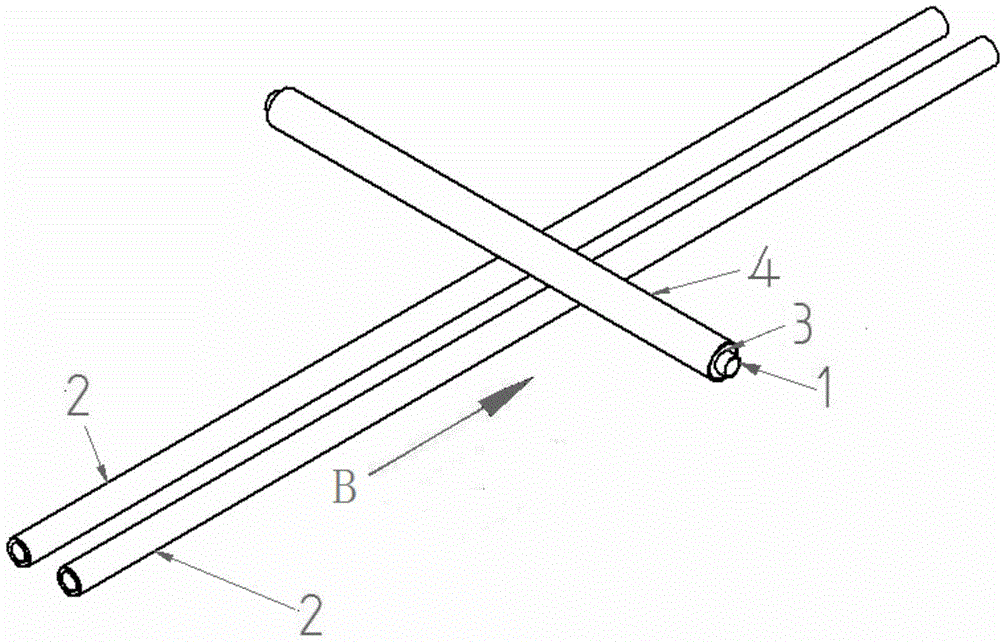

[0044] refer to Figure 1a , Figure 1b , Figure 2a and Figure 2b As shown, the main innovation of the thermal insulation structure and method of the polyethylene gas pipeline of the present invention is that when the polyethylene gas pipeline for transporting gas medium is arranged in an actual project, the polyethylene gas pipeline 1 crosses or parallels with the existing thermal pipeline 2 If the laying cannot meet the minimum horizontal or vertical clearance between the underground polyethylene gas pipeline and the thermal pipeline stipulated in CJJ 63-2008 "Technical Regulations for Polyethylene Gas Pipeline Engineering", the polyethylene gas pipeline 1 body Go up and set insulation tube shell 3 (generally adopt rigid polyurethane foam to make).

[0045] The polyurethane rigid foam insulation shell 3 is preferably a polyurethane rigid foam with a closed-cell structure and a thermal conductivity (at 50°C) of less than or equal to 0.033W / (m·K), which can play a role in ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap