Pulse dust collection device

A technology of pulse dust removal and pulse generation, which is used in the removal of solid residues, combustion products treatment, combustion methods, etc., can solve the problems of frequent replacement, poor ignition efficiency, weak explosion-proof ability, etc., to improve equipment stability, improve The effect of ignition efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

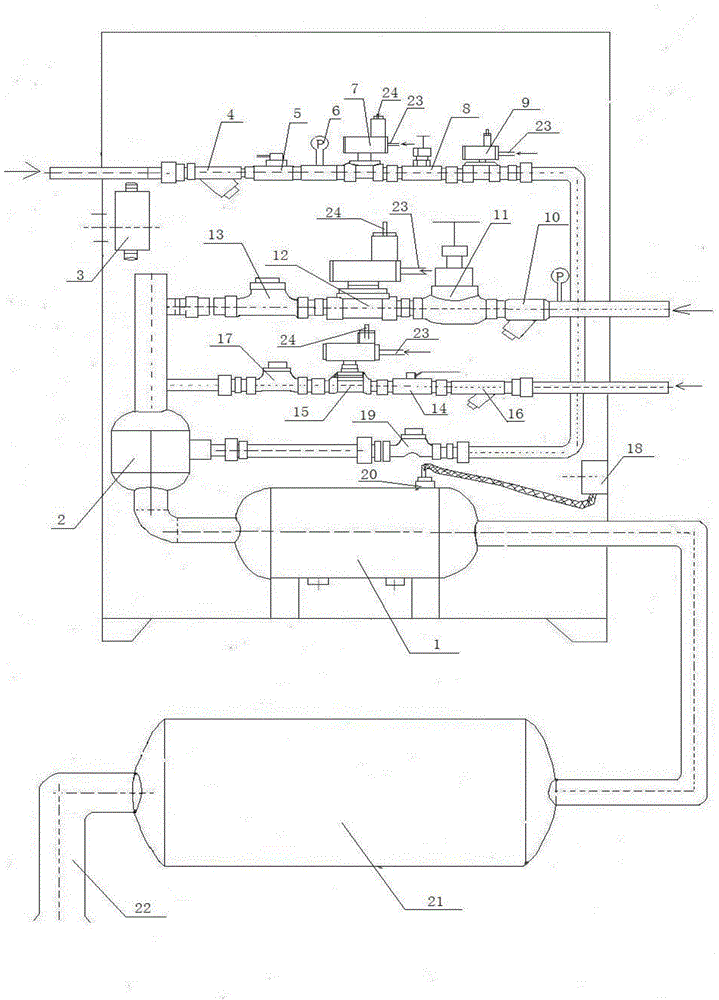

[0020] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

[0021] like figure 1 As shown, a pulse dust removal device includes a gas pipeline, a working air pipeline, a purge air pipeline and a pulse generating pipeline, and the pulse generating pipeline includes a first connecting pipe, a mixing tank 2, a second connecting pipe in sequence Pipe, ignition tank 1, third connecting pipe, pulse tank 21 and pulse nozzle 22, the gas pipeline is connected to the mixing tank 2 and can be communicated through a switch; the working air pipeline and purge air pipeline They are respectively connected to the pipe wall of the first connecting pipe, and can be switched and communicated by a changeover switch. A high-energy igniter 18 is also included, and the high-energy igniter 18 is c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com