A 10kv cable distributed optical fiber temperature measurement method

A distributed optical fiber and cable technology, applied in thermometers, measuring devices, measuring heat and other directions, can solve the problems of endangering the safe operation of cables, difficulty in accurately determining the current carrying capacity of 10kV cables in multi-circuit intensive laying, and cable waste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

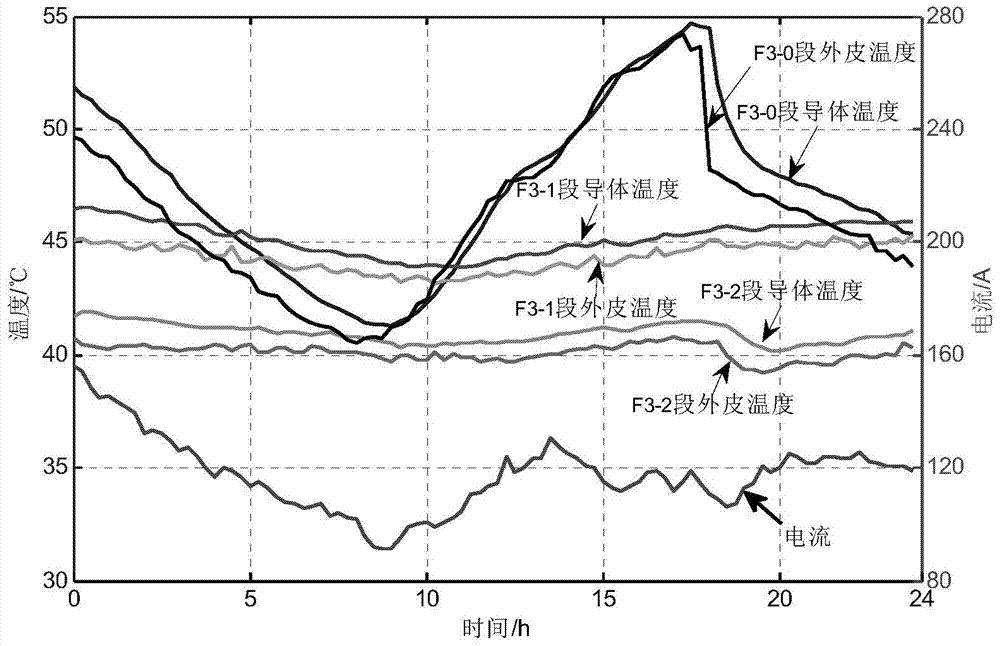

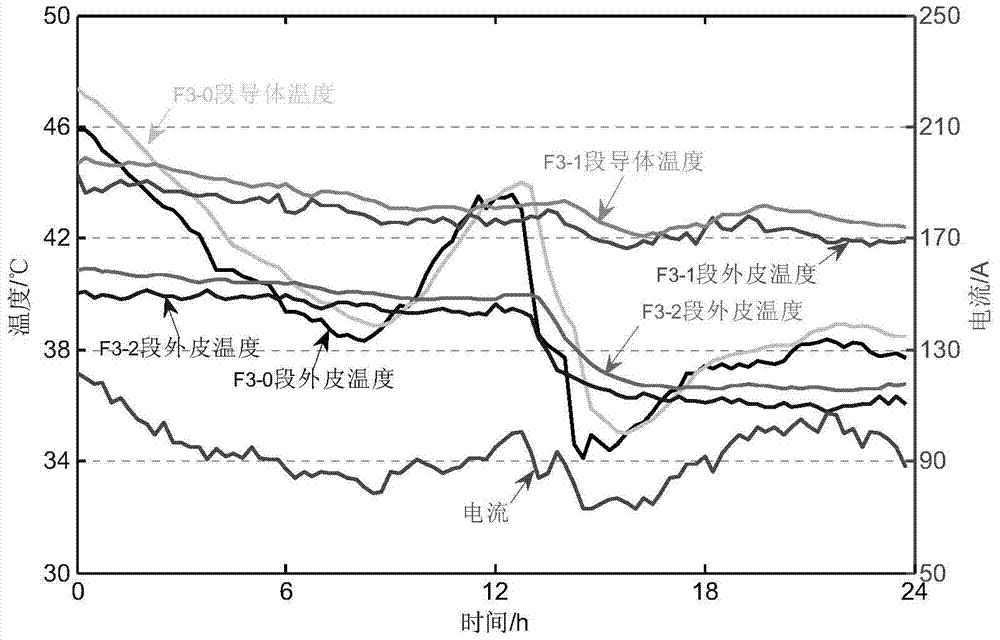

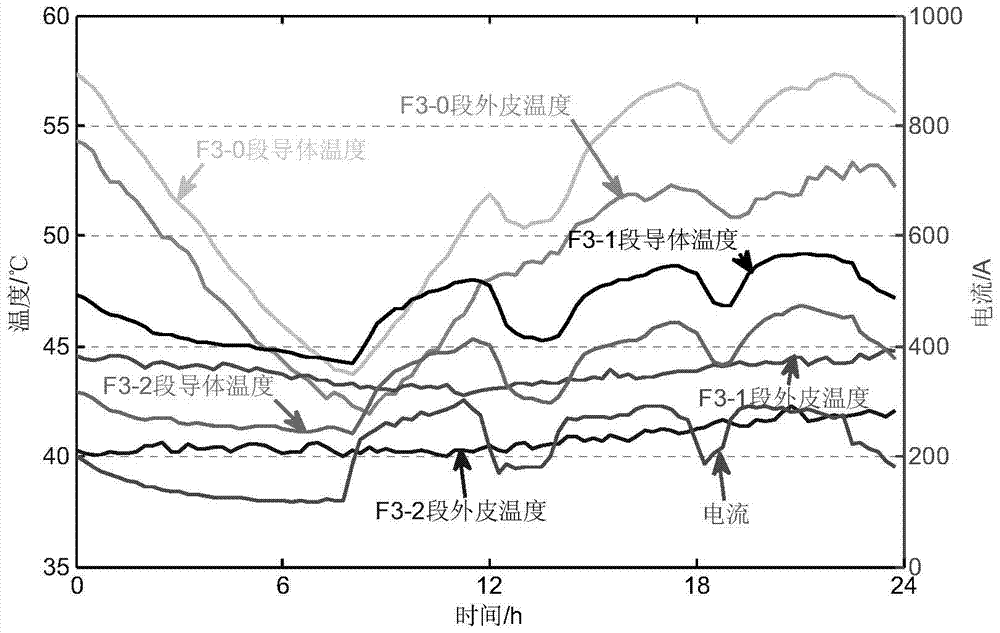

[0016] The Lingbo substation is selected as the test object, which is a 10kV substation outgoing cable.

[0017] At the 10kV cable laying site, first use a pipe threader to thread the pipe, lay the 10kV cable in the pipe, and then use a flushing vehicle to flush the mud in the pipe. The distributed optical fiber temperature measurement system used in this embodiment is a distributed optical fiber temperature measurement system (model: ZD-2) produced by Ningbo Zhendong Optoelectronics Co., Ltd. The distributed optical fiber temperature measurement system includes an optical fiber thermometer and a temperature sensor The optical fiber and the optical fiber thermometer are installed in the duty room of the power station, equipped with 220V power supply, and the temperature-sensing optical fiber is led out from the duty room, and the temperature-sensing optical fiber is penetrated into the tube. The pipe is guided to the exit of the second working well, then turned back, and penet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com