Optical lens

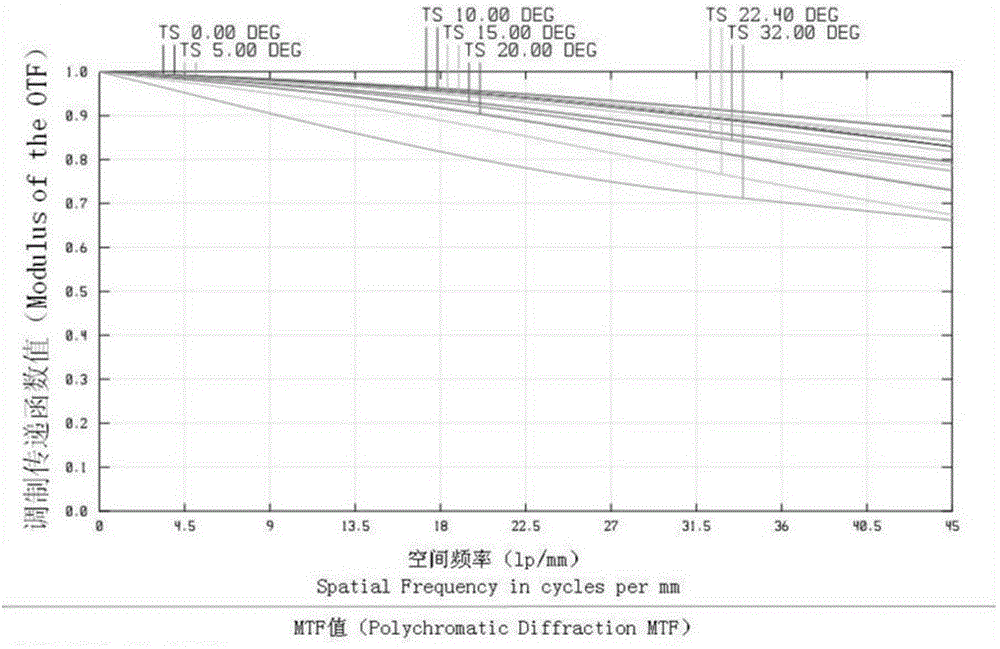

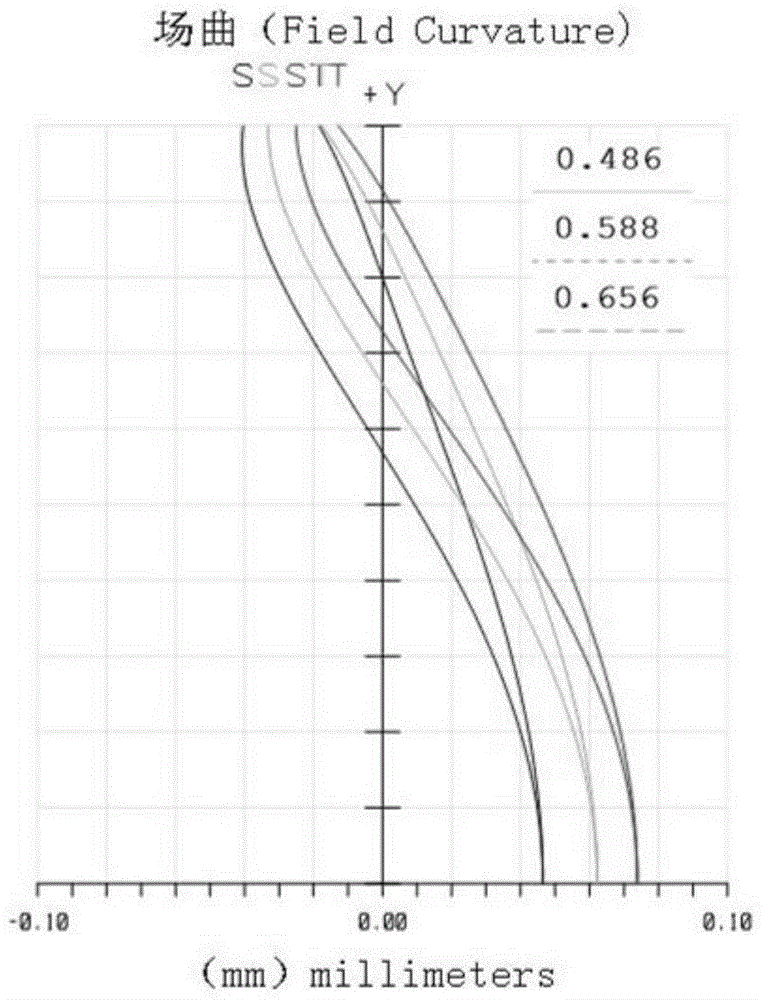

An optical lens and lens technology, applied in the field of optical lens, to achieve the effects of small distortion, high light-passing performance, and aberration correction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

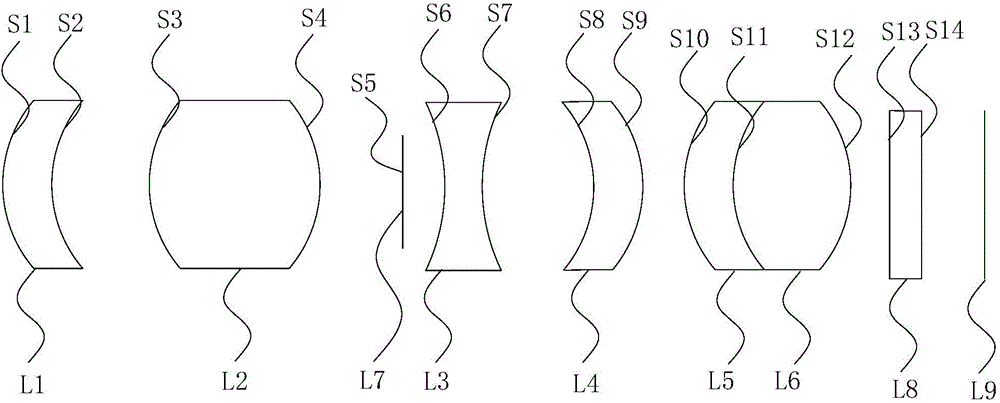

[0050] figure 1 It is a structural schematic diagram of an optical lens provided in a specific embodiment of the present invention. Such as figure 1 As shown, a kind of optical lens of the present invention, from the object side to the image side, includes: a front lens group with positive refractive power, a diaphragm element L7, a rear lens group with positive refractive power, and a color filter L8, and imaging surface L9;

[0051] Wherein, the front lens group includes in sequence from the object side to the image side: a first lens L1 and a second lens L2, and the first lens L1 is a crescent-shaped lens with a negative refractive power and a concave surface facing the image side, so The second lens L2 is a biconvex lens with positive refractive power; the rear lens group includes in sequence from the object side to the image side: the third lens L3, the fourth lens L4, the fifth lens L5 and the sixth lens L6, so The third lens L3 is a biconcave lens with negative refra...

Embodiment 2

[0087] Embodiment 2: It should be noted that the difference between this embodiment and Embodiment 1 lies in that the structure of the cemented lens in the rear lens group in this embodiment is different.

[0088] Figure 5 It is a structural schematic diagram of another optical lens provided in the specific embodiment of the present invention. Such as Figure 5 As shown, a kind of optical lens of the present invention, from the object side to the image side, includes: a front lens group with positive refractive power, a diaphragm element L7, a rear lens group with positive refractive power, and a color filter L8, and imaging surface L9;

[0089] Wherein, the front lens group includes in sequence from the object side to the image side: a first lens L1 and a second lens L2, and the first lens L1 is a crescent-shaped lens with a negative refractive power and a concave surface facing the image side, so The second lens L2 is a biconvex lens with positive refractive power; the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com