Method for simulating troubleshooting training of complex electrical system

A technology of electrical system and simulation method, applied in the field of electrical system, can solve the problems of large hardware cost, increase of fault problem, easy expansion of fault, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

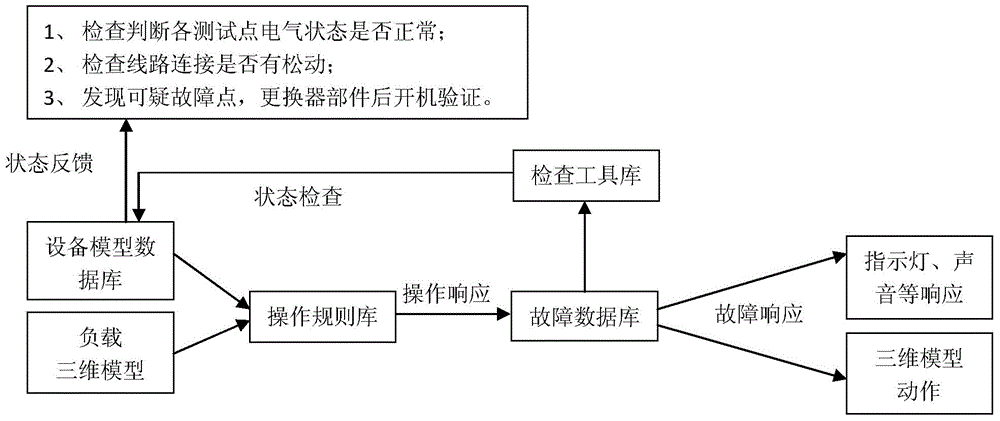

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] The first embodiment of the present invention: a certain type of automobile startup abnormal fault simulation

[0020] After the car is started, due to some electrical faults, some indicator lights or gauges will cause abnormal response conditions that are not correctly indicated. At this time, maintenance personnel are required to troubleshoot them.

[0021] The specific simulation method is:

[0022] Step 1: Select the fault type

[0023] Through the man-machine interface of the training software, select the simulated fault type "abnormal startup fault" (including fault parameters).

[0024] Step 2: Fault simulation and troubleshooting

[0025] (1) According to the fault type, get the trigger timing of the fault, the phenomenon at the time of the fault, the electrical characteristics and the fault location and other parameters;

[0026] (2) According to the fault parameters, during the start-up operation of the electrical system, the fault indication and electrical status and oth...

Embodiment 2

[0028] The second embodiment of the present invention: the simulation of a certain equipment operation jitter fault

[0029] During the working process of CNC machine tools, some electrical faults may cause abnormal response of equipment jitter. At this time, maintenance personnel are required to troubleshoot.

[0030] The specific simulation method is:

[0031] Step 1: Select the fault type

[0032] Through the man-machine interface of the training software, select the simulated fault type "running jitter fault" (including fault parameters).

[0033] Step 2: Fault simulation and troubleshooting

[0034] (1) According to the fault type, get the trigger timing of the fault, the phenomenon at the time of the fault, electrical characteristics and the fault location and other parameters;

[0035] (2) According to the fault parameters, after the electrical system is started, the output of the three-dimensional scene of the jitter of the equipment, other fault indications and electrical status ...

Embodiment 3

[0037] The third embodiment of the present invention: a large printing machine cannot start the fault simulation

[0038] During the start-up process of the printing press, some electrical faults may cause the equipment to fail to rotate abnormally. At this time, maintenance personnel are required to troubleshoot.

[0039] The specific simulation method is:

[0040] Step 1: Select the fault type

[0041] Through the man-machine interface of the training software, select the simulated fault type "Cannot rotate fault" (including fault parameters).

[0042] Step 2: Fault simulation and troubleshooting

[0043] (1) According to the fault type, get the trigger timing of the fault, the phenomenon at the time of the fault, electrical characteristics and the fault location and other parameters;

[0044] (2) According to the fault parameters, during the starting operation of the electrical system, the fault indication and electrical characteristic data and other fault simulation data are gradually...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com