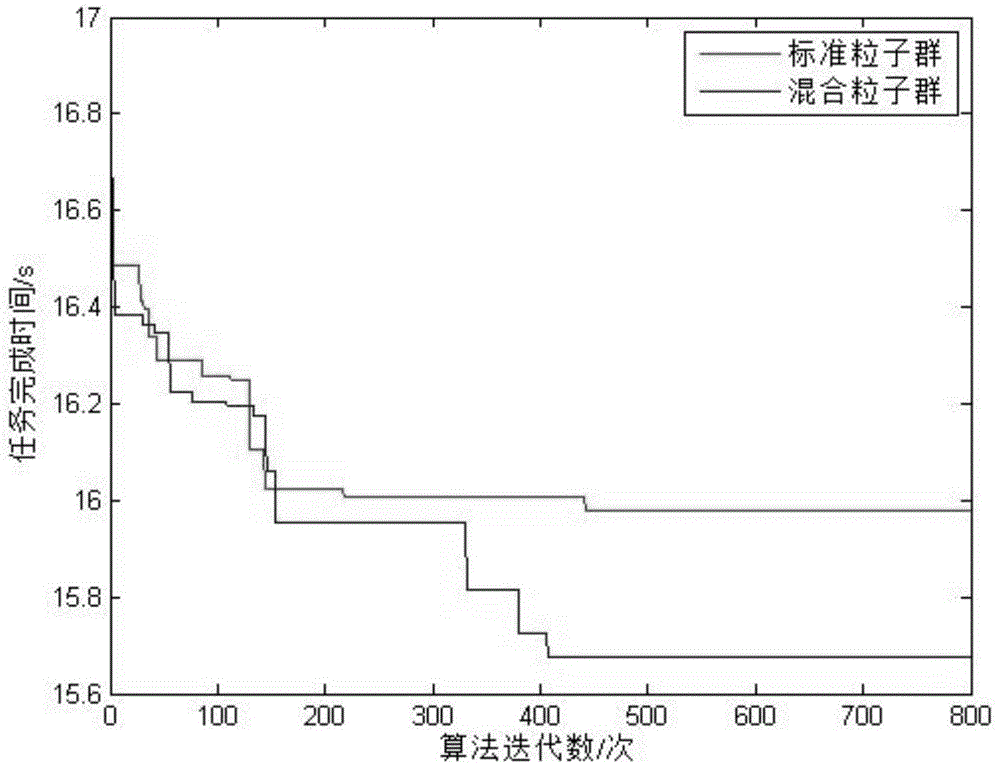

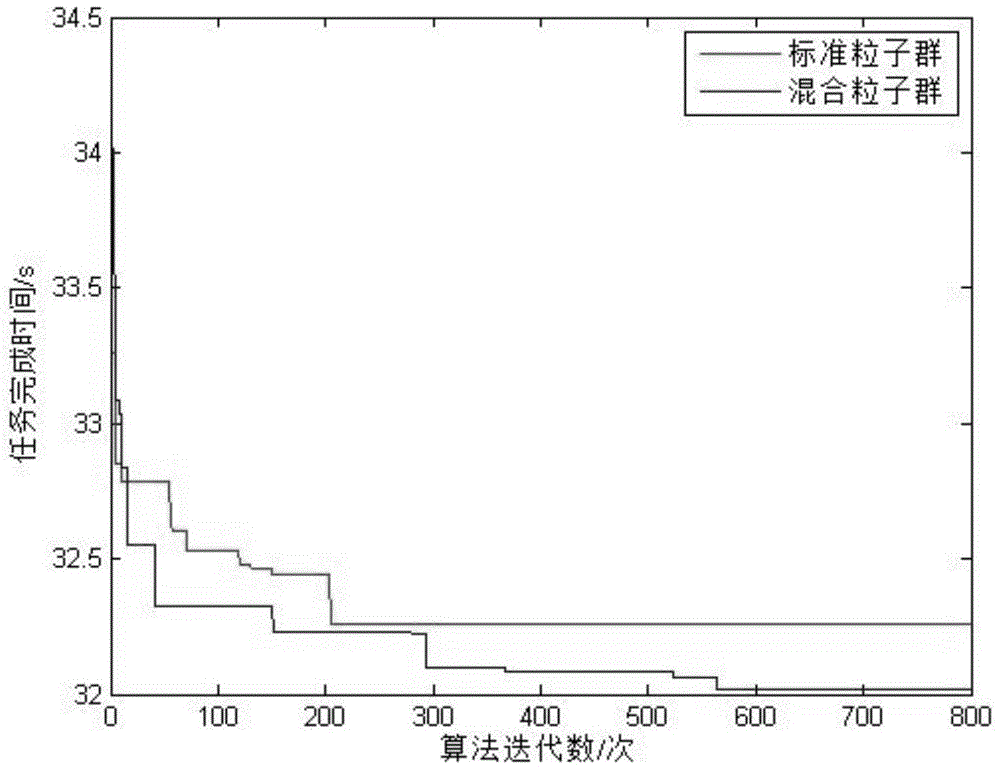

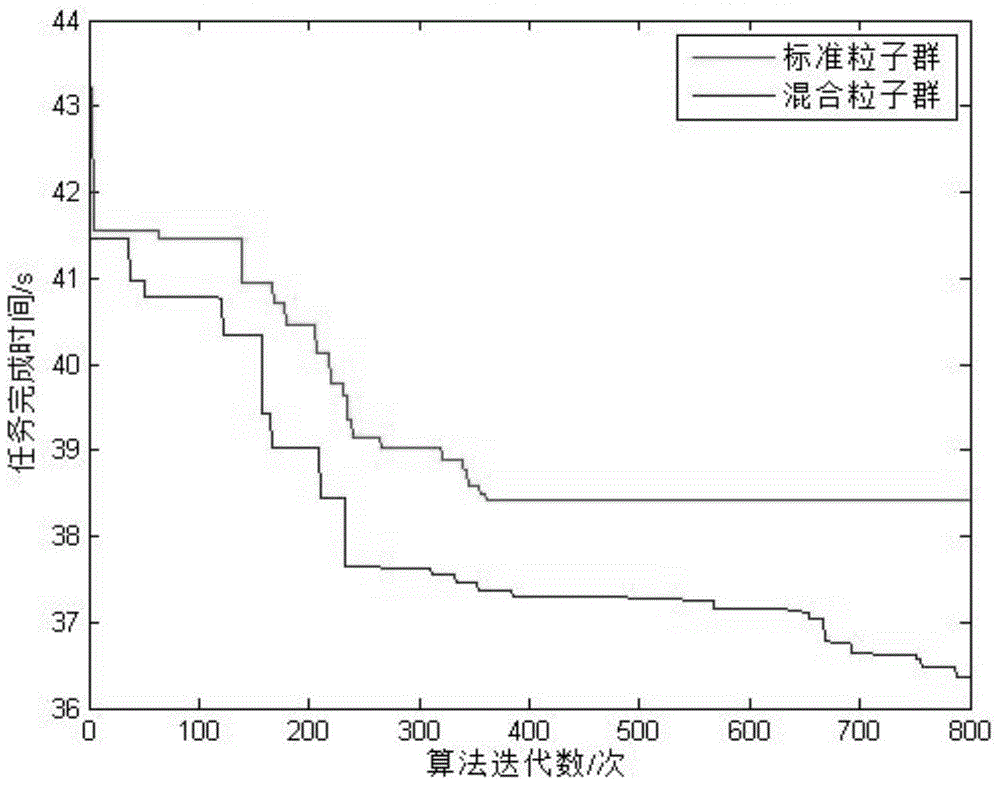

AGV optimization scheduling method based on mixed particle swarm optimization

A hybrid particle swarm and optimal scheduling technology, applied in computing, computing models, genetic models, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] specific implementation

[0049] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

[0050] The present invention is based on the mixed particle swarm algorithm AS / RS transportation system AGV optimal scheduling method, which is specifically implemented according to the following steps:

[0051] Step 1: Set the pick-up / down-package station, entry / exit station (I / O station) and AGV as scheduling objects, abstract their working process into a mathematical model, and determine the objective function of the scheduling plan.

[0052] The goal of AGV optimal scheduling is to find an effective scheduling strategy that can minimize the time it takes for AGV to complete the delivery task. The mathematical model is expressed as follows:

[0053] First define some parameters as follows:

[0054] n: the total number of entry / exit stations;

[0055] S={1,2,...,n}: set of serial number of entry / exit station;

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com