Binocular-vision-based high-precision virtual assembling system algorithm

A technology of virtual assembly and binocular vision, applied in computing, image data processing, special data processing applications, etc., can solve the problems of inability to realize accurate tracking and recognition of gestures, discontinuous gesture recognition, availability of expensive visual information, etc., to achieve accurate Stable 3D real-time tracking, improved efficiency in human-computer interaction, and low-cost architecture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in more detail:

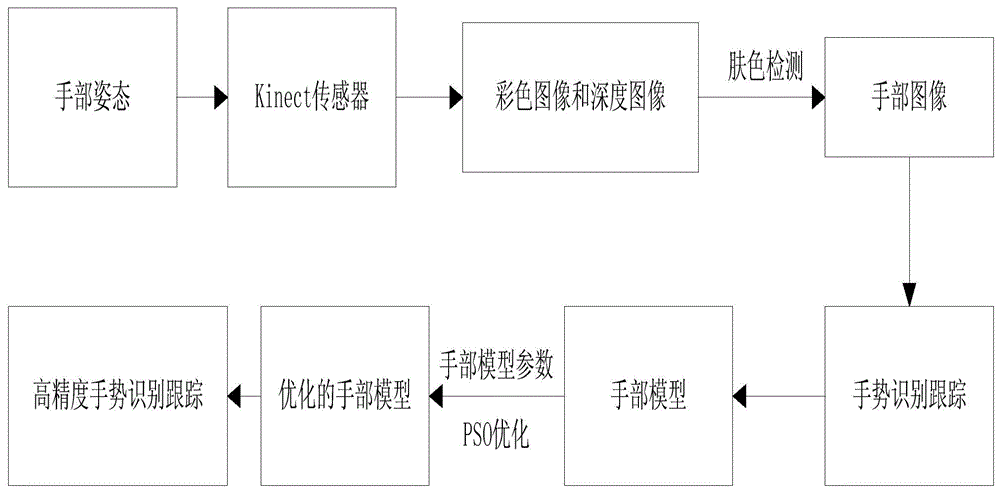

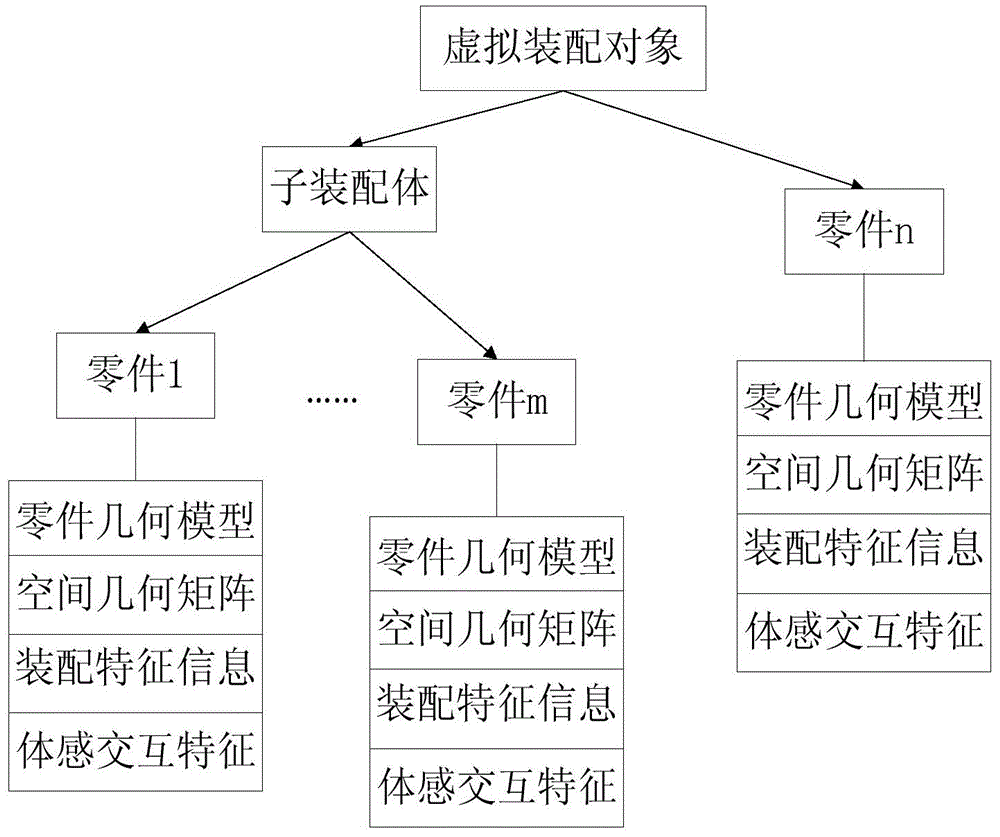

[0025] A high-precision virtual assembly system algorithm based on binocular vision, which mainly relies on the information collected by the Kinect sensor as input, and on the basis of a model-based method, transforms the problem of gesture recognition and tracking into an optimal solution using the improved PSO algorithm. Optimize problems and take advantage of GPUs to improve optimal performance.

[0026] The Kinect sensor is a somatosensory peripheral developed by Microsoft Corporation, which can not only acquire color data, but also acquire depth data, thereby obtaining a depth image.

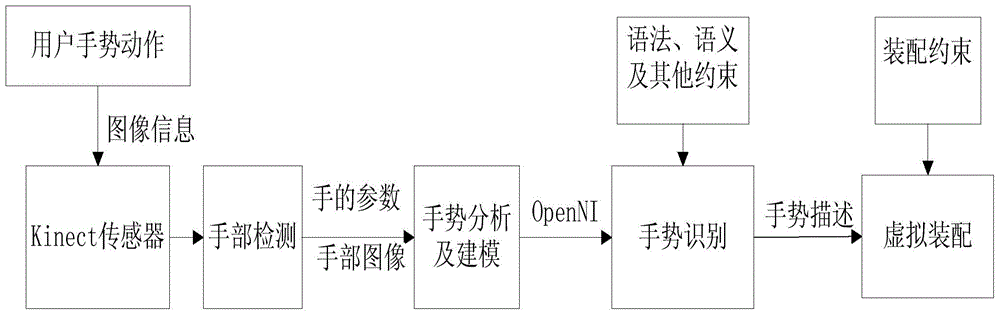

[0027] The algorithm uses the Kinect sensor to collect the user's movement space information, including upper limb movement information, gesture information including static gesture and dynamic gesture information as the input information of the virtual assembly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com