Processing process of lotus-root-core-shaped polytetrafluoroethylene insulation layer for radio frequency cable

A teflon, radio frequency cable technology, applied in the direction of insulating conductors/cables, etc., can solve the problems of large dielectric coefficient and large attenuation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

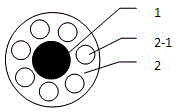

[0018] Such as figure 1 , 2, 3, 4, and 5, a processing technology for a lotus-shaped polytetrafluoroethylene insulating layer for radio frequency cables, which is characterized in that: a layer of lotus root is extruded through an extrusion die outside the silver-plated wire conductor 1 The heart-shaped polytetrafluoroethylene insulating layer 2 constitutes the cable core of the radio frequency cable, and the structure of the lotus heart-shaped polytetrafluoroethylene insulating layer 2 is that several through holes 2- 1.

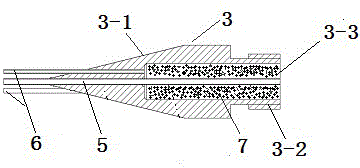

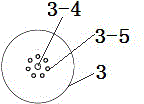

[0019] Above-mentioned extruding mold comprises: pushing inner mold 3, pushing outer mold 4, inner conductor pipe 5, empty pipe 6, one end of pushing inner mold 3 is cone 3-1, and the other end of pushing inner mold 3 is It is composed of two circular bodies with different diameters integrally formed with the cone 3-1, a circle of external thread 3-2 is provided on the small diameter circular body, and an inner mold chamber 3 is provided inside the two...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com