A method and system for improving LED chip sorting efficiency

A technology of LED chips and chips, applied in the fields of sorting, electrical components, semiconductor/solid-state device manufacturing, etc., can solve the waste of manpower and material resources rearrangement operations, adverse effects on yield and yield, affecting sorting efficiency and chip yield, etc. problems, to achieve the effect of reducing the time for picking and distributing Bins, reducing waste of suction and removal, and improving operability and feasibility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

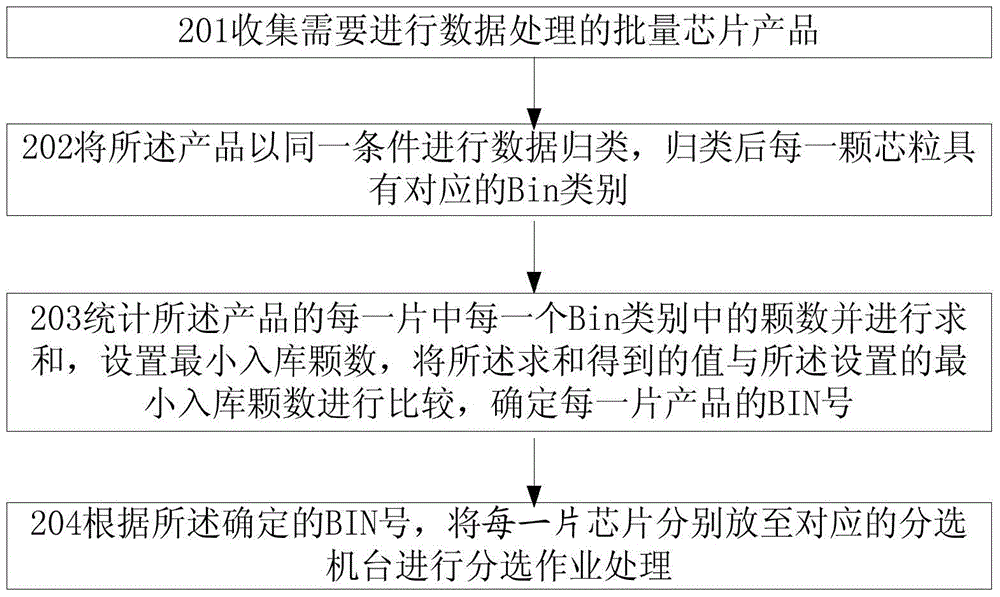

[0048] This embodiment provides a method for improving LED chip sorting efficiency, comprising the following steps:

[0049] Step 201 collects batches of chips that require data processing;

[0050] Step 202 classifies the data of the chips under the same condition. Here, the classification refers to classifying into the same Bin number according to the photoelectric characteristic parameters of the chip. After classification, each chip in each chip has a corresponding Bin category, the Bin category distribution of the classified chips is in a normal distribution state.

[0051] It should be noted that the classification of Bin categories is based on the specific optoelectronic characteristics of the chip, such as wavelength, brightness, operating voltage, etc., according to the requirements of sub-BIN to divide the number of divisions of each optoelectronic characteristic, and then according to the law of arrangement and combination, multiply each number to get the total Acc...

Embodiment 2

[0069] Below, in conjunction with the attached drawings, the present invention will be described with the production order of 34B specifications of 50 chips produced by Xiangneng Hualei Optoelectronics Co., Ltd.:

[0070] 1) Carry out centralized point measurement on the 50 pieces and transfer them to the same condition table, and get the corresponding resorting data after the AOI inspection.

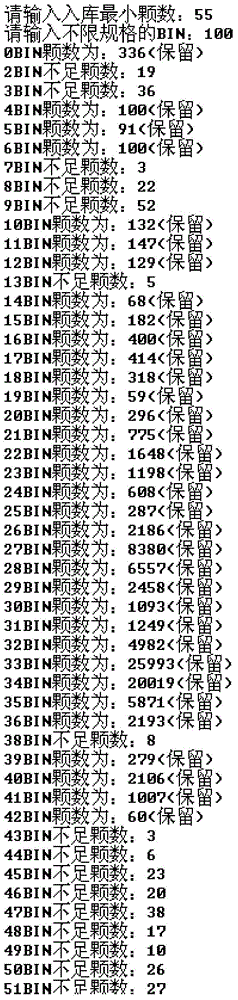

[0071] 2) Perform data processing on the resorting data, and set the minimum number of warehousing to 50. Due to the need for subsequent visual inspection, it may result in insufficient number of warehousing after suction, so the minimum number of warehousing is set during actual operation It is 55 pieces, if the number is not enough, it will be transferred to product B. After the processing, the result program interface is as follows Figure 3a and Figure 3b shown.

[0072] Respectively Figure 3a and Figure 3b The data in represents the meaning for explanation:

[0073] The min...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com