A flue gas denitrification device for co waste heat boiler

A waste heat boiler and flue gas technology, applied in the field of flue gas denitrification, can solve the problems of high safety hazard, not widely used, low denitration efficiency, etc., and achieve the effects of no secondary pollution, reduced investment, and high denitration efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

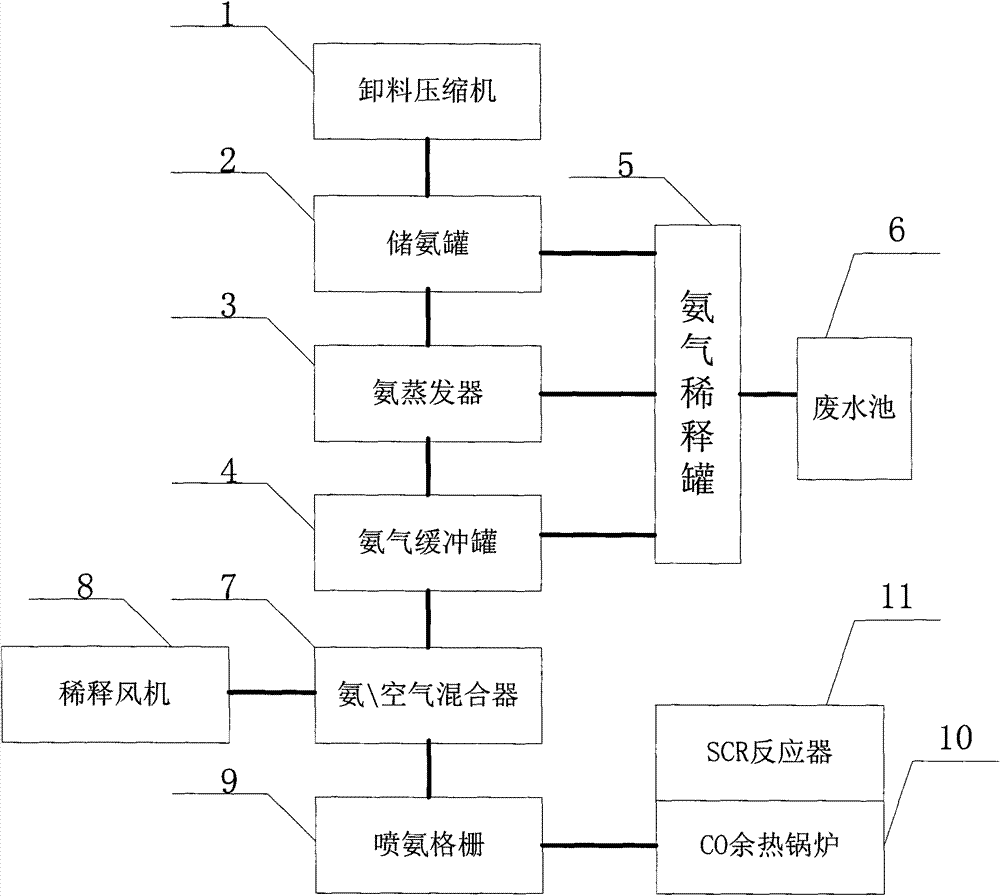

[0021] combined with figure 1 The present invention is described, the present invention is achieved in this way, a novel CO waste heat boiler flue gas denitrification device, the device includes a discharge compressor, ammonia storage tank, ammonia evaporator, ammonia buffer tank, ammonia dilution tank , waste water tank, ammonia\air mixer, dilution fan, ammonia injection grid, CO waste heat boiler, SCR reactor:

[0022] The unloading compressor unloads and compresses the liquefied ammonia transported by trucks;

[0023] The ammonia storage tank is located under the unloading compressor for storing liquid ammonia;

[0024] The ammonia evaporator is connected to the ammonia storage tank through pipelines to vaporize liquid ammonia;

[0025] The ammonia buffer tank is connected to the ammonia evaporator through pipelines, which is used to reduce the speed of ammonia gas and make the ammonia gas more gentle;

[0026] The inlet of the ammonia dilution tank is connected to the a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com