Alignment tool for batch processing

A batch processing and tooling technology, which is applied in the direction of manufacturing tools, metal processing equipment, metal processing machinery parts, etc., can solve the problem of low processing efficiency of a single piece of drilling machine, achieve the effect of low price, enhanced stability, and improved processing progress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

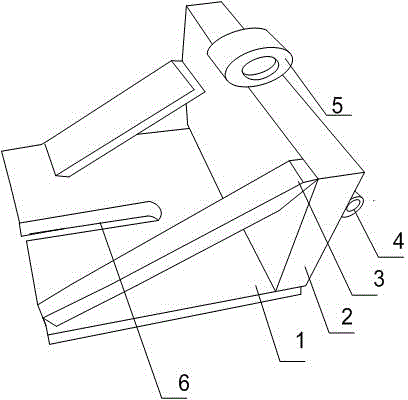

[0014] Such as figure 1 As shown, when drilling in batches, the workpieces to be processed are stacked neatly on the operating table, and they are closely attached to the vertical side formed by the horizontal baffle 1 and the vertical baffle 2, and the stacked workpieces are made by the plane determined by three points. The workpiece is aligned, and the bolt is passed through the positioning hole 6 so that the alignment tool is fixed on the operating table, and then it is drilled by the drilling device.

Embodiment 2

[0016] Such as figure 1 As shown, when the alignment tool is ready to move, it can be realized by mechanical operation: adjusting the first ring lock 5 can make the alignment tool move longitudinally, and adjusting the second ring lock 4 can make the alignment tool move laterally.

Embodiment 3

[0018] Such as figure 1 As shown, the positioning hole 6 in this embodiment may be a square hole or a circular hole.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap