Bearing retainer automatic processing method

A technology of bearing cage and processing method, which is applied in the direction of metal processing, etc., can solve the problems such as application limitations of plastic casting cages, achieve continuous processing, reduce operating procedures, and improve production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The steps and principles of the present invention will be further described below in conjunction with the accompanying drawings.

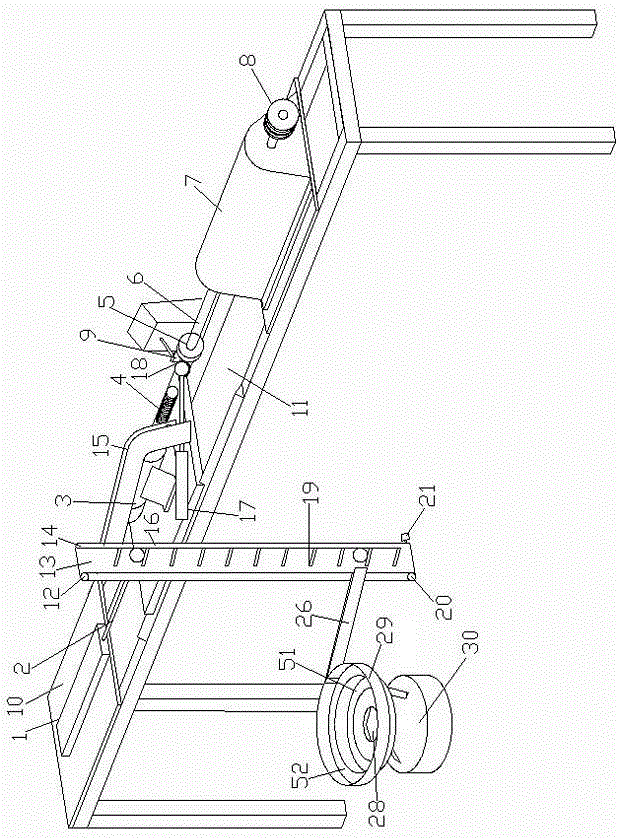

[0035] Embodiment of the present invention, see figure 1 , provides an automatic processing method for a bearing cage, which is used for further finishing and automatic cutting of workpieces to be processed. This is achieved through the following steps:

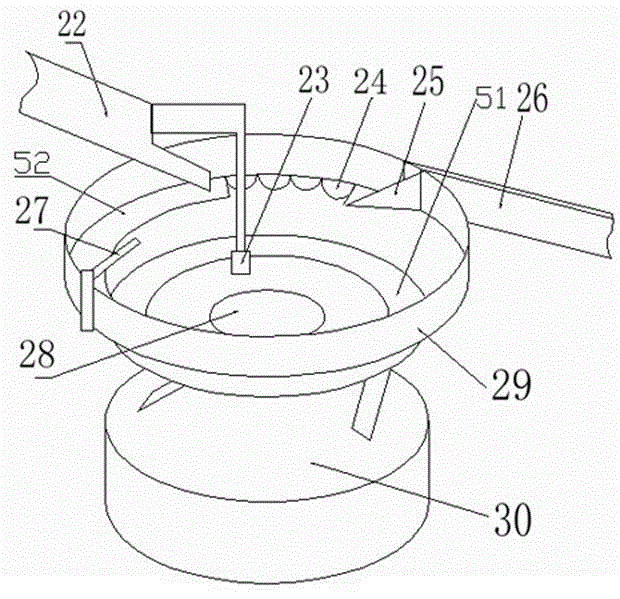

[0036] (1) The workpieces to be processed are sent to the material selection machine through the filling port 22 for screening and arrangement, forming a single and orderly arrangement with the same opening direction;

[0037] (2) A single workpiece to be processed with the same opening direction enters the hoist one by one, and is lifted by the hoist to the height of the machine tool;

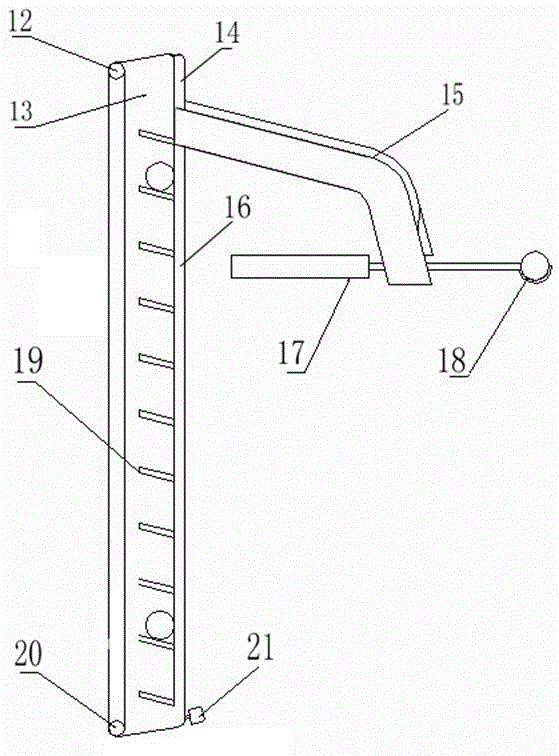

[0038] (3) The workpiece to be processed that has been raised to the height of the machine tool falls into the arc-shaped groove 18, and the arc-shaped groove 18 is pushed by the pusher 17 to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com