Water guiding device of toolroom machine

A technology of machine tools and water guide holes, which is applied in the direction of spraying devices, manufacturing tools, metal processing machinery parts, etc., can solve problems such as waste of working time, leakage of processing fluid, cumbersome problems, etc., and achieve the effect of fast and precise adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

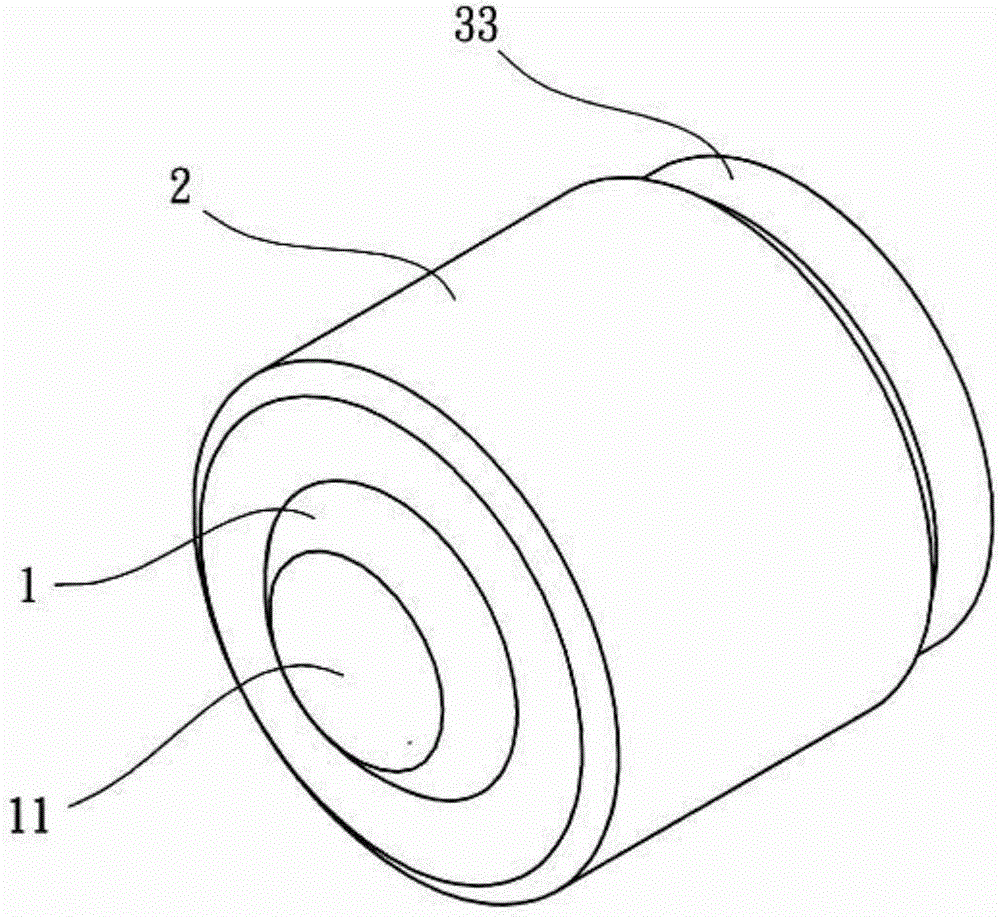

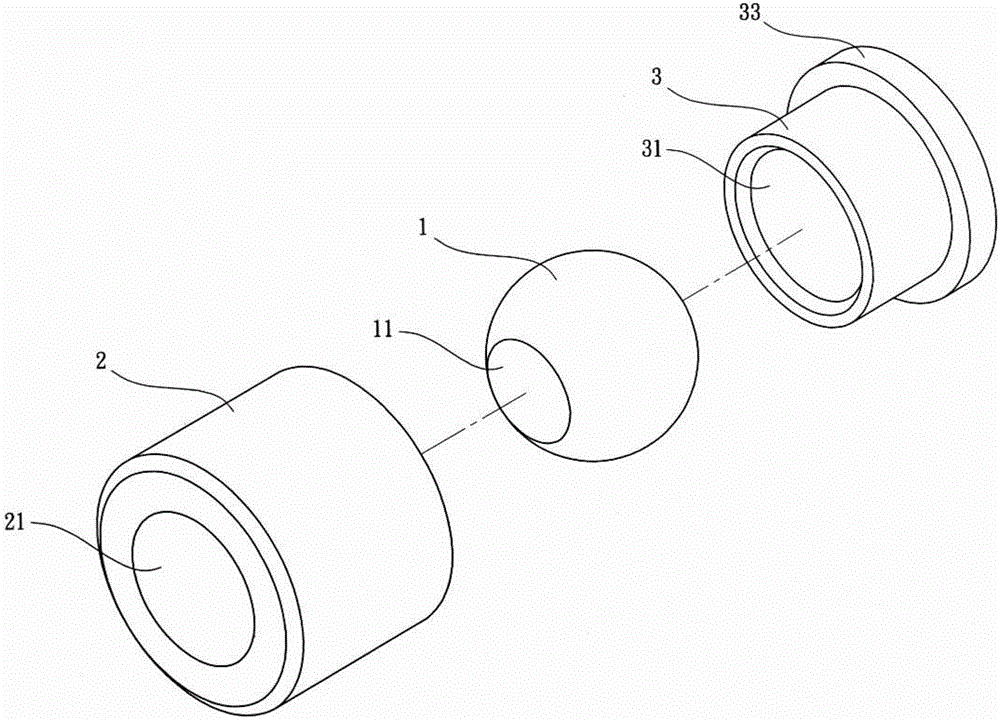

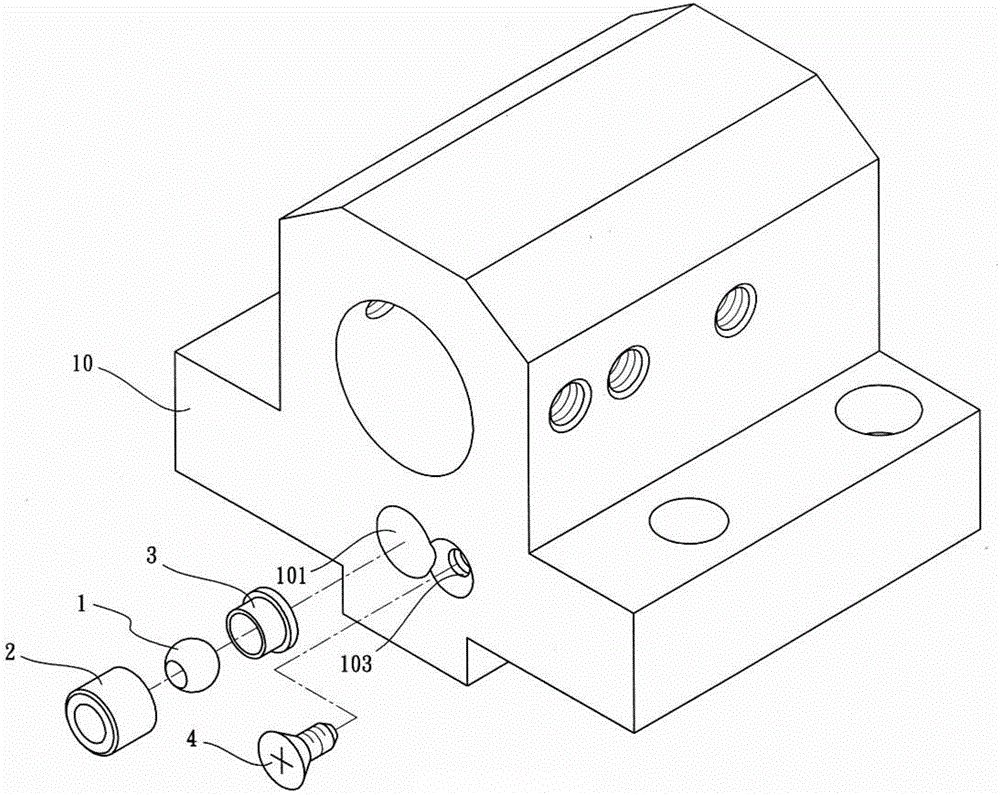

[0044] see Figure 1 to Figure 5 As shown, the present invention is installed on the water guide seat 10. The present invention is a "water guide device for machine tool", which is the first embodiment of the present invention, and it includes a water ball 1, and a water spray hole 11 is formed through it. ; a pressure guide sleeve 2, which is provided with an accommodating hole 21, and the water ball 1 is accommodated in the accommodating hole 21; a leak-proof component 3, which is provided with a water guide hole 31 and a water spray hole 11 and The accommodating hole 21 is connected, and one end of the anti-leakage component 3 is pierced with the accommodating hole 21 and contacts the periphery of the water ball 1, and the anti-leakage component 3 is made of plastic or copper; and a pan head screw 4, which can be screwed on the On the water guide seat 10, and the top end of the dish head screw 4 is pressed against the top of the pressure guide sleeve 2.

[0045] According ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com