Heating evaporation system for high-level automatic oil supplement alkali liquid concentration

A technology of automatic oil replenishment and heating evaporation, applied in the fields of alkali metal compounds, sustainable manufacturing/processing, alkali metal oxides/hydroxides, etc., can solve the problems of low heat conduction efficiency, inability to improve the efficiency of lye concentration, and air pollution and other issues, to achieve high heat conduction efficiency, improve efficiency, and improve work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

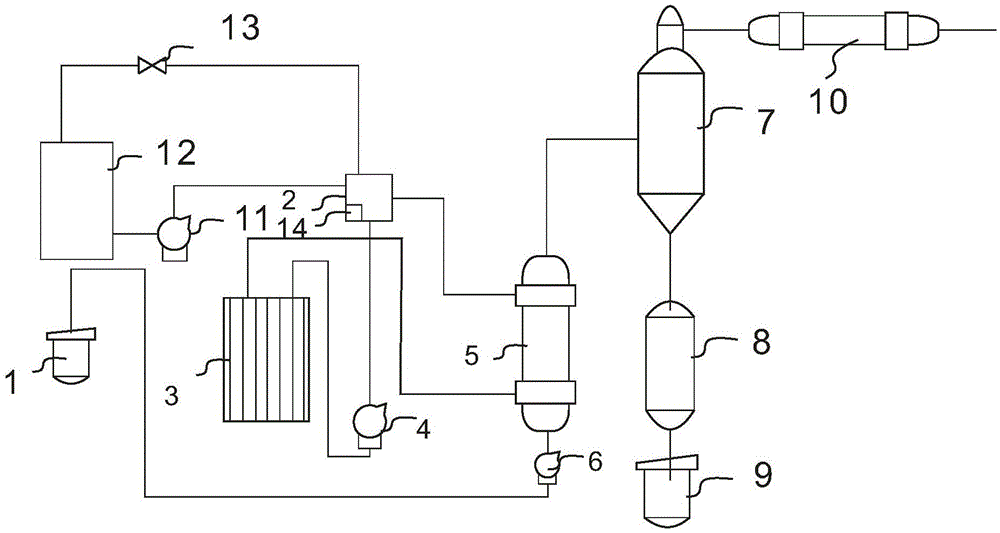

[0012] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and preferred embodiments.

[0013] As shown in the figure, the present invention includes an lye heating chamber 5, a light alkali storage tank 1 connected to the bottom of the lye heating chamber through a lift pump 6, and a separation chamber 7 arranged at the top of the lye heating chamber, the lye heating chamber The oil storage chamber 2, the heat conduction oil circulation pump 4 and the heat conduction oil heating chamber 3 are connected in series between the two heating ends. The top of the separation chamber is connected to a vacuum condenser 10, and the vacuum condenser is connected to a condensate discharge pipe. The bottom of the separation chamber is connected to the liquid accumulation tank 8, the lower part of the liquid accumulation ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com