High-speed cotton type comber cotton web transmission protection device

A protection device and technology of combing machine, applied in the direction of combing machine, textile and papermaking, fiber processing, etc., can solve the problems of unclear cotton net, holes in cotton net, burrs, etc. The effect of breaking holes and improving shape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

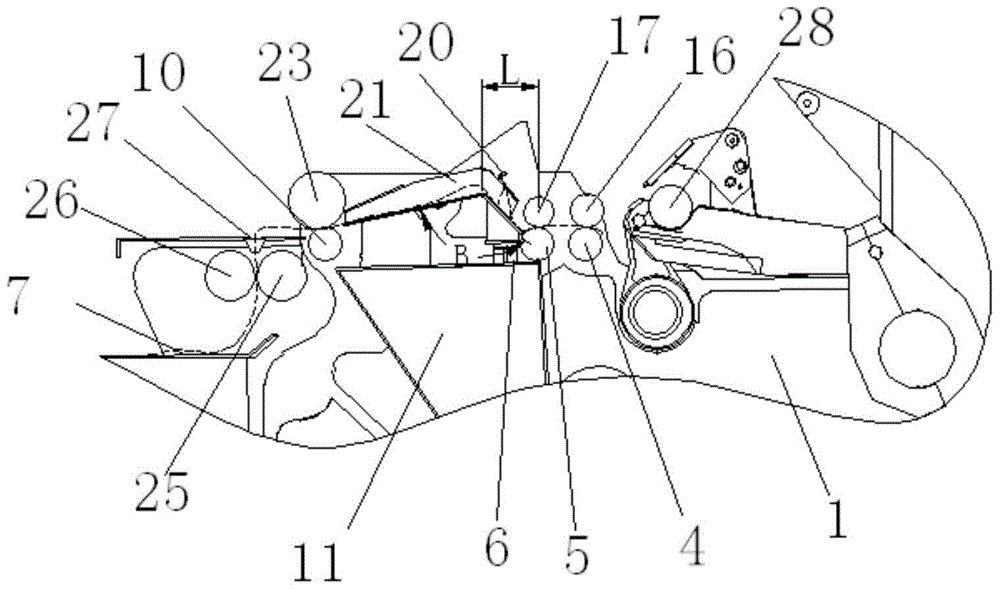

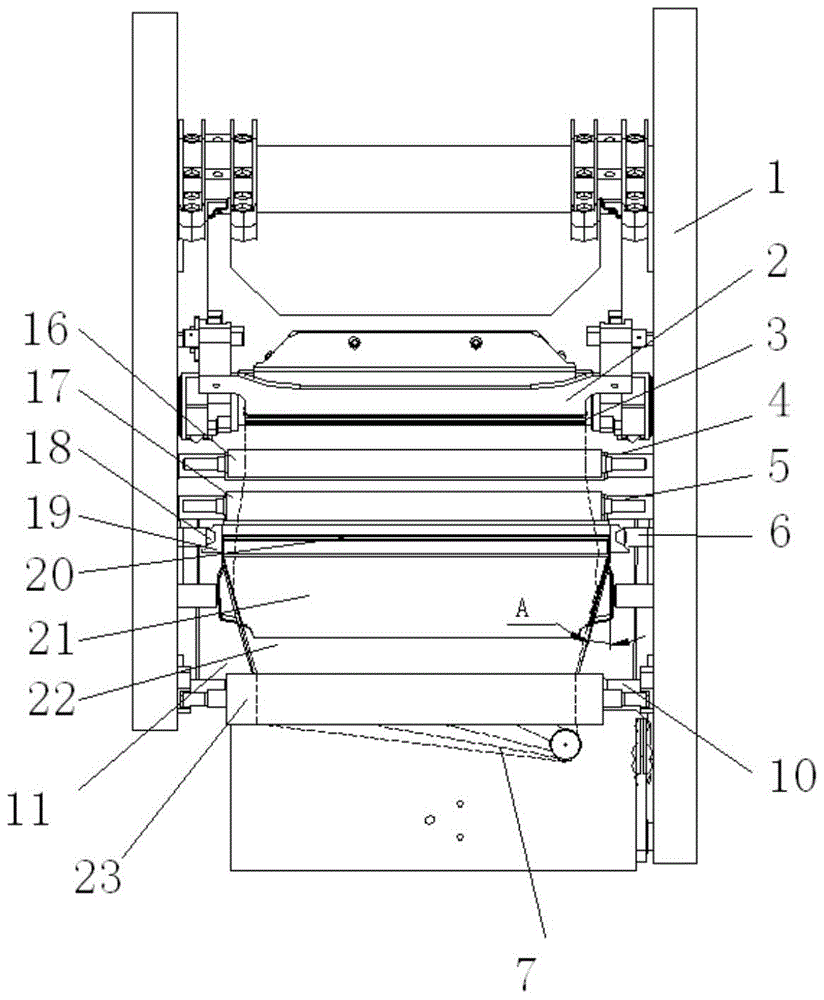

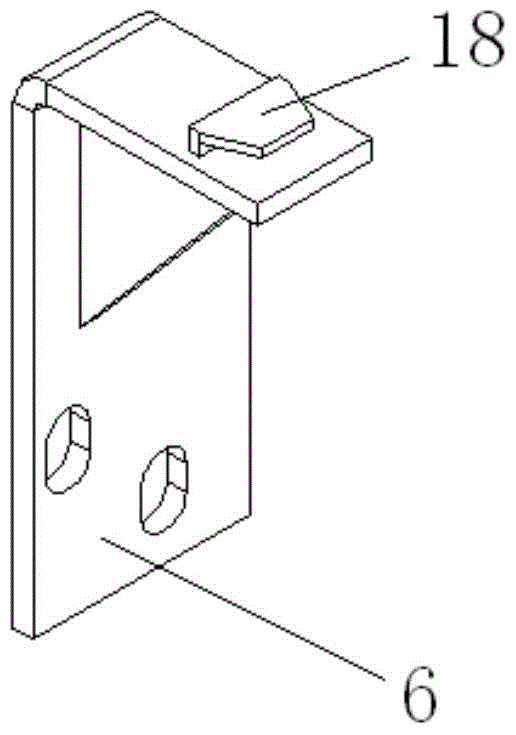

[0019] Embodiment: A high-speed cotton-type combing machine cotton web transmission protection device, which sequentially includes a cotton web forming mechanism composed of a first separating roller 16 and a first separating roller 4 along the moving direction of the cotton web, and a trumpet-shaped sliver forming mechanism 27 and the sliver extruding mechanism that is made up of the first and second pressure rollers 25, 26, the first separation top roller 16 of the cotton web forming mechanism and the first separation roller 4 and the first and second sliver extrusion mechanisms The pressure rollers 25 and 26 are respectively arranged in parallel and rotated correspondingly and positioned on the wall plate 1 in the combing machine to realize the conveyance of the cotton web 7, and the sliver extruding mechanism is located at the trumpet-shaped sliver forming mechanism 27 along the moving direction of the cotton web. On the side with the small opening, the middle wall panel 1 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com