Linear motion device

A technology of linear motion and sliding parts, which is applied in the direction of transmission devices, belts/chains/gears, mechanical equipment, etc., can solve problems such as loss of position, achieve the effect of simplifying assembly and improving adjustment accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

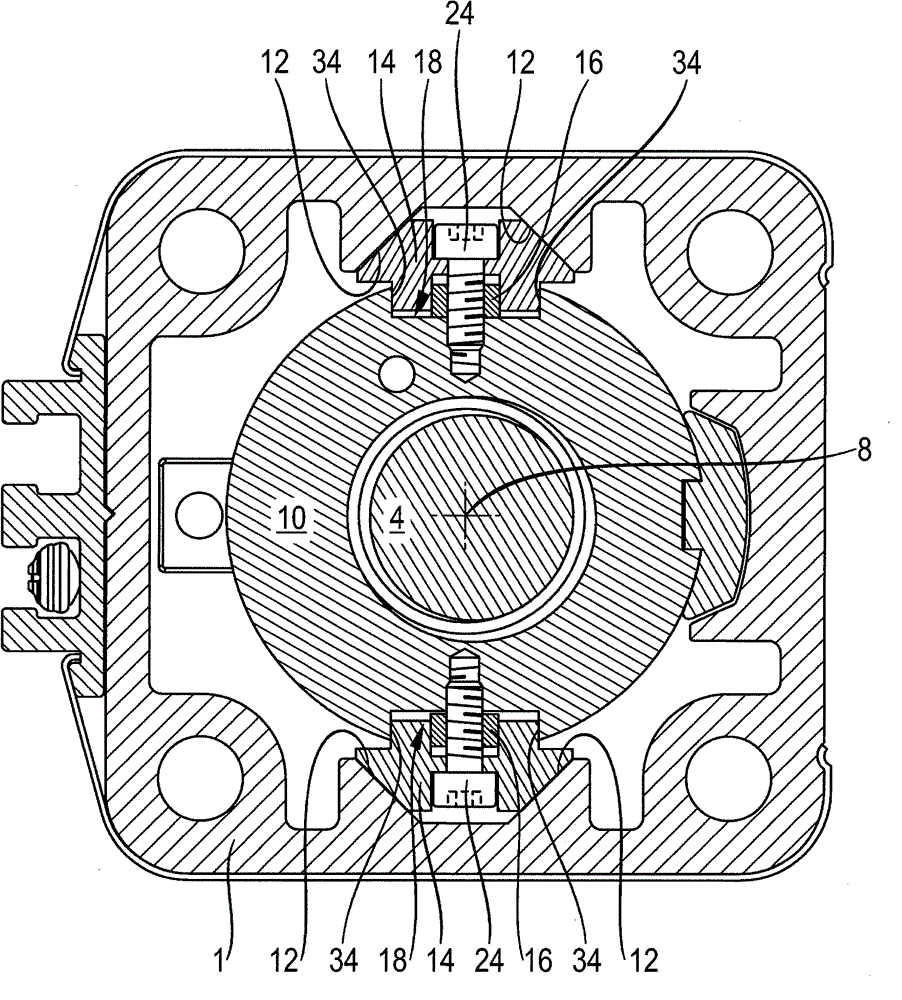

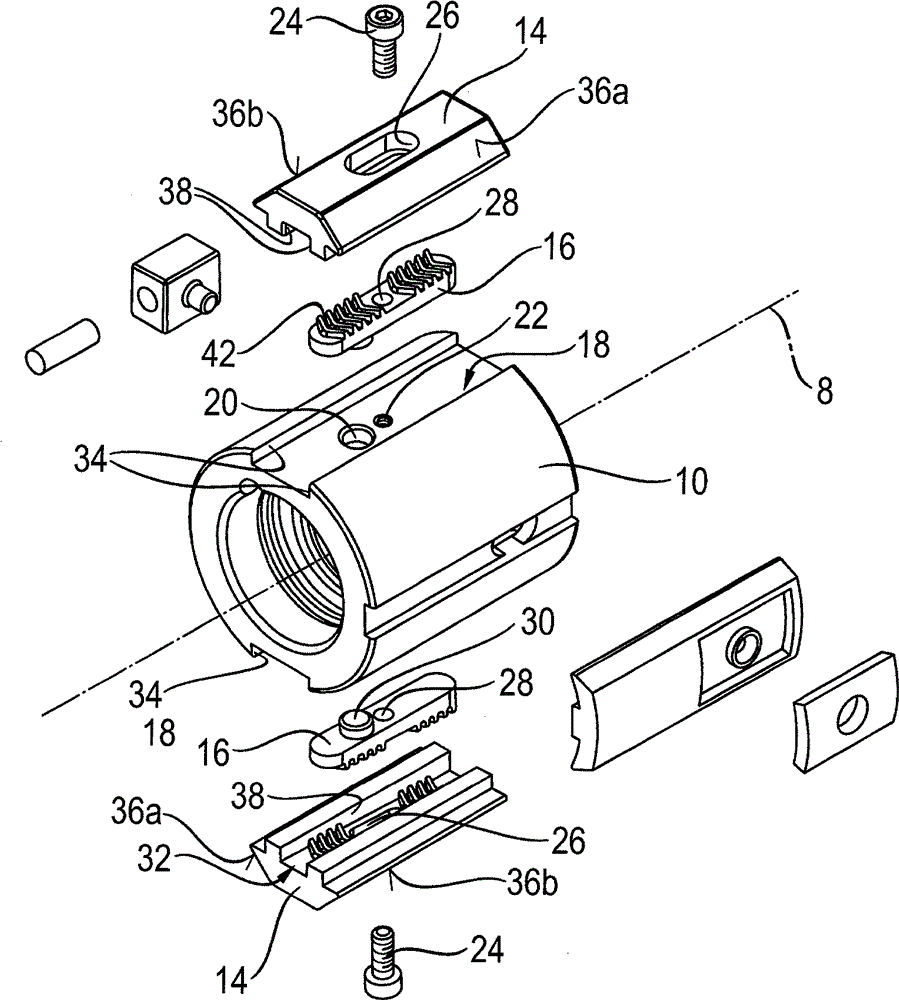

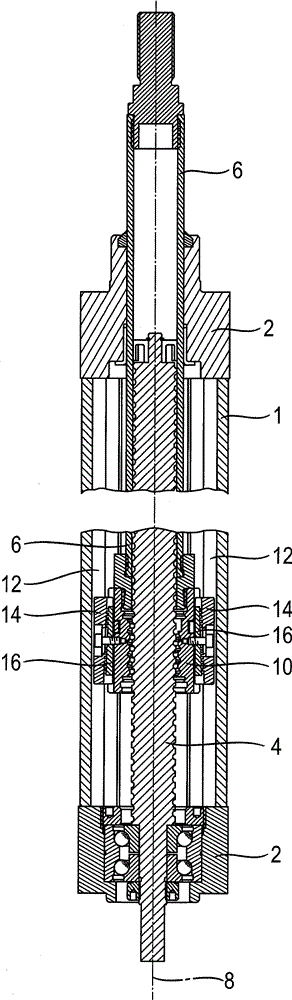

[0028] figure 1 An embodiment of the linear motion device according to the invention is shown in a side sectional view. It has an approximately square, elongated housing 1 in cross section, which is closed at the end faces by means of two caps 2 . exist figure 1 The end section of a threaded spindle 4 is supported in the lower cover 2 via a rolling bearing, and in figure 1 A cantilever 6 movable relative to the housing 1 is slidably supported in the upper cover 2 in the middle. exist figure 1 The upper end section of the cantilever 6 protrudes from the housing 1 . A device (not shown) which is to move along the longitudinal axis 8 of the linear movement device can be coupled to this end section.

[0029] exist figure 1 The lower end section of the cantilever arm 6 is fastened to a spindle nut 10 which is slidably supported in the housing 1 . The spindle nut 10 and the threaded spindle 4 are in active engagement with each other via a row of annularly encircling balls (no...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com