Erosion-resisting tube

A technology for anti-corrosion pipes and pipe bodies, which is applied in the direction of hoses, pipes, rigid pipes, etc. It can solve the problems of inability to use high water pressure, limited external tension of pipes, and poor anti-corrosion effect of pipes, so as to achieve the pressure of dispersed water , good anti-corrosion effect, increase the effect of tension resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] In order to further illustrate the present invention, further describe below in conjunction with accompanying drawing:

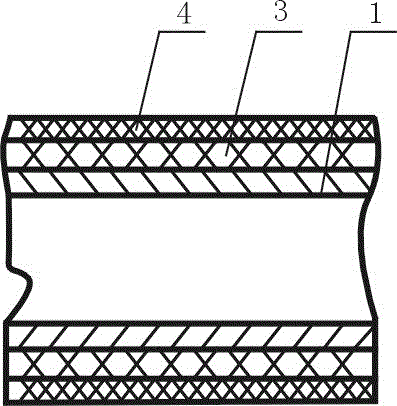

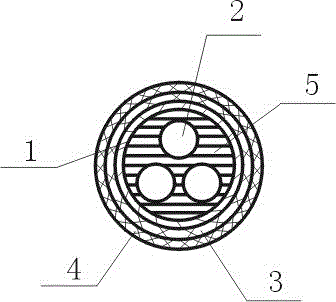

[0014] Such as figure 1 and figure 2 As shown, an anti-corrosion pipe of the present invention includes a pipe body 1, at least one through hole 2 is arranged equidistantly along the axial direction of the pipe body 1, and the outer wall of the pipe body 1 is sequentially provided with a 150-250 μm epoxy powder coating layer 3 and The polyethylene powder coating layer 4 is 450-550 μm, and the through-hole 2 and the adjacent through-hole 2 are provided with a partition wall 5 for partition, and there are three through-holes 2 .

[0015] The anti-corrosion pipe of the present invention has good anti-corrosion effect, can effectively prolong the service life, can effectively offset the external tension generated by the water pressure in the pipe body, and greatly increase the tension resistance of the pipe body. The epoxy powder coating is adsor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com