LED (Light Emitting Diode) light source module

A technology of light-emitting diodes and light source modules, which is applied in the direction of light sources, electric light sources, point light sources, etc., can solve the problems of uneven light output from light source modules, affecting lighting effects, and reduced light utilization of light source modules, and achieve uniform scattering , the effect of loss reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

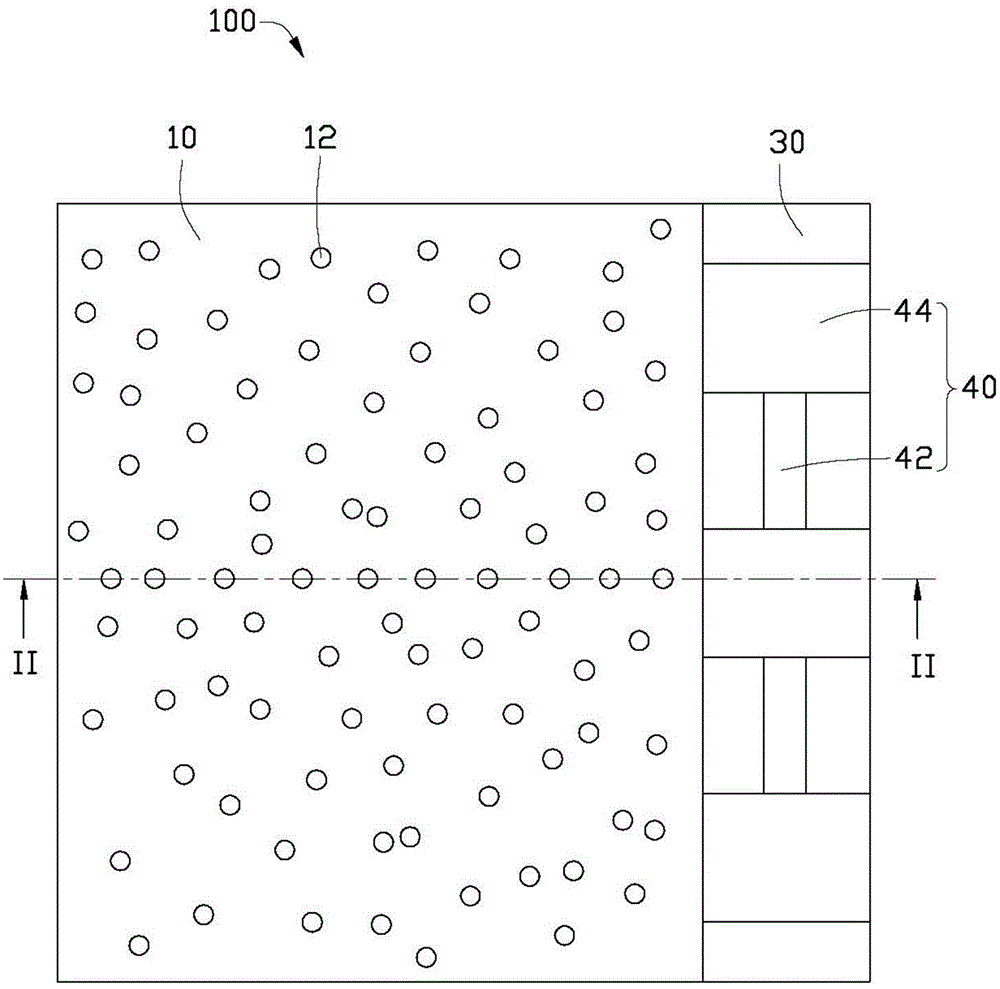

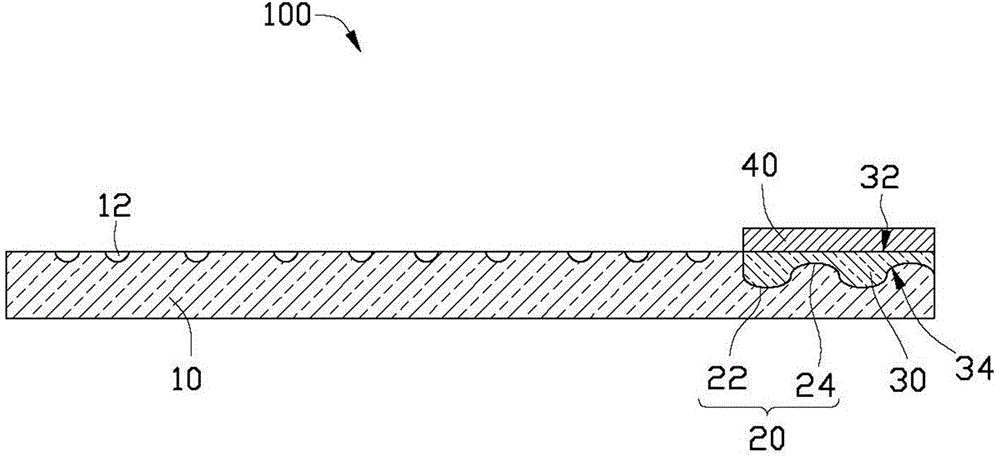

[0013] See figure 1 and figure 2 , The light-emitting diode light source module 100 of an embodiment of the present invention includes a light guide film 10, an optical microstructure 20 formed on one side of the light guide film 10, a colloid layer 30 disposed on the optical microstructure 20, and The colloidal layer 30 is provided with a light-emitting diode light source 40.

[0014] The light guide film 10 is made of a transparent material, such as polycarbonate (PC), polymethyl methacrylate (PMMA), or optical glass. Preferably, the light guide film 10 is a flexible film, which can be bent into a desired shape and can achieve the effect of lightness and thinness.

[0015] The optical microstructure 20 is formed by recessing one side of the light guide film 10 inward. In this embodiment, the optical microstructure 20 is formed on the top surface of the light guide film 10. Understandably, the optical microstructure 20 may also be formed on the bottom surface or side surface of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com