Novel bottle inspection light box

A light box, a new type of technology, applied in lighting and heating equipment, lighting devices, instruments, etc., can solve the problems of poor inspection effect of bottled products, unsatisfactory light inspection effect, high labor intensity, etc. Light inspection effect, the effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

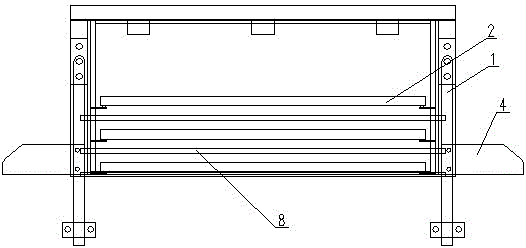

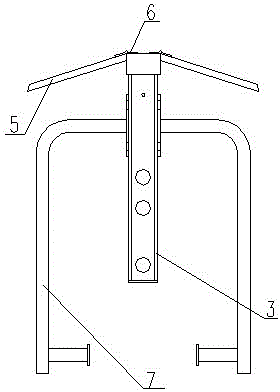

[0015] A new type of bottle inspection light box, comprising a frame light frame 1, inside the frame light frame 1 there are several horizontally installed light tubes 2, and the frame light frame 1 is provided with light guide plates 3 on the front and rear sides, the frame The left and right ends of the frame-type lamp frame 1 are provided with splitter plates 4, and the upper end of the frame-type lamp frame 1 is provided with reflectors 5 respectively.

[0016] The splitter plate 4 of the present invention is triangular, the rear end of the splitter plate 4 is connected to the front and rear sides of the frame lamp holder 1, and the front end of the splitter plate 4 is pointed.

[0017] The reflector 5 of the present invention is connected to the upper end of the frame lamp holder 1 through a hinge 6 .

[0018] The front and back sides of the left and right sides of the frame-type lamp holder 1 according to the present invention are respectively provided with clip mounting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com