Measuring device for measuring oil consumption of oil lubricating equipment

A measuring device, oil lubrication technology, applied in measuring device, relative volume flow measurement, liquid/fluid solid measurement, etc., can solve the problems of complex structure, huge volume, inability to simulate engine operating conditions, etc., to achieve simplified structure, volume reduced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

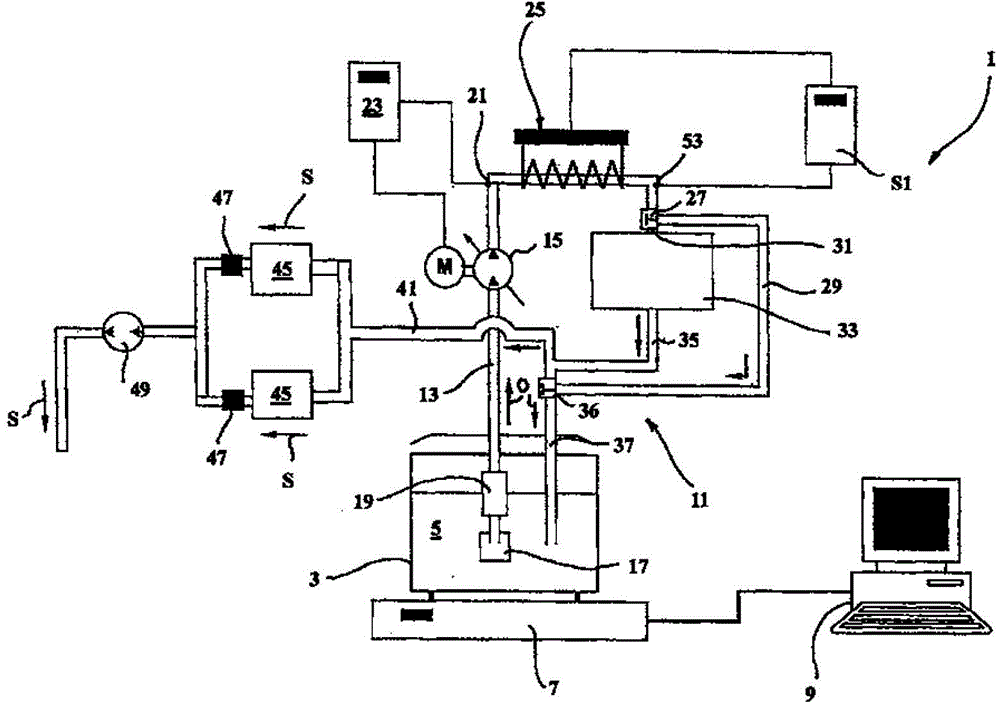

[0024] The measuring device of the present invention will be described in detail below with reference to the accompanying drawings.

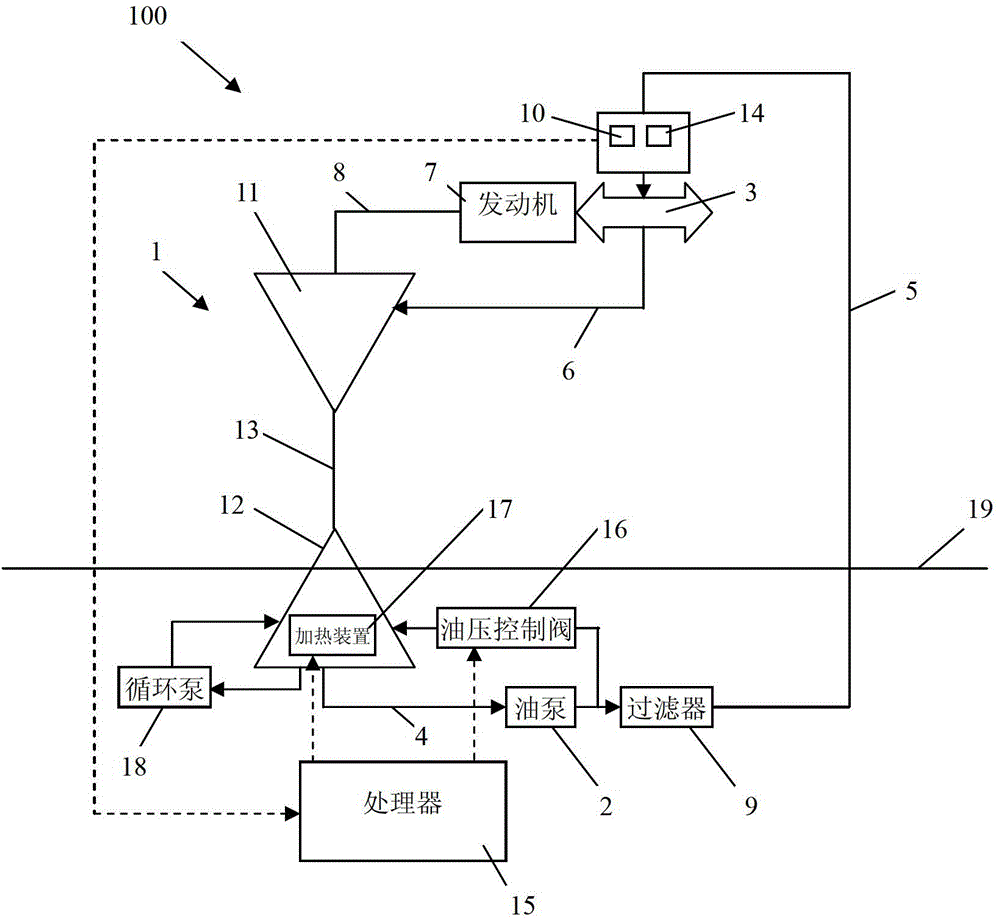

[0025] image 3 Taking the turbocharger 3 as an example, a schematic diagram of the oil circuit of the measuring device 100 according to the present invention is shown.

[0026] The measuring device 100 includes an upper fuel tank 11 and a lower fuel tank 12 forming the fuel tank 1, and an observation tube 13 is communicated between the upper fuel tank 11 and the lower fuel tank 12. The observation tube 13 is preferably a rigid transparent tube, and its side wall is provided with a metering scale. To read the amount of oil in the lower fuel tank 12 when the measuring device 100 stops running. The upper oil tank 11 and the lower oil tank 12 are arranged up and down so that the observation tube 13 extends vertically, thereby reducing the deposition of lubricating oil on the inner wall of the observation tube 13 to enhance the accuracy of the meas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com