Light-emitting diode packaging structure

A technology of light-emitting diodes and packaging structures, which is applied in the direction of electrical components, electric solid devices, circuits, etc. It can solve problems such as wire offset, difficult crystal bonding, and circuit breakage, and achieve the effect of increasing the active area and improving stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

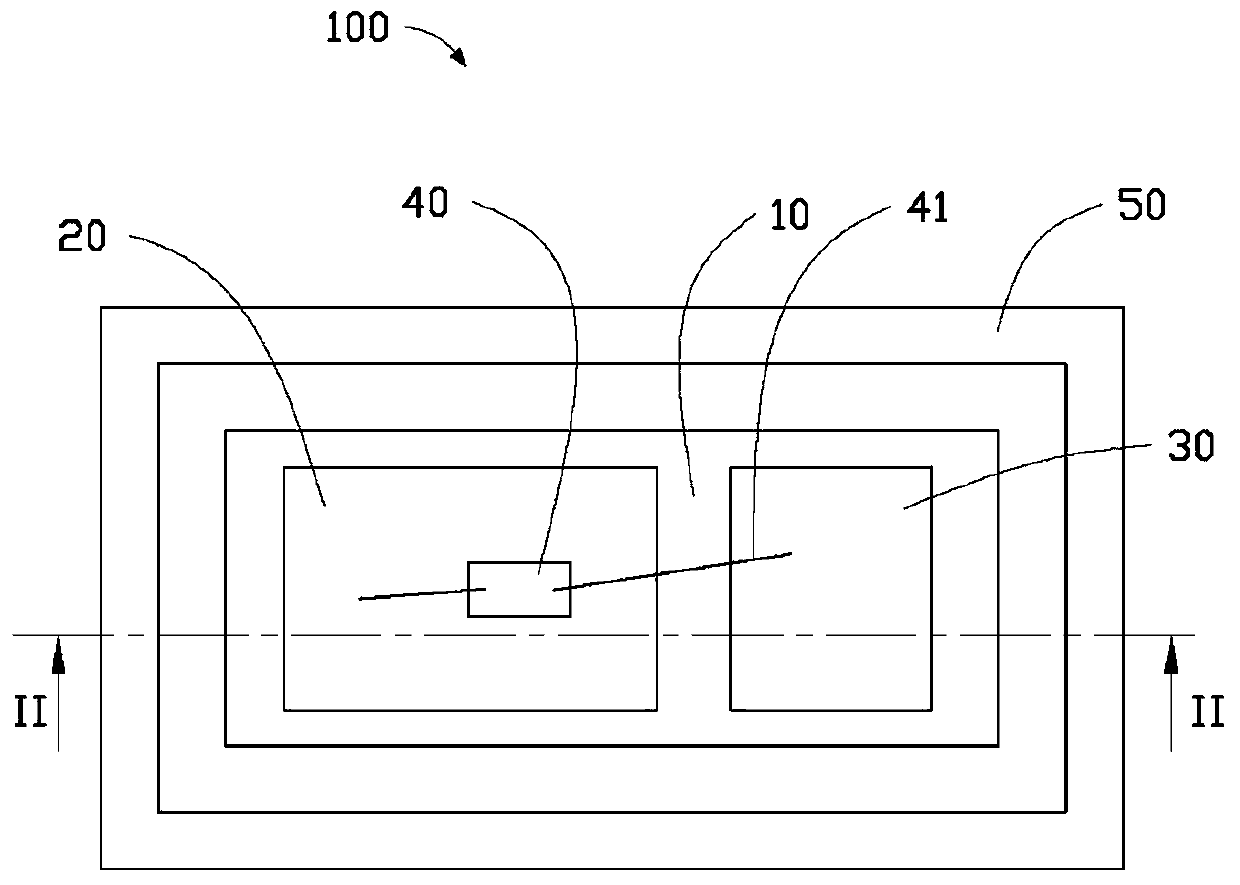

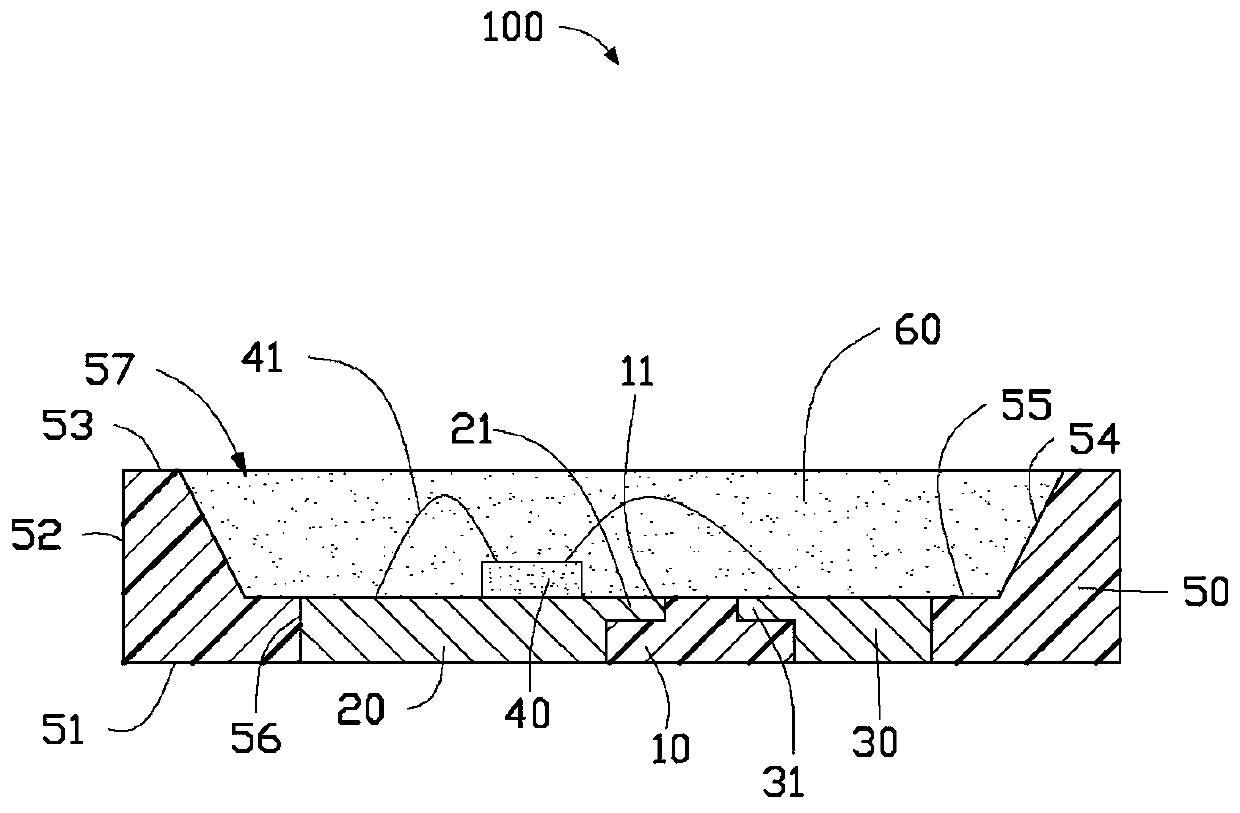

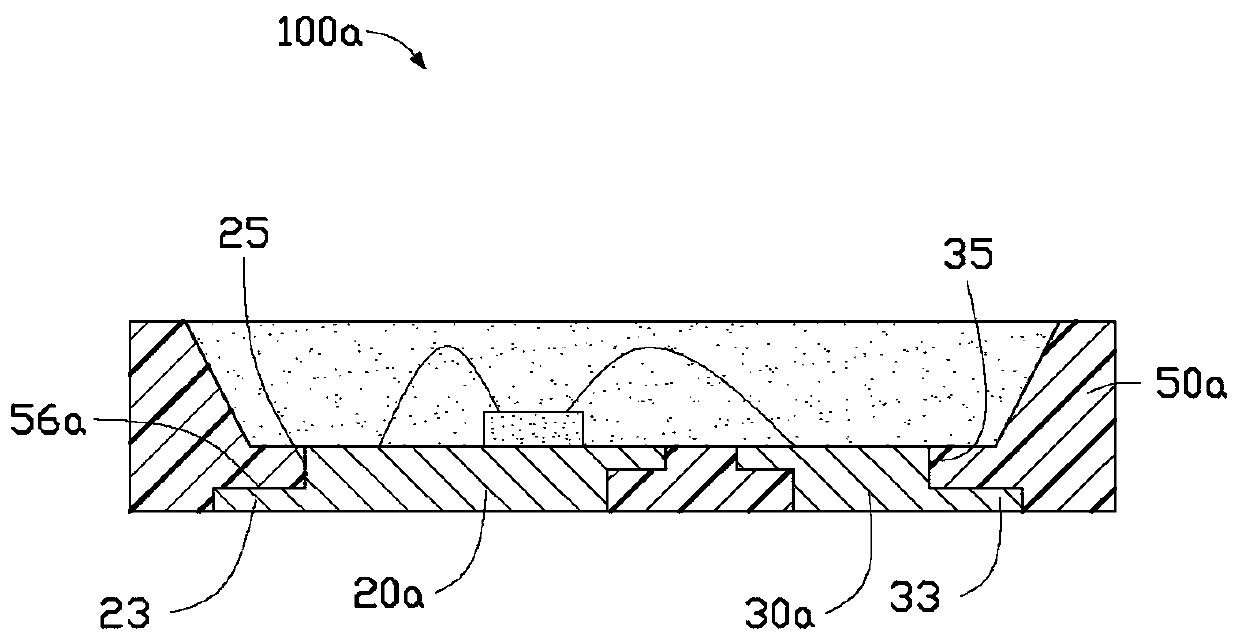

[0012] see figure 1 and figure 2 The light emitting diode packaging structure 100 according to the first embodiment of the present invention includes a substrate 10 , a first electrode 20 and a second electrode 30 located on opposite sides of the substrate 10 , a light emitting diode 40 fixed on the upper surface of the first electrode 20 , A reflective cup 50 fixed on the outer end surfaces of the first electrode 20 and the second electrode 30 and a packaging body 60 filled in the reflective cup 50 .

[0013] The substrate 10 is made of insulating material, and its longitudinal section is in an inverted T shape with a small top and a large bottom, so that two steps 11 are formed on opposite sides thereof. The substrate 10 is used to electrically isolate the first electrode 20 and the second electrode 30 .

[0014] The longitudinal section of the first electrode 20 is rectangular, and its upper end protrudes outward near an inner end surface of the substrate 10 to form a fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com