Special timing power strip for charging battery car

A technology for power strips and battery cars, which is applied to circuits, electrical components, vehicle connectors, etc. It can solve the problems of not being able to automatically cut off the power, more than ten small parts overnight, expansion and deformation of the outer shell, and shortened life. It achieves high cost performance, The effect of prolonging life and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

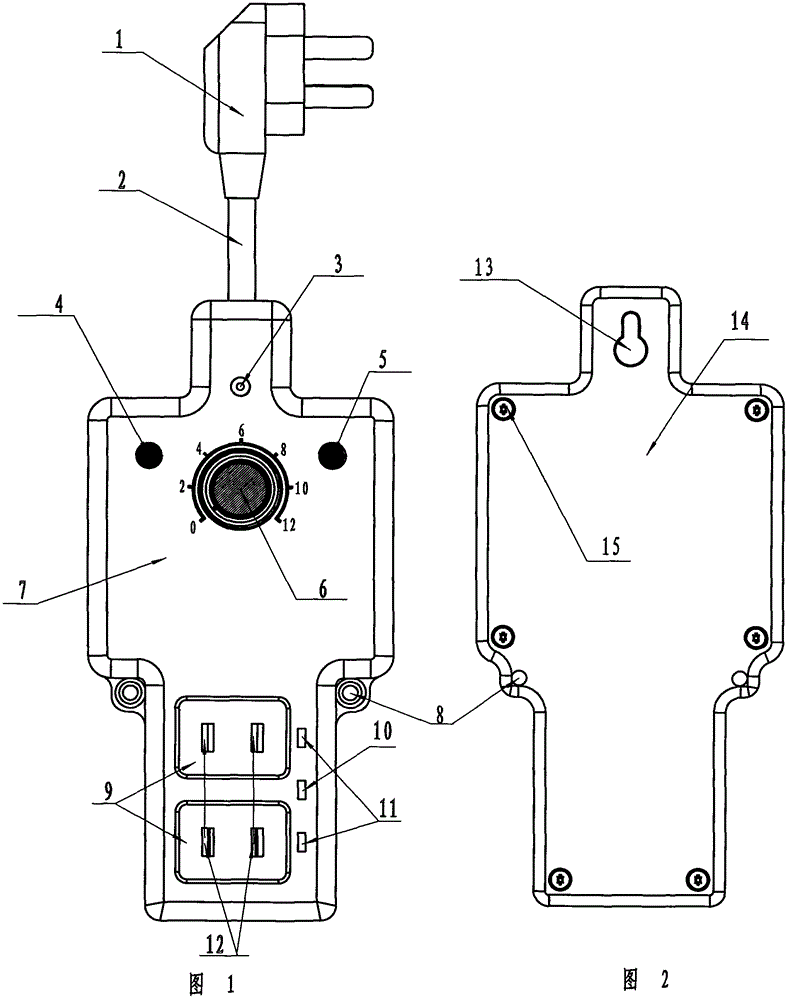

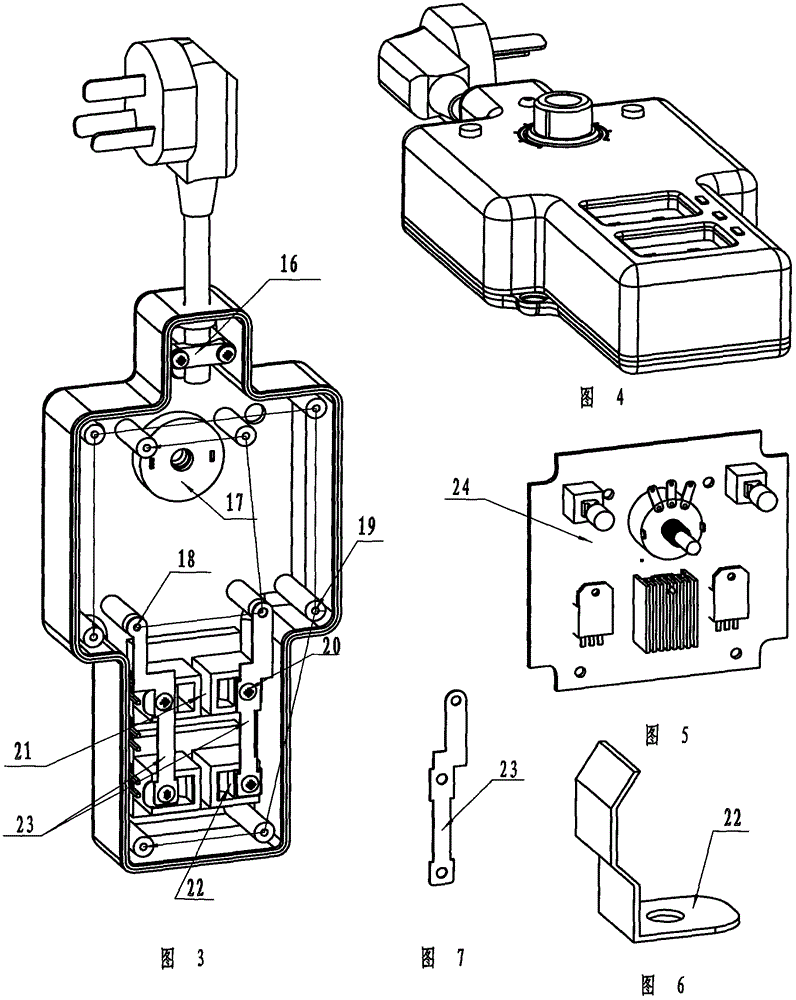

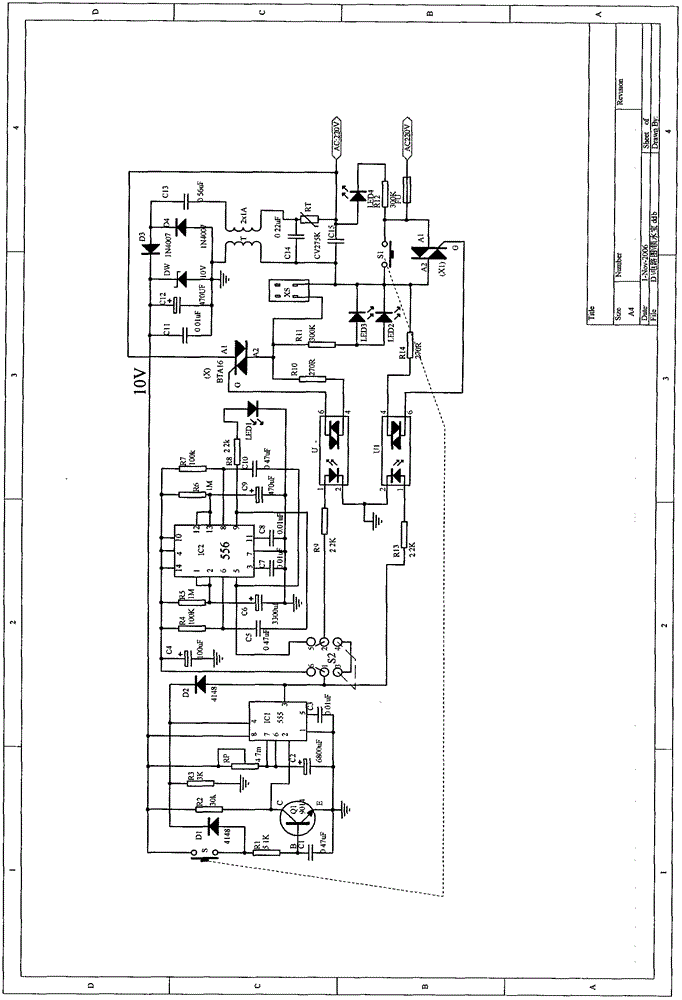

[0021] One end of the power cord (2) is connected to the power plug (1), and the other end extends into the front shell (7) of the plug-in main body to connect with the circuit board (24). The circuit board (24) is put into the inner upper part of the front shell (7) of the plug-in main body, and is fixed on the circuit board fixing pile (18) with 4 self-tapping screws, and the clamp (22) is inserted into the square hole slot ( 21), press the connecting piece (23) on the top of the clamping piece (22), connect the upper end with the circuit board (24), fix it with the clamping screw (20), and put two red and one green three The LED diodes are inserted into the three fixing holes, and are connected to the circuit board through the connector wires, and finally the rear cover is installed on the front shell (7) of the main body of the plug-in strip using fastening screws (15) and rear cover fixing piles (19). ) to fix, and then install the timing knob (6) to complete. Circuit sc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com