Motor controller

A control device and motor technology, applied in the direction of single motor speed/torque control, torque pulsation control, measuring device, etc., can solve the problems that digital operations cannot follow the speed, complicated circuit structure, etc., and achieve high-precision control and circuit structure simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

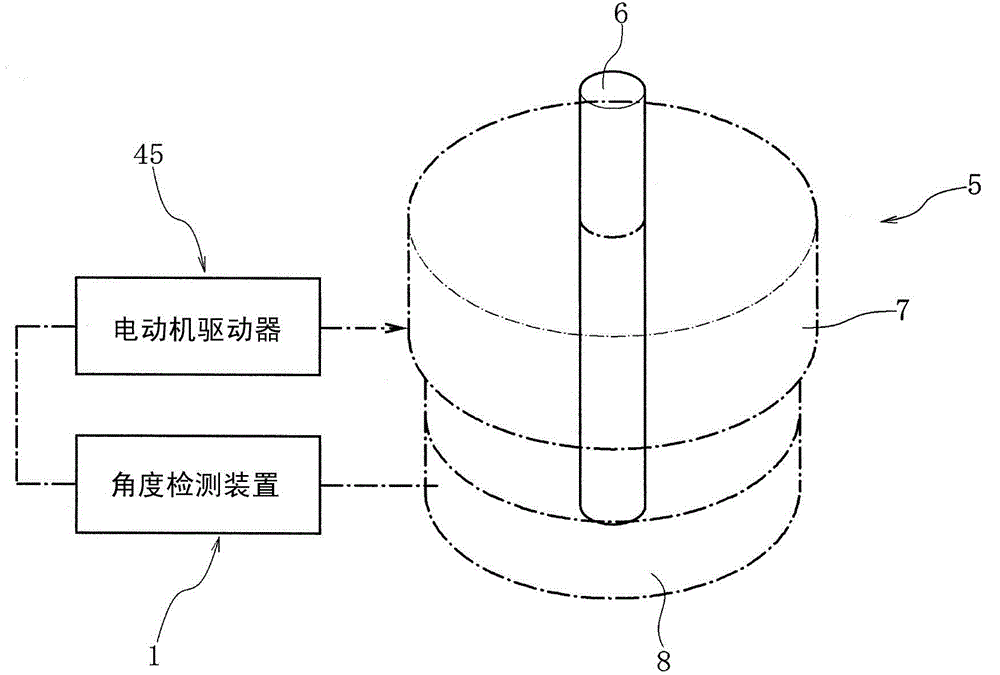

[0063] figure 1 The illustrated motor control device 5 has a rotation shaft 6 , a rotation drive unit 7 that drives the rotation shaft 6 , and a rotation detection unit 8 that detects the rotation of the rotation shaft 6 .

[0064] Such as Figure 8 As shown, the rotation drive unit 7 constitutes a drive unit of the brushless motor, and has a rotor magnet 41 that rotates together with the rotation shaft 6 . Inside the rotor magnet 41 , three-phase stator yokes 42 are arranged at an angle of 120 degrees with respect to the rotation direction, and U-phase, V-phase, and W-phase motor coils 43 are connected to each stator yoke 42 .

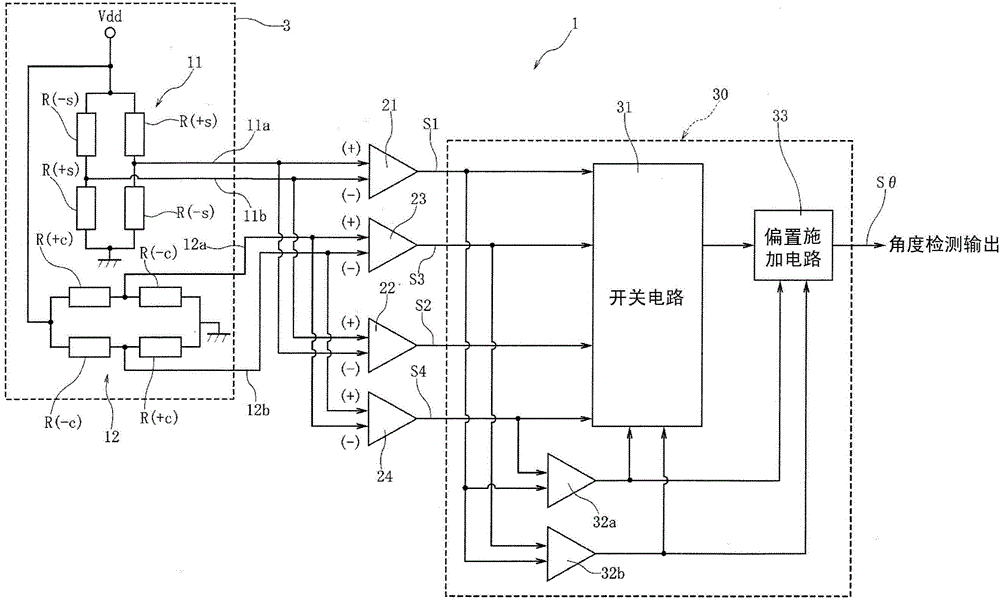

[0065] The rotation detection unit 8 constitutes a part of the angle detection device 1 . The motor driver 45 is controlled by the angle detection output obtained by the angle detection device 1 , and three-phase drive power is applied from the motor driver 45 to the motor coil 43 .

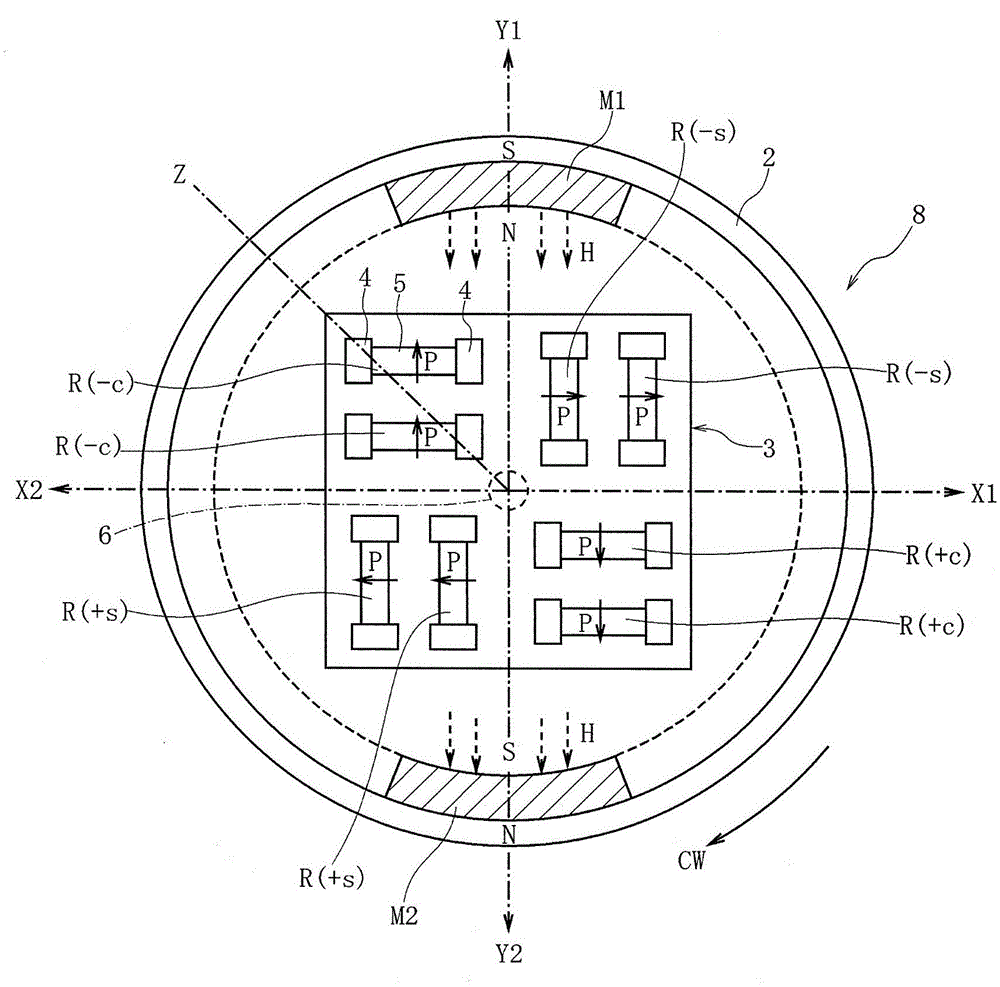

[0066] Such as figure 2As shown, a rotation body 2 that rotate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com