Tobacco leaf culturing and harvesting method

A harvesting method and tobacco leaf technology, applied in the directions of botanical equipment and methods, cultivation, harvesters, etc., can solve the problem that the raw material requirements of the cigarette industry cannot be well met, the harvesting maturity does not meet the technical standards, and the harvesting personnel are mature. Inaccurate control of the degree of control and other problems, to achieve the effect of improving the grade structure and quality level, prolonging the maturing time, and reducing the cost of fertilizer input

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

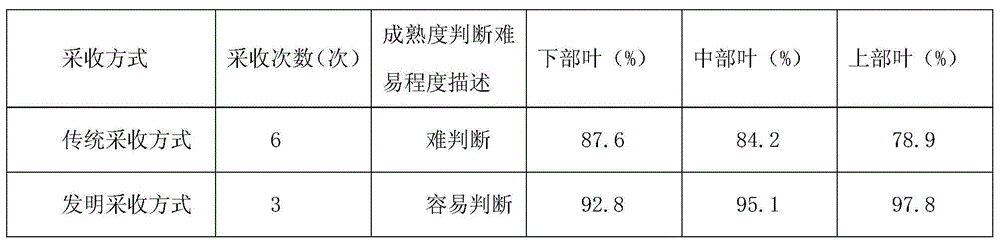

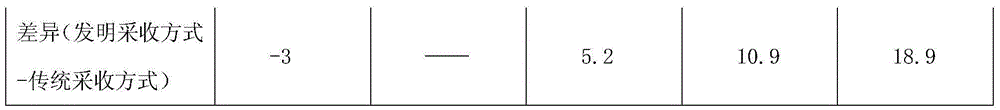

[0016] The invention is based on the conventional planting and harvesting technology, and improves the leaf threshing stage and the picking stage. In the leaf threshing stage, the number of tobacco leaves is controlled at 12-14 pieces, and the tobacco leaves are picked three times in the picking stage.

[0017] Treatment basis: The lower 2-3 leaves of flue-cured tobacco are poor in ventilation and light transmission conditions and insufficient dry matter accumulation, and the upper 2-3 top leaves are poorly opened and tight in tissue structure. The quality is poor, and none of them can meet the requirements of upgrading the cigarette brand structure. In addition, with the increase of labor costs and coal material costs, the selling price and curing cost (labor, coal, etc.) of the lower 2-3 pieces and the upper 2-3 tobacco leaves etc.) are basically the same, and tobacco farmers have no profit to invest, which seriously affects the enthusiasm of farmers to grow tobacco. In the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com