Mechanism used for pulling fungus stick out of fungus bag and applied to solid fungus inoculation machine

A technology of solid strains and bacteria packs, applied in horticulture, botany equipment and methods, plant cultivation, etc., can solve the problems of reducing the survival rate of inoculated bacteria, waste, and carrying out of culture substrates, so as to improve the quality of inoculated bacteria and production Efficiency, avoidance of unnecessary waste, effect of infection control of miscellaneous bacteria

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

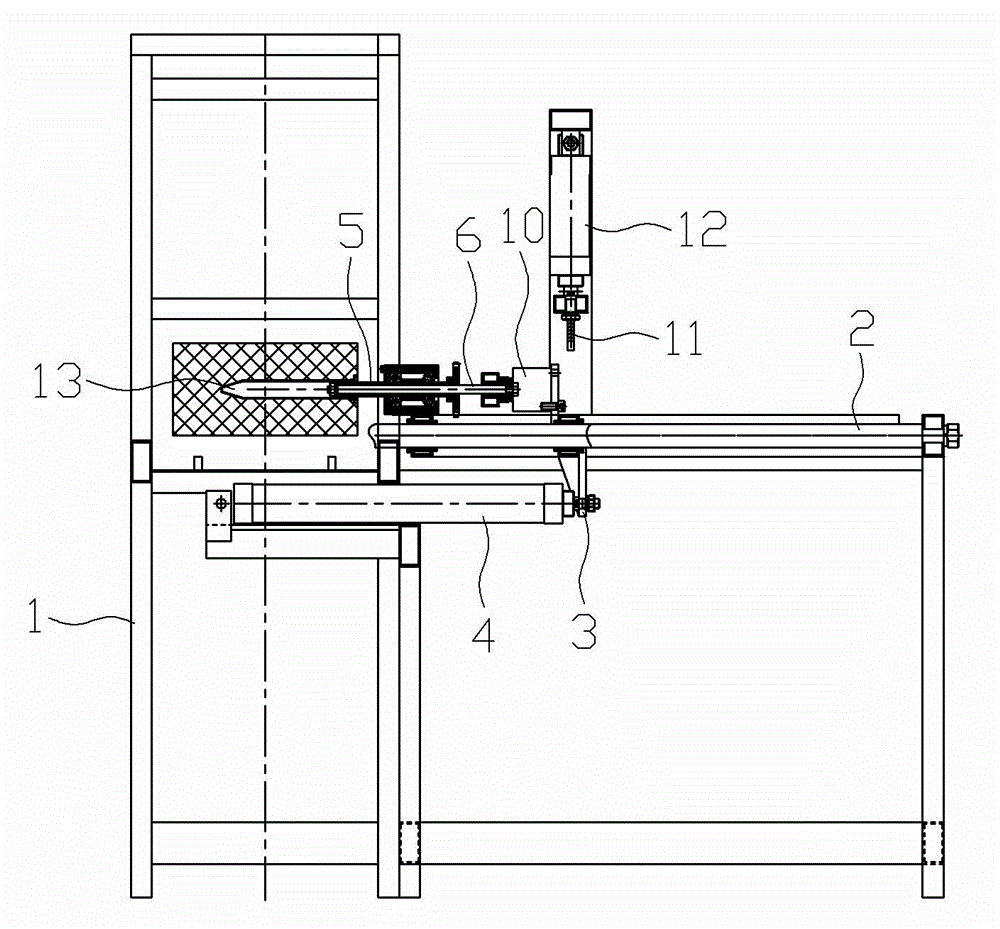

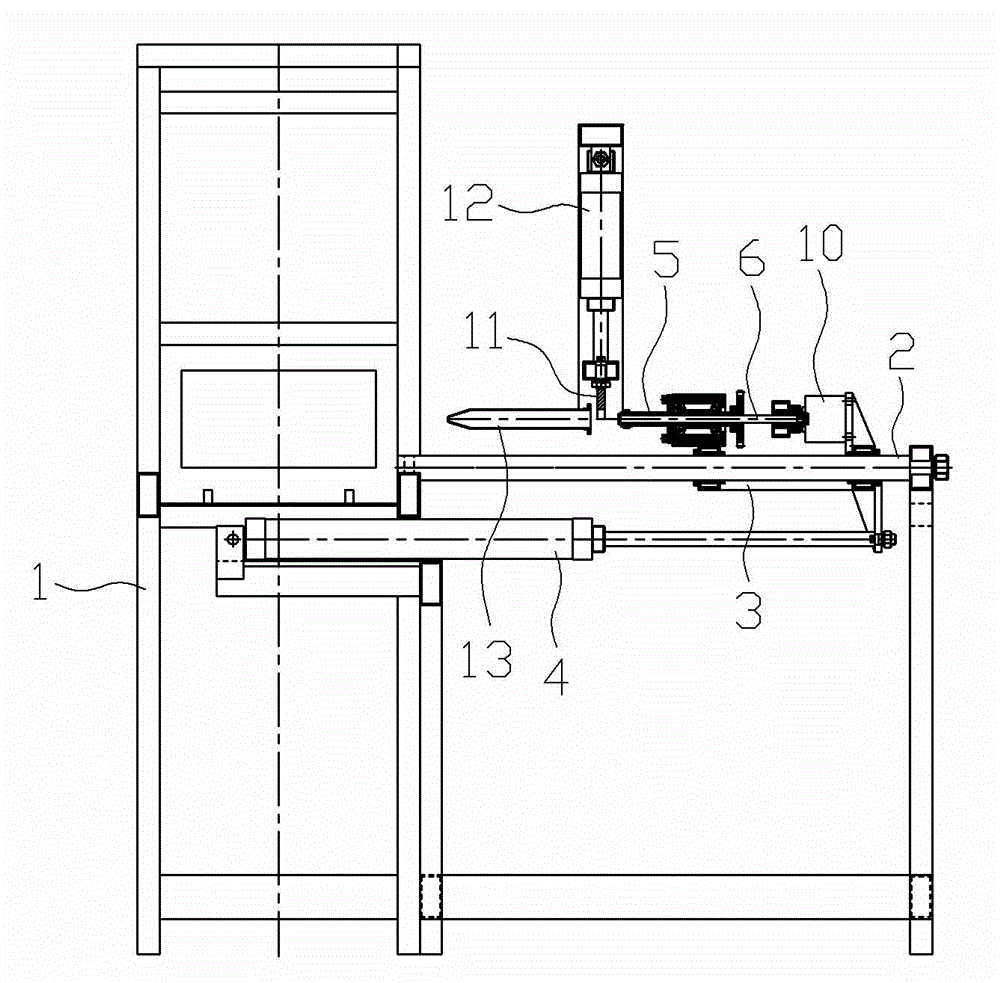

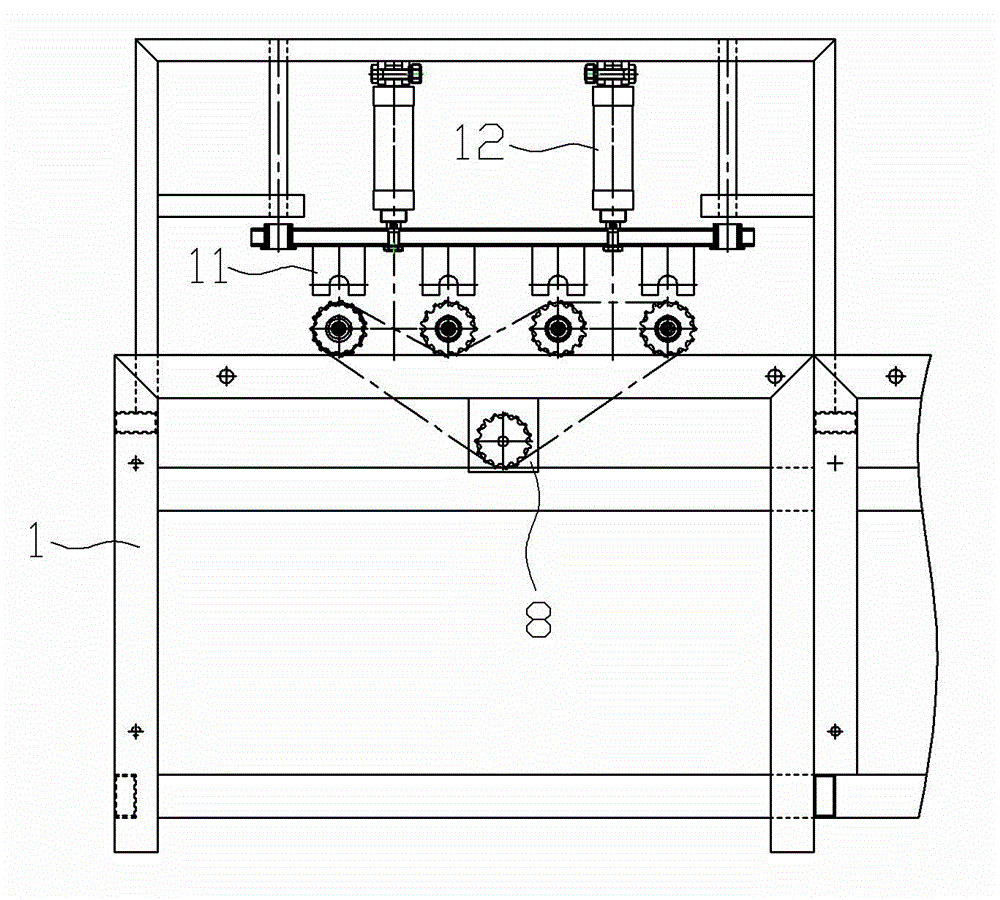

[0012] Such as Figures 1 to 5 As shown, it includes a frame 1 and a conveying device provided with a bacteria bag positioning tray. The conveying device adopts a conveyor belt type, and the bacteria bag positioning tray is fixed on the conveyor belt to run with it. When the station stays, the bacteria bag rod pulling mechanism is set on one side of the conveying device. The conveying direction of the conveying device is fixed on the frame 1, two horizontal guide rods 2 can be used, the sliding carriage 3 is slidably fixed on the horizontal guide rod 2, and the rod pulling cylinder 4 is connected with the sliding carriage 3 And it can be pushed to slide. The expansion rod device is composed of expansion rod sleeve 5, expansion rod shaft 6, expansion ring 7, rotating motor 8 and pull rod device 9. The expansion rod sleeve 5 is rotatably fixed on the sliding bracket 3 through the shaft seat 6. Above, the expansion rod sleeve 5 is connected with the rotating motor 8 to drive its...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com