Automatic stretching type sprinkling irrigation trolley

An extension type, sprinkler irrigation truck technology, applied in the field of agricultural machinery, can solve the problems of high energy consumption, cumbersome and laborious operation, insufficient automation, etc., and achieve the effects of simple operation and management, simple adjustment, and reduced energy consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Further describe the present invention below in conjunction with accompanying drawing.

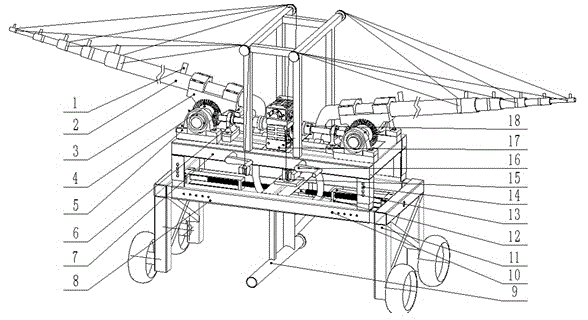

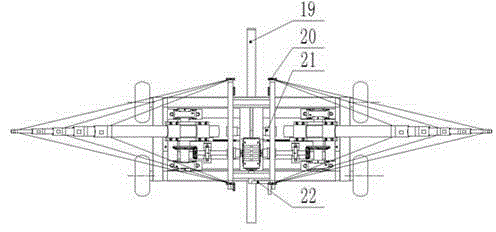

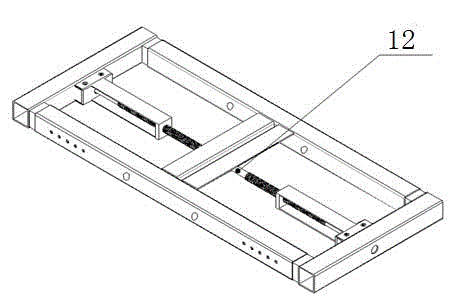

[0023] An automatic extending sprinkler truck, mainly including a vehicle frame, a wire rope clamping mechanism 16, a rocker 22, a deceleration and direction change assembly and an execution assembly, the deceleration and direction change assembly includes a worm gear reducer 17, a shaft coupling device 18, belt seat bearing 6, bevel gear set 4, the rocker 22 is connected to the worm gear reducer 17, and the output shaft of the worm gear reducer 17 is connected to the coupling 18, and the coupling 18 Connect the bearing with seat 6, the bearing with seat 6 is connected with the bevel gear Group 4. The bevel gear Group 4 includes a small spur bevel gear and a large spur bevel gear, the executive assembly includes a seated bearing 5, a hoop 3, a water pipe 2, a spray head 1, the seated bearing 5 and the bevel gear Group 4 connection, the water pipe 2 is fixedly connected to the b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com