Sweetsop extractive preparation method and application of sweetsop extractive in cigarettes

A lychee extract, technology of lychee, applied in the direction of application, tobacco, tobacco processing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

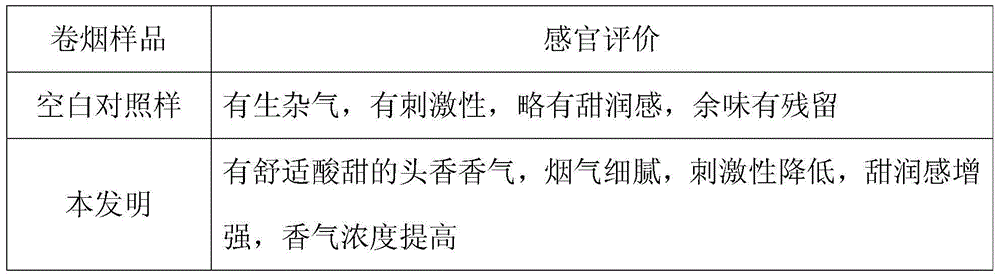

Image

Examples

Embodiment 1

[0022] (1) Accurately weigh 2 kg of peeled custard apples, put them into a juice extractor for beating and crush to obtain custard apple pulp.

[0023] (2) Soak the custard apple pulp with 85wt% ethanol aqueous solution of 4 times its weight, reflux at a temperature of 90° C. for 2 hours, and filter while it is hot. The filter residue is used in the next step, and the filtrate is used for subsequent use.

[0024] (3) Add 30wt% ethanol aqueous solution of 5 times its weight to the filter residue in step (2) for leaching, heat to 90±2°C and reflux for 2h, after filtering while it is hot, repeat the leaching-heating-reflux- for the filter residue Filtrate several times while hot, combine the filtrate obtained each time and concentrate under reduced pressure at 40±2°C to a density of 1.200±0.006g / cm 3 , to obtain concentrate A;

[0025] (4) Mix the concentrate A obtained in step (3) with the filtrate obtained in step (2) and place it at 0°C for 36 hours, then filter it, and conce...

Embodiment 2

[0027] (1) Accurately take by weighing 2kg of peeled custard apples, put into a juice extractor for beating and crush to obtain custard apple pulp.

[0028] (2) Soak the custard apple pulp with 95wt% ethanol aqueous solution of 4 times its weight, reflux at a temperature of 90° C. for 2 hours, and filter while it is hot. The filter residue is used in the next step, and the filtrate is for subsequent use.

[0029] (3) To the filter residue in step (2), add 30wt% ethanol aqueous solution of 5 times its weight, heat to 90±2°C and reflux for 2h, after filtering while hot, repeat the leaching-heating-reflux-filtering while hot to the filter residue Step several times, combine the filtrate obtained each time and concentrate under reduced pressure at 40±2°C to a density of 1.200±0.006g / cm 3 , to obtain concentrate A;

[0030] (4) Mix the concentrate A obtained in step (3) with the filtrate obtained in step (2) and place it at 0°C for 36 hours, then filter it, and concentrate the fil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com