Novel hand-washing solution

A hand sanitizer, a new type of technology, applied in cosmetics, skin care preparations, skin diseases, etc., can solve the problems of high production cost, environmental pollution, large investment, etc., and achieve good frost resistance, advanced formula design, and good stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

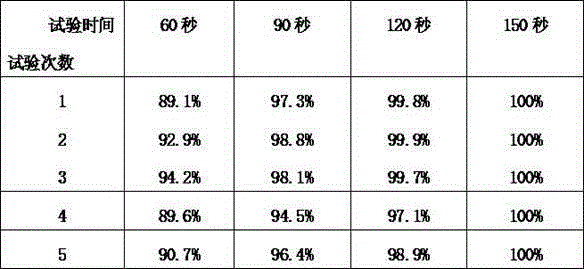

Examples

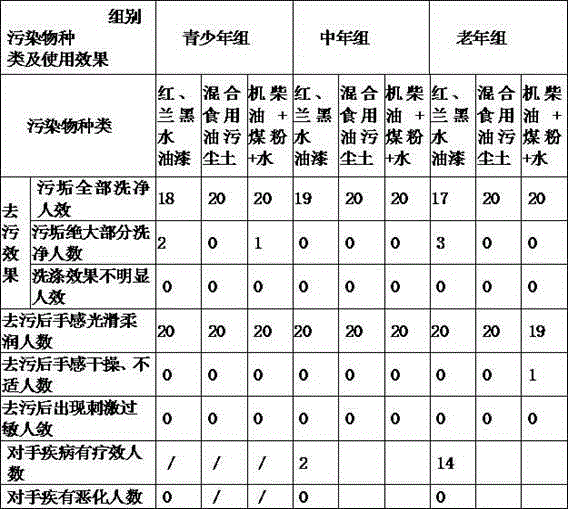

Embodiment 1

[0031] Produce 100kg of new hand sanitizer for the elderly; it is made by blending the following raw material components: tea saponin crystal 5kg, AES 15kg, sucrose ester 1kg, citric acid 0.3 kg, CAB-35 2 kg, AOS 3 kg, EDTA- 2Na 0.1 kg, Kayson 0.2 kg, fragrance 0.4 kg, NaCl 3 kg, deionized water 70 kg; the manufacturing process is as follows: first prepare the buffer with deionized water and NaCl, and add tea soap to the buffer at 80-90 °C Then add AES, 6501, citric acid, CAB-35, AOS, EDTA-2Na, Kaisong and essence in sequence, and then stir to form a gel emulsion; cool to room temperature to obtain detergent; after packaging and inspection, Product storage.

Embodiment 2

[0033]Produce 100kg of new hand sanitizer for middle-aged people; it is made by blending the following raw material components: tea saponin crystal 20kg, AES 6kg, sucrose ester 5kg, citric acid 0.2 kg, CAB-35 1 kg, AOS 1 kg, EDTA -2Na 0.4 kg, Kayson 0.1 kg, fragrance 0.3 kg, NaCl 1 kg, deionized water 65kg; the manufacturing process is as follows: first prepare the buffer with deionized water and NaCl, and add tea soap when the buffer is at 80-90°C Then add AES, 6501, citric acid, CAB-35, AOS, EDTA-2Na, Kaisong and essence in sequence, and then stir to form a gel emulsion; cool to room temperature to obtain detergent; after packaging and inspection, Product storage.

Embodiment 3

[0035] Produce 100kg of new hand sanitizer for teenagers; it is made by blending the following raw material components: tea saponin crystal 8kg, AES 10kg, sucrose ester 3kg, citric acid 0.2 kg, CAB-35 4kg, AOS 2kg, EDTA-2Na 0.2 kg , Kaisong 0.3 kg, essence 0.3 kg, NaCl 2 kg, deionized water 70kg; the manufacturing process is as follows: first prepare the buffer with deionized water and NaCl, add tea saponin crystals to the buffer at 80-90°C, stir Dissolve; then add AES, 6501, citric acid, CAB-35, AOS, EDTA-2Na, Kethon and essence in sequence, and then stir to form a gel emulsion; cool to room temperature to obtain detergent; after packaging and inspection, the finished product is put into storage.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com