Method for preparing dendrobium officinale super micropowder

A technology of Dendrobium officinale and ultrafine powder is applied in the directions of medical preparations containing active ingredients, powder delivery, pharmaceutical formulations, etc., which can solve problems such as destroying ingredients, and achieve the effects of increased absorption, less consumption and high yield.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

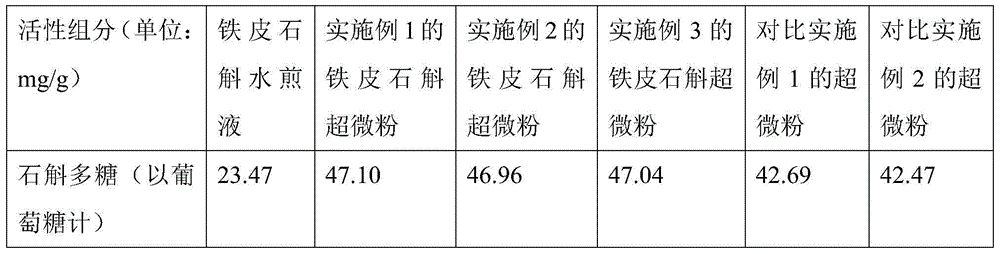

Examples

Embodiment 1

[0026] 1) Pretreatment: Take fresh Dendrobium officinale medicinal materials, remove impurities, wash with water, and cut into 2~4cm sections;

[0027] 2) Low-temperature freezing: spread out the Dendrobium officinale section obtained in step (1) for freezing, and the freezing temperature is -5°C.

[0028] 3) Low-temperature pulverization: the Dendrobium officinale section obtained in step (2) is pulverized at a low temperature of -5°C, and sieved to obtain 40-100 mesh coarse powder.

[0029] 4) Low-temperature vacuum microwave drying: The crude Dendrobium officinale powder obtained in step (3) is dried by low-temperature vacuum microwave, the power is turned on, and the microwave power is adjusted: 1kw, total microwave drying time, 2h, drying temperature: -5°C; vacuum degree: 0.04Pa. In the microwave drying process, a microwave treatment method of 30s interval and 30s heating can be adopted (that is, the heating is stopped for 30s every 30s, and then the heating is continued for 30...

Embodiment 2

[0034] 1) Pretreatment: Take fresh Dendrobium officinale medicinal materials, remove impurities, wash with water, and cut into 2~4cm sections;

[0035] 2) Low temperature freezing: spread the Dendrobium officinale section obtained in step (1) for freezing, and the freezing temperature is -40°C.

[0036] 3) Low-temperature pulverization: the Dendrobium officinale section obtained in step (2) is pulverized at a low temperature of -40°C, and sieved to obtain coarse powder of 40-100 mesh.

[0037] 4) Low-temperature vacuum microwave drying: The crude Dendrobium officinale powder obtained in step (3) is dried by low-temperature vacuum microwave, the power is turned on, and the microwave power is adjusted: 15kw, total microwave drying time, 0.5h, drying temperature: -40℃; vacuum degree : 0.09Pa. During the microwave drying process, a microwave treatment method with an interval of 30s and heating for 30s can be adopted (that is, the heating is stopped for 30s every 30s, and then the heatin...

Embodiment 3

[0042] 1) Pretreatment: Take fresh Dendrobium officinale medicinal materials, remove impurities, wash with water, and cut into 2~4cm sections;

[0043] 2) Low-temperature freezing: spread out the Dendrobium officinale section obtained in step (1) for freezing, and the freezing temperature is -20°C.

[0044] 3) Low-temperature pulverization: The Dendrobium officinale section obtained in step (2) is pulverized at a low temperature of -20°C and sieved to obtain coarse powder of 40-100 mesh.

[0045] 4) Low-temperature vacuum microwave drying: The crude Dendrobium officinale powder obtained in step (3) is dried by low-temperature vacuum microwave, the power is turned on, and the microwave power is adjusted: 6kw, total microwave drying time: 1h, drying temperature: -20°C; vacuum degree: 0.06Pa. During the microwave drying process, a microwave treatment method of 30s interval and 30s heating can be adopted (that is, the heating is stopped for 30s every 30s, and then the heating is continu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap