Continuous roll-forming method of constant-thickness curved surface

A roll forming, equal-thickness technology, applied in the field of metal plastic processing, can solve the problems of uneven strength distribution, weak strength, and easy damage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The working process and implementation steps of the present invention will be further described below in conjunction with the accompanying drawings.

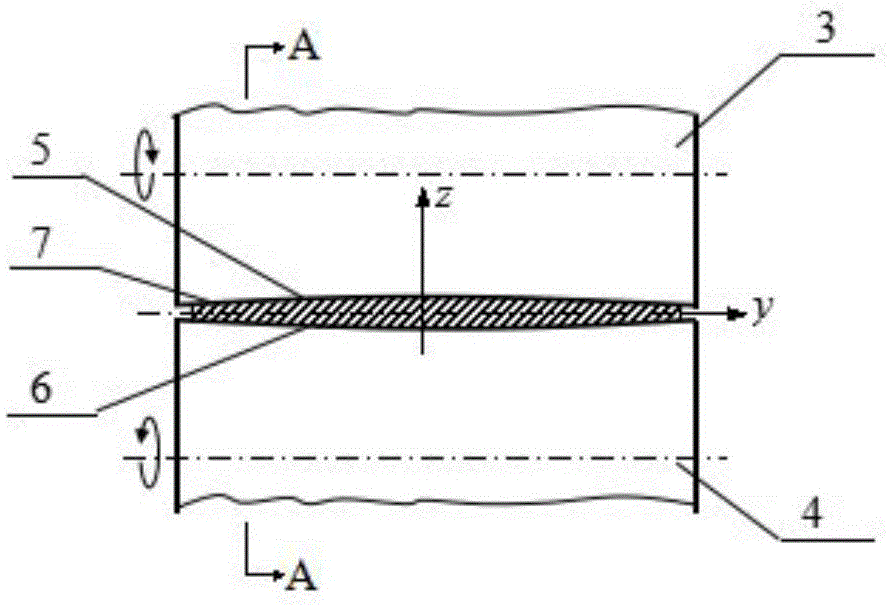

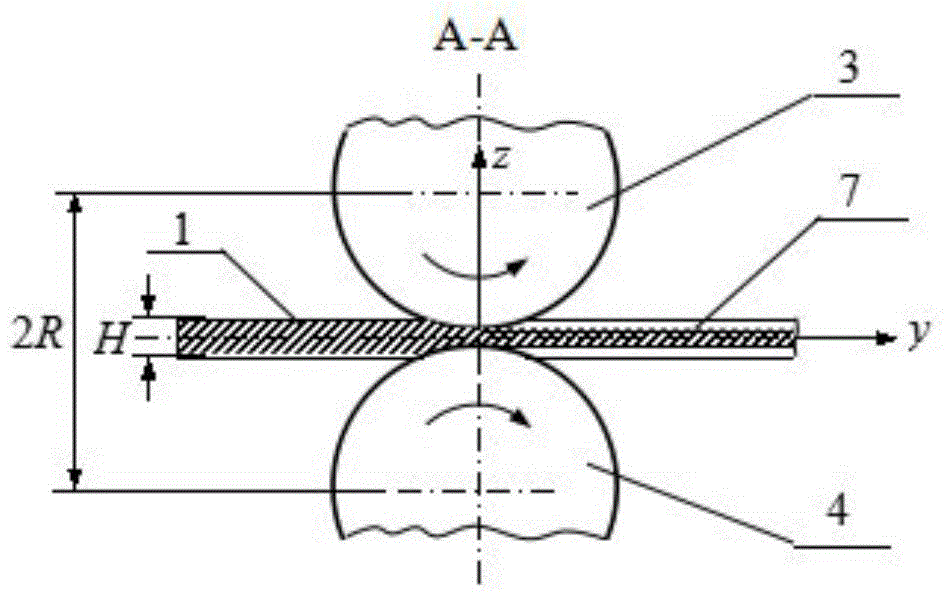

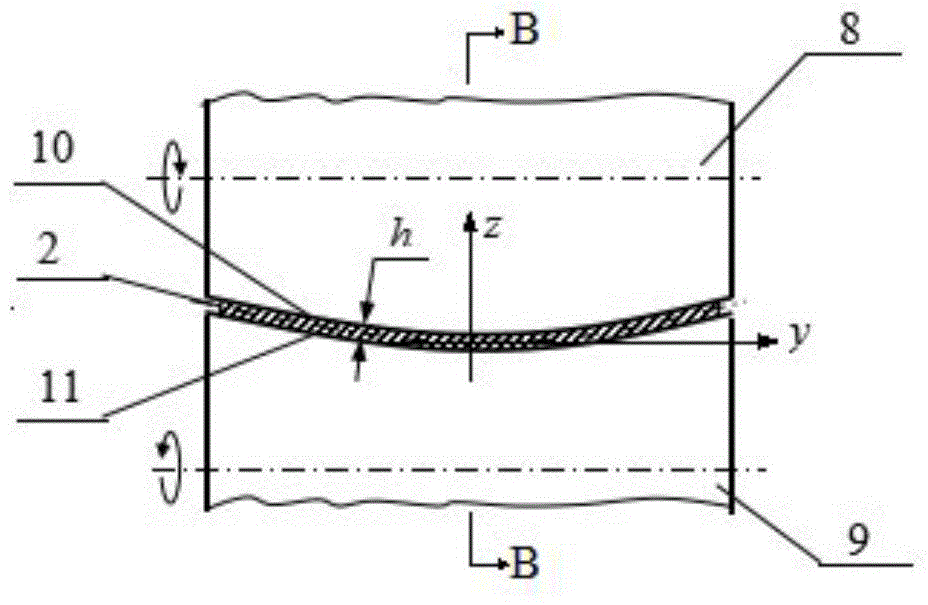

[0041] Such as Figure 1a , 1b , 2a and 2b, the continuous roll forming process of equal-thickness curved surfaces involved in the present invention is realized by two-pass rolling, and the sheet material 1 passes through two-pass continuous rolling of work rolls with a convex (or concave) profile, A three-dimensional curved surface part 2 with equal thickness is formed.

[0042] Such as Figure 1a , 1b As shown, the first pass of rolling is completed by a pair of upper work roll I3 and lower work roll I4 with the same concave roll profile, and a straight roll gap with variable gap along the transverse direction is formed between the upper and lower work rolls; in addition ,Such as Figure 4b As shown, the rolling of the first pass can also be completed by a pair of upper work roll III10 and lower work roll III11 with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com