Lead-acid storage battery grid edge cutting tool

A lead-acid battery and grid technology, applied in the field of lead-acid battery grid trimming tooling, can solve the problems of poor connection between grid surface and active material, easy movement of grid, limited clamping force, etc. Long life, good connection firmness, not easy to move

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

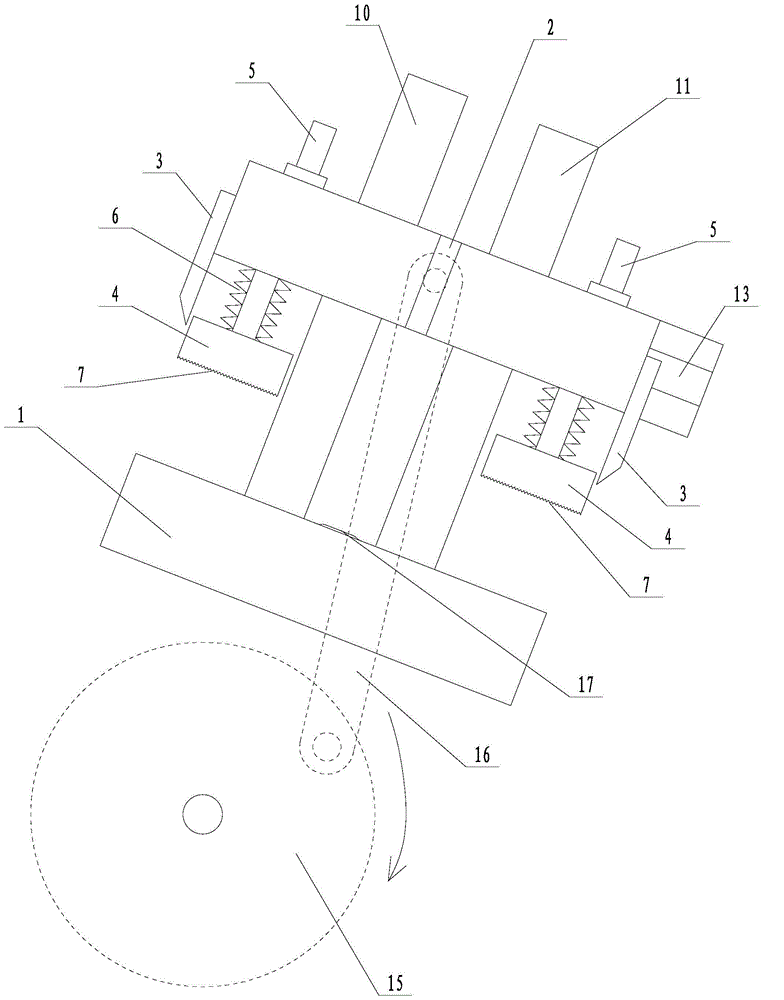

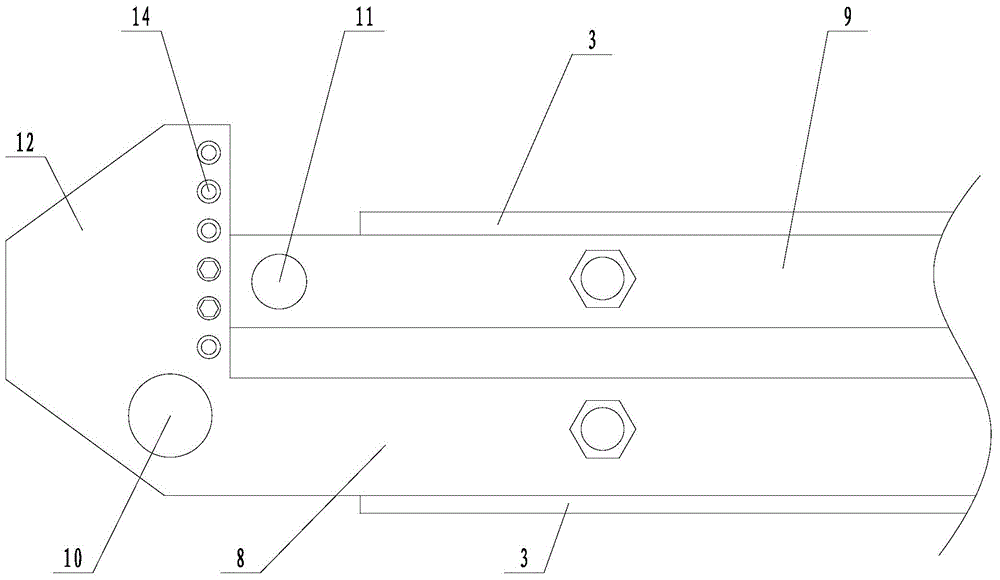

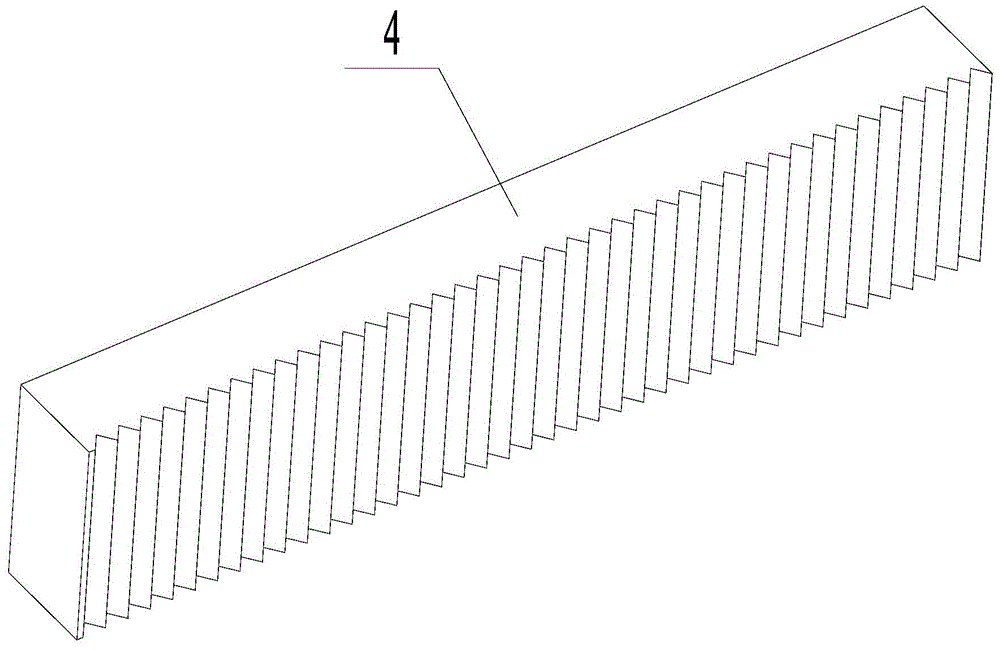

[0020] Example 1: A lead-acid battery grid trimming tooling (see attached figure 1 ), including the support base 1, the long strip mobile pressing base 2, the support base and the mobile pressing base are both inclined, and the support base is vertically connected with a number of guide posts, and the guide posts are movably sleeved on the two ends of the mobile pressing base to move The pressure seat is connected with a driving mechanism that pushes the movable pressure seat to move up and down. The driving mechanism includes a driving wheel 15 and a connecting rod 16. Both ends of the movable pressure seat are hinged with a connecting rod, and the lower ends of the two connecting rods are respectively hinged on the driving wheel close to At the edge position, the driving wheel is driven by a motor. A cutter 3 is fixedly connected to the opposite two side walls of the movable pressing seat. The cutter head of the cutter is arranged under the lower surface of the movable pressin...

Embodiment 2

[0022] Embodiment 2: A lead-acid battery grid trimming tooling. Its structure is similar to that of Embodiment 1. The main difference is that the indentation molding surface in this embodiment is a frosted surface. The frosted surface increases the pressing force between the pressing plate and the grid, and can also form frosted indentations on the surface of the grid. In the process of pressing the grid, the local pressure will not be too large to crush the grid. The other structure is the same as the first embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com