Thin-wall round pipe turning fixture

A round tube, thin-walled technology, applied in the field of pressing fixtures, can solve the problems affecting dimensional accuracy and geometric tolerance, thermal deformation of thin-walled round tubes, weak strength, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

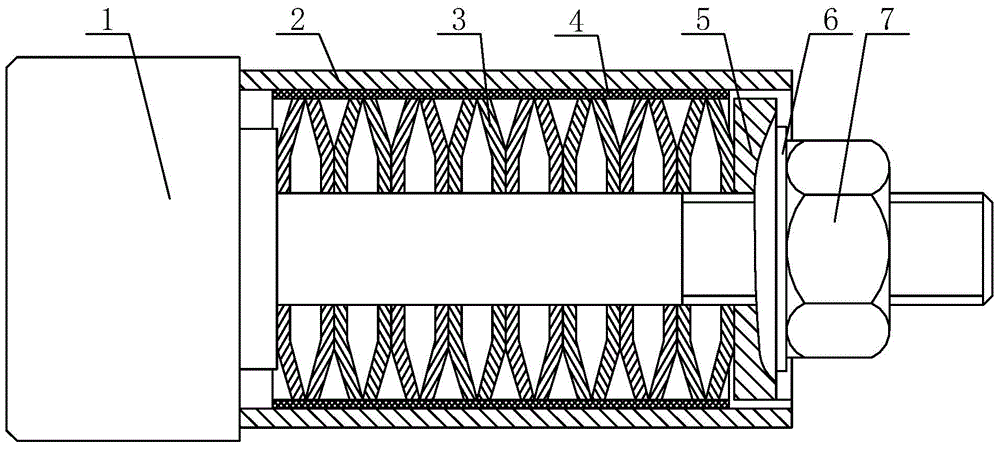

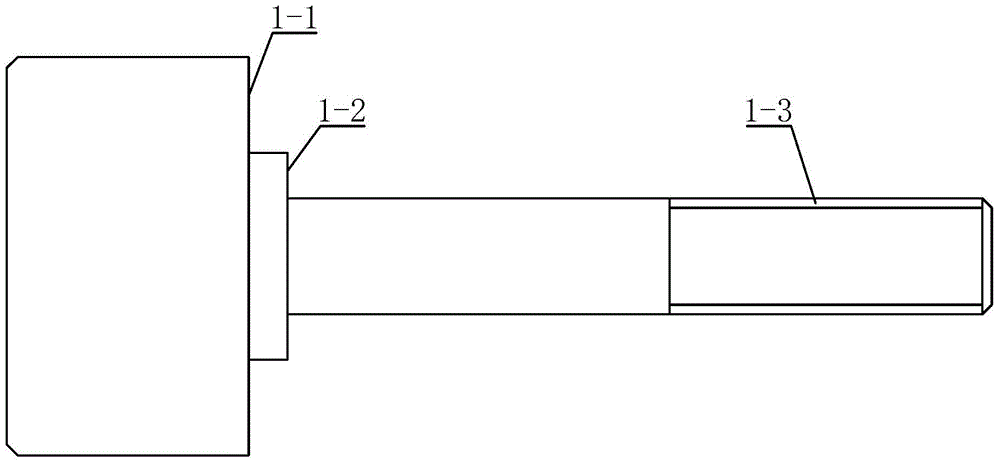

[0020] Such as figure 1 and figure 2 A thin-walled circular tube turning fixture shown includes a stepped mandrel 1, a plurality of disc springs 3 and a pressure plate 5 for pressing the disc springs 3; one end of the stepped mandrel 1 is sequentially provided with a workpiece positioning platform 1-1 and butterfly spring pad 1-2, the other end of the stepped mandrel 1 is provided with an external thread 1-3, and the stepped mandrel 1 is fitted with a plurality of Process the disc spring 3 of the thin-walled round tube 2, the outer side of the disc spring 3 is provided with an elastic rubber sleeve 4 for increasing the friction between the disc spring 3 and the thin-walled tube 2 to be processed, the stepped mandrel 1 is located One side of the disc spring 3 is provided with a pressure plate 5 that applies an axial pre-tightening force to the disc spring 3, and the stepped mandrel 1 is provided with a pressure plate on the side of the pressure plate 5 that cooperates with th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com