Lockset hole drilling die

A technology of locks and molds, which is applied in the direction of drilling molds for workpieces, etc., which can solve the problems that molds are not easy to be recycled and reused, damage the outer surface material of holes, and the opening size of locks is easy to deviate, so as to save manpower, reduce costs, save The effect of manpower and material resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] Preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

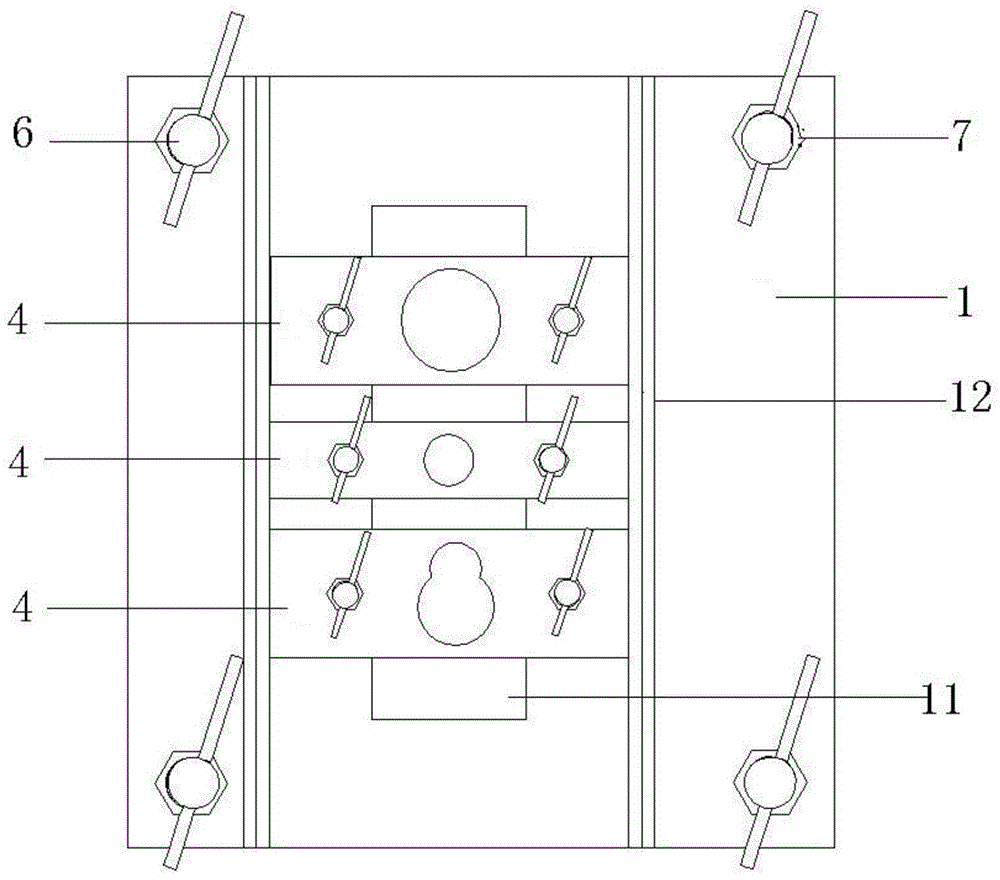

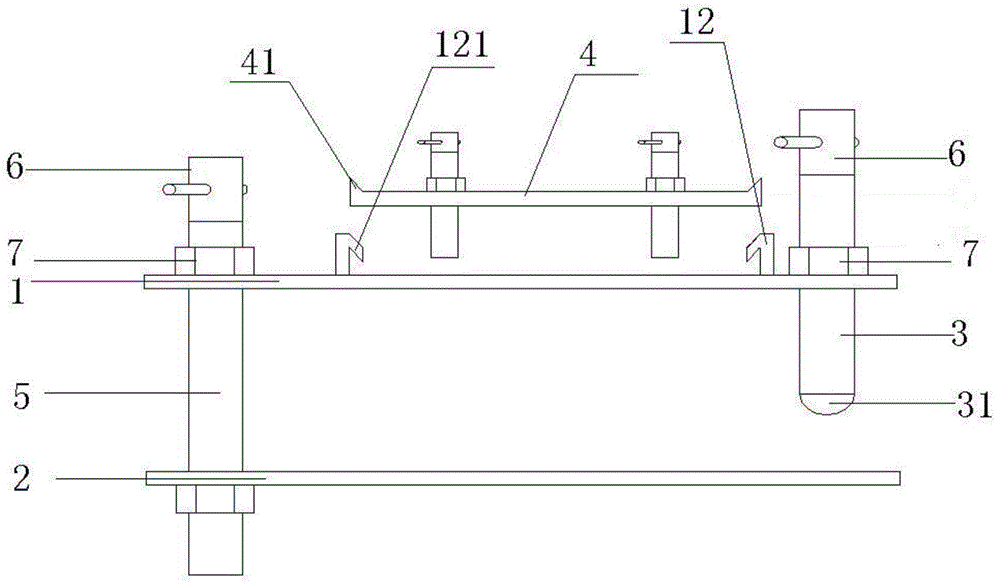

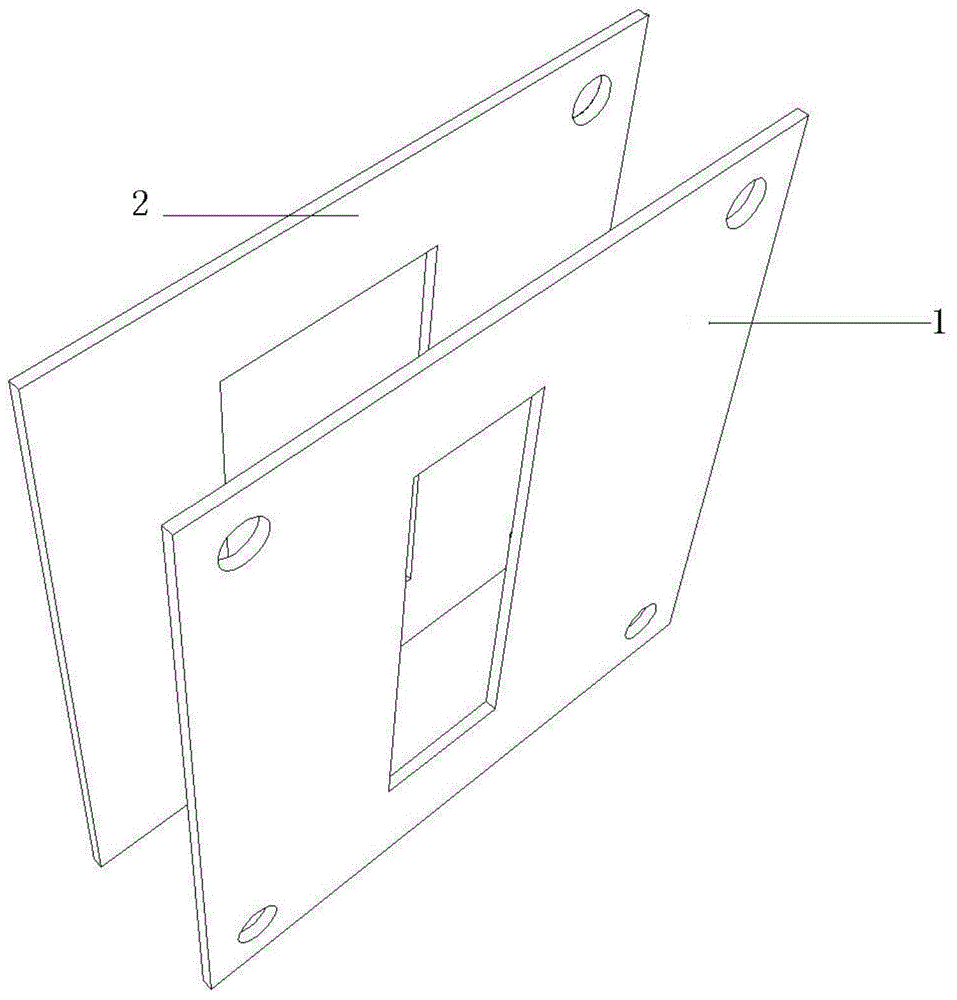

[0045] In order to achieve the purpose of the present invention, as Figure 1-9 As shown, in some embodiments of the lock opening mold of the present invention,

[0046] The lock opening mold includes: a first positioning plate 1 , a second positioning plate 2 , a clamping column 3 , and a hole opening template 4 .

[0047] The first positioning plate 1 is provided with a first through hole 11, and the second positioning plate 2 is arranged below the first positioning plate 1 by a fixed connector 5, and the fixed connector 5 is connected with the first positioning plate 1, The second positioning plate 2 is fixedly connected, and fixed by using a special wrench to turn the screw 6 and the nut 7 to ensure that the fastening of each accessory is not loose. Simultaneously, when the width of the article that needs to unlock the hole is greater t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com