Electric soldering iron with conveying mechanism

A technology of feeding mechanism and electric soldering iron, which is applied in the direction of soldering iron, tin feeding device, metal processing equipment, etc. It can solve problems such as inaccurate positioning, falling off, excessive solder joints, etc., and achieve the effect of preventing uneven tin output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described in detail below in conjunction with the accompanying drawings by means of specific embodiments:

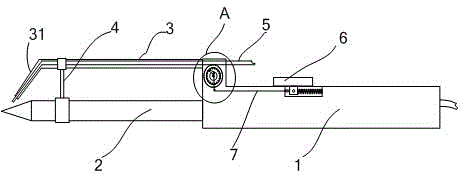

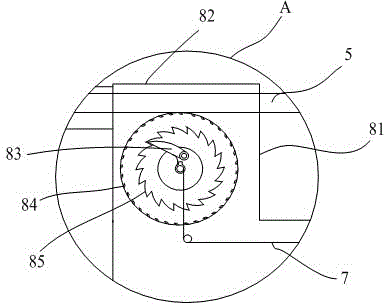

[0014] like figure 1 and figure 2 As shown, the electric soldering iron with a feeding mechanism includes an electric soldering iron composed of a handle 1, a heating wire tube and a soldering iron rod 2. A spring switch 6 is provided on the handle 1, and a ratchet feeder is provided at the junction of the handle 1 and the soldering iron rod 2. The ratchet feeder includes a feeding tube 3, a feeding ratchet and a housing 81. The feeding ratchet arranged in the housing 81 is an internal meshing ratchet and includes a ratchet claw 83 and an outer ring 85. The rotation center of the ratchet claw 83 is connected to the handle 1 by a coil spring. The edge of the ring 85 is provided with feeding teeth 84 inclined to one end of the soldering iron rod. The upper surface of the shell 81 is an arc-shaped half-pipe 82, and a tin wire w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com